Composite bus traveling cable for port machinery elevator

A technology of accompanying cables and machinery, applied in the direction of insulated cables, bendable cables, flat/ribbon cables, etc., to achieve the effects of improving service life and safety, reliable electrical performance and transmission characteristics, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

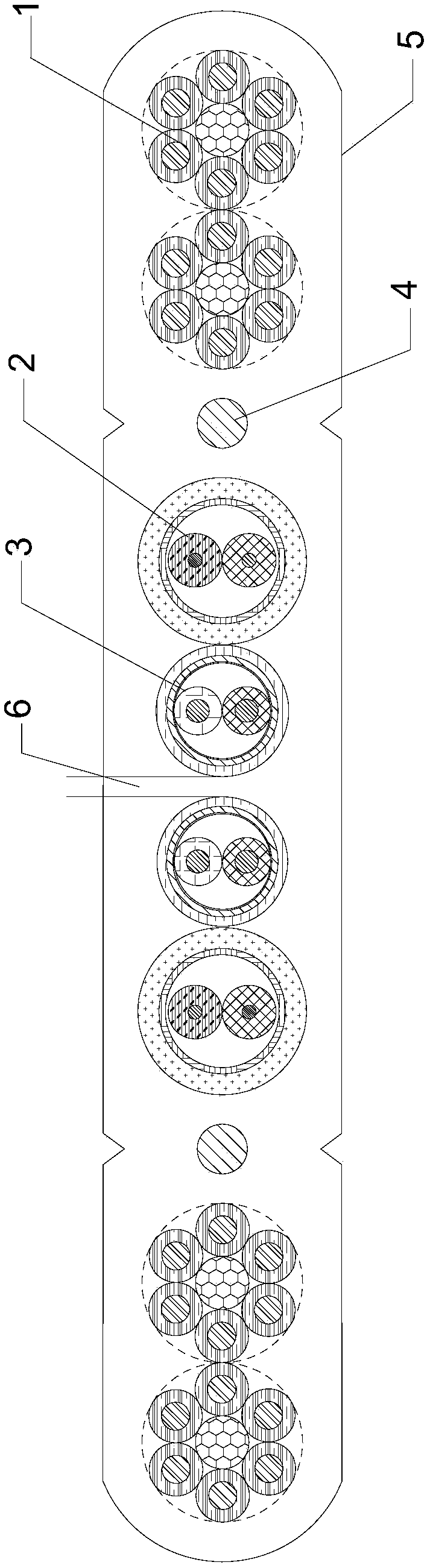

[0019] see Figure 1 to Figure 4 According to the present invention, the composite bus accompanying cable for port machinery elevator includes an outer sheath and a plurality of cable units arranged in the outer sheath.

[0020] The outer sheath includes an oblate sheath body 5 and a spacer 6 arranged in the middle of the sheath body 5 . The sheath body 5 is made of environmentally friendly wear-resistant elastic material.

[0021] A plurality of cable units are arranged side by side in the sheath body 5, and the sheath body 5 is used to fix and protect the plurality of cable units.

