A method and a device for detect defects of a die casting part

A defect detection and die-casting technology, which is applied in computer parts, image data processing, instruments, etc., can solve problems such as mutual interference, poor detection environment, and false detection, so as to improve efficiency and accuracy, enhance edge features, and improve detection efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

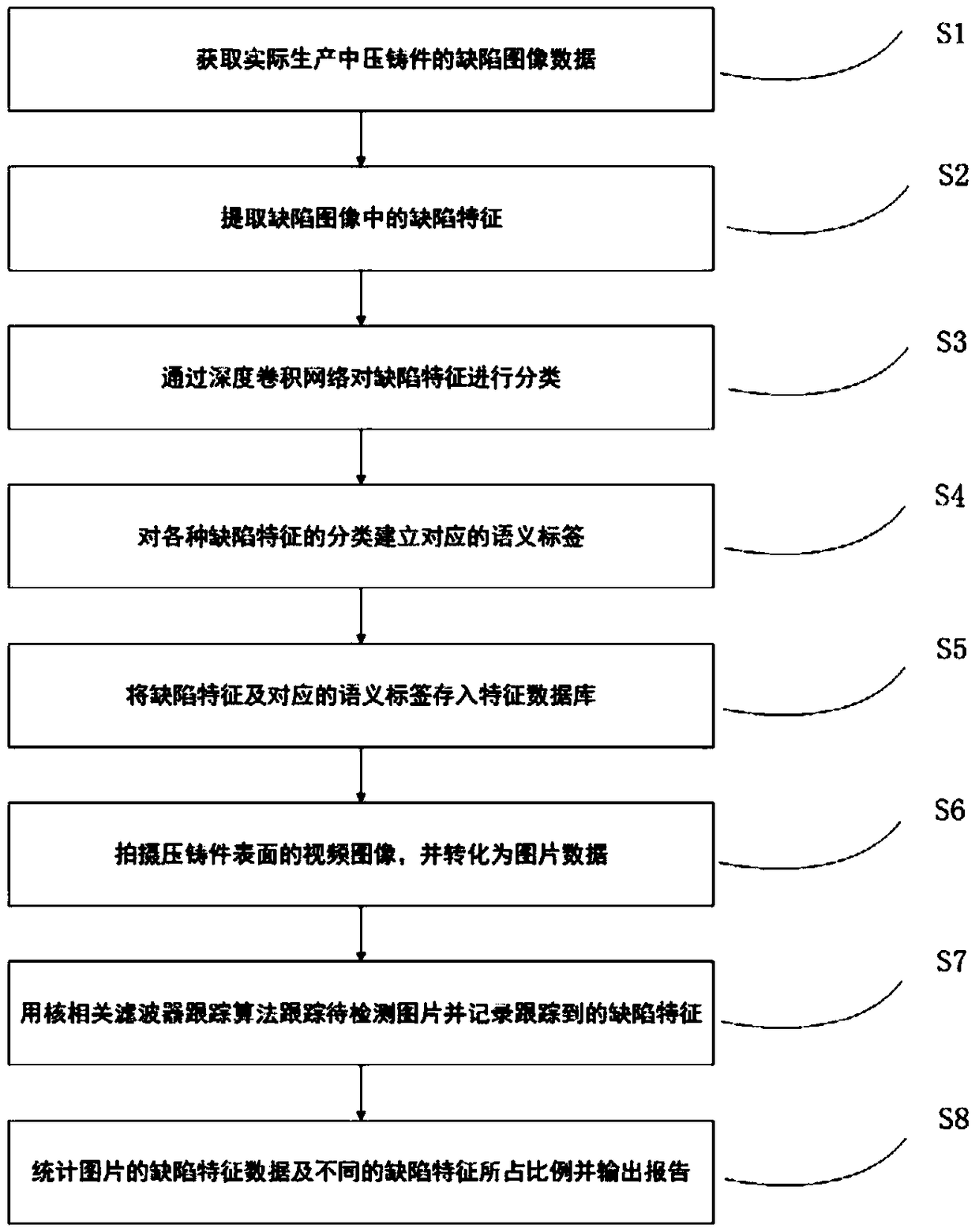

[0043] see figure 1 , which is a flow chart of a die casting defect detection method according to an embodiment of the present invention.

[0044] A method for detecting defects in die castings according to the present invention, comprising:

[0045] S1 acquires defect image data of die castings in actual production;

[0046] S2 extracting defect features in the defect image;

[0047] S3 classifying the defect features;

[0048] S4 establishes corresponding semantic labels for the classification of various defect features; M represents fuzzy defects, and oil stains and water stains belong to fuzzy defects, which can be represented by MY and MS, and so on for other types of defects;

[0049] S5 stores the defect features and corresponding semantic tags into a feature database;

[0050] S6 takes video images of the die casting surface and converts them into picture data;

[0051] S7 uses a kernel correlation filter tracking algorithm to track the picture data, takes the defec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com