Reversing sealing device of low-temperature-resistant combined ring spacer sleeve valve rod forming valve

A sealing device and low-temperature-resistant technology, which is applied in the direction of valve operation/release device, valve device, valve housing structure, etc., can solve the problem of long-time energization of the electromagnetic coil, heat generation, increase in the load of the electromagnetic coil, and increase in the instantaneous resistance of the valve stem and other problems, to achieve the effects of enhancing the sensitivity of the reversing, reducing the running resistance, and solving the reliability of the valve reversing and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

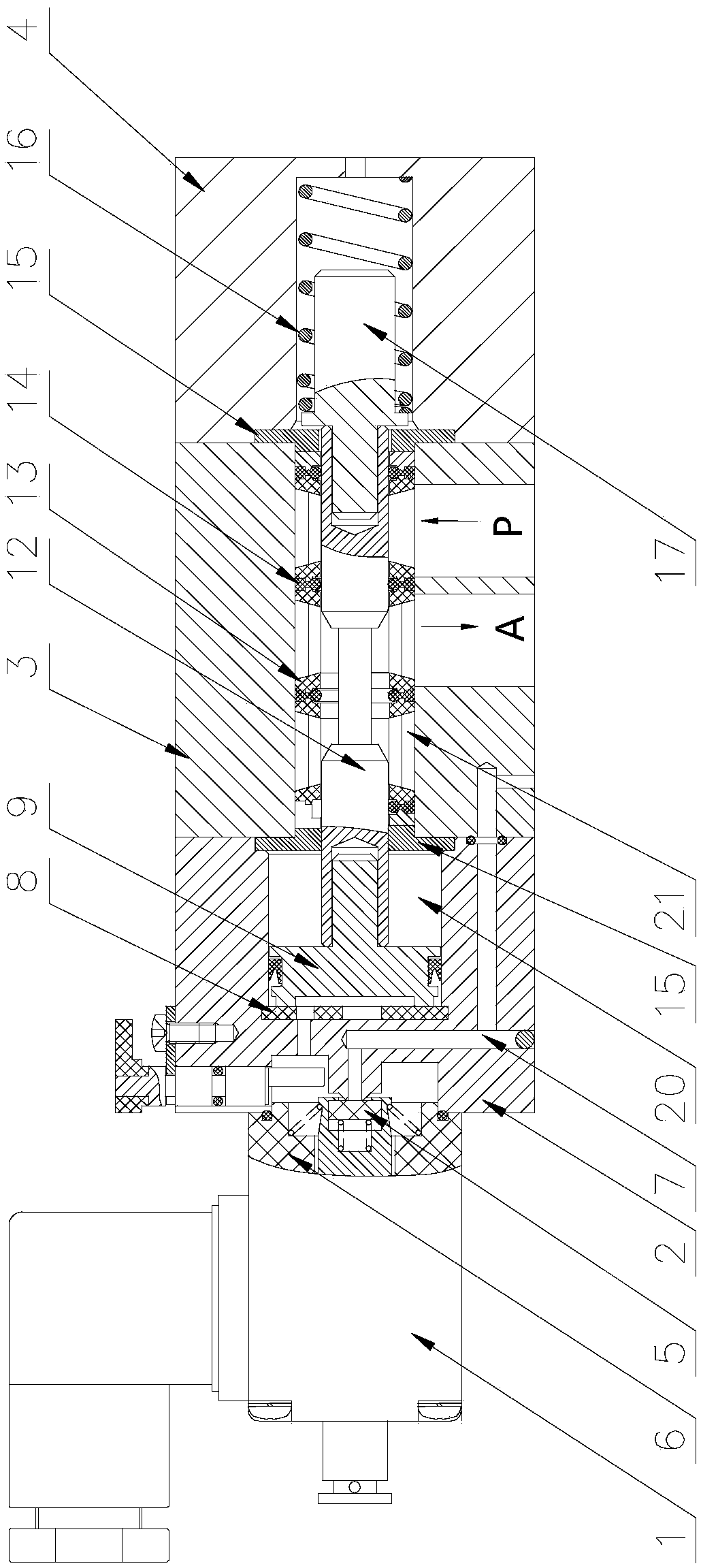

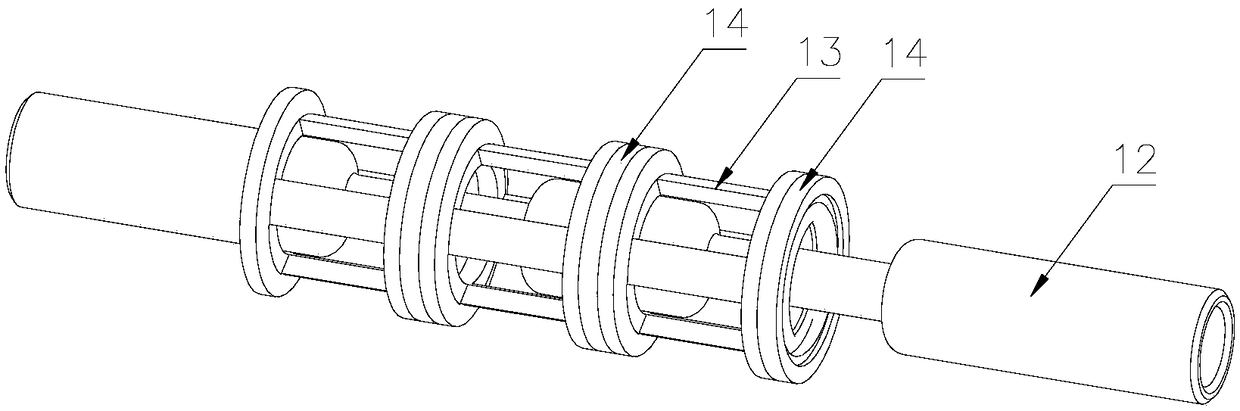