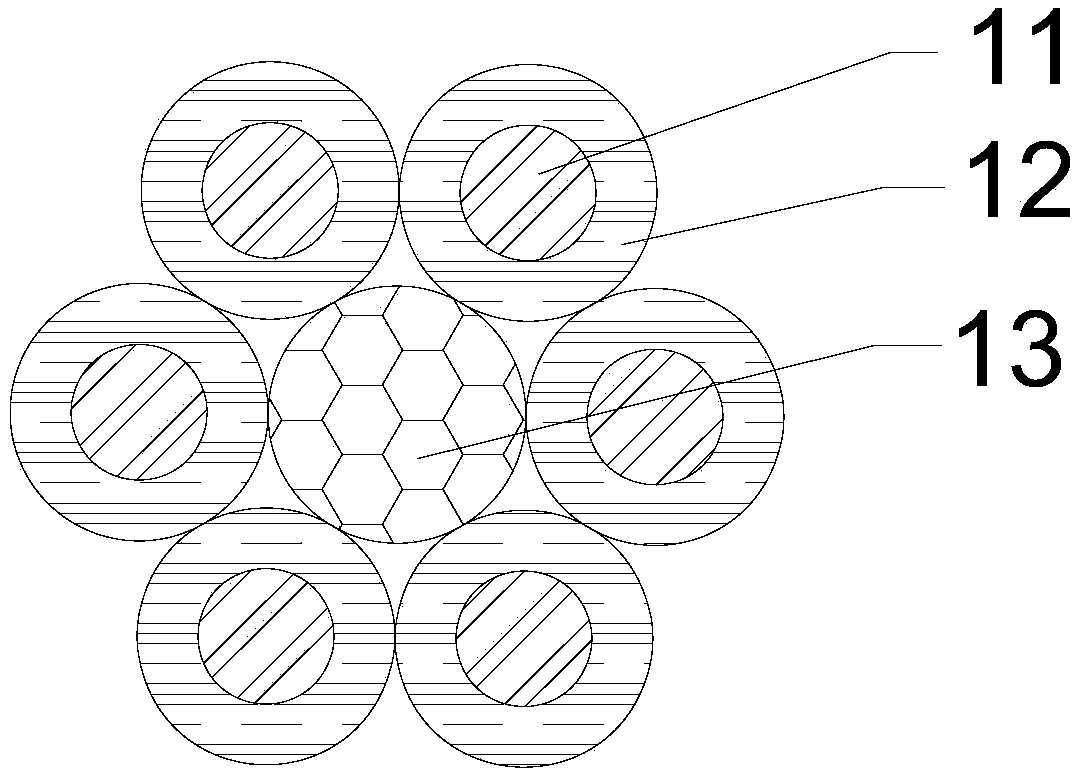

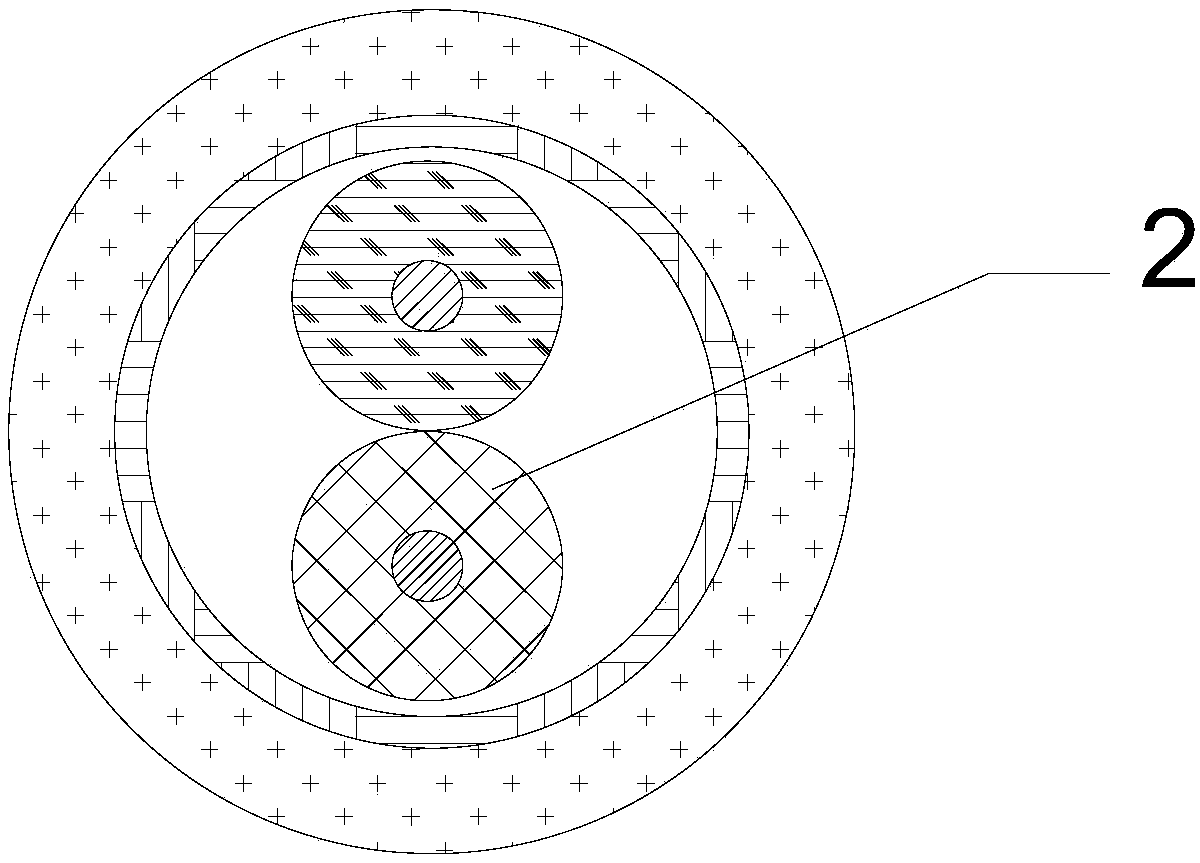

[0022] Multiple cable units include two pairs of shielded wires 3, two communication bus cables 2 and four wire groups 1, wherein the two shielded wire pairs 3 are arranged in the middle of the sheath body 5 and symmetrically located on both sides of the spacer 6. side. Each pair of shield...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com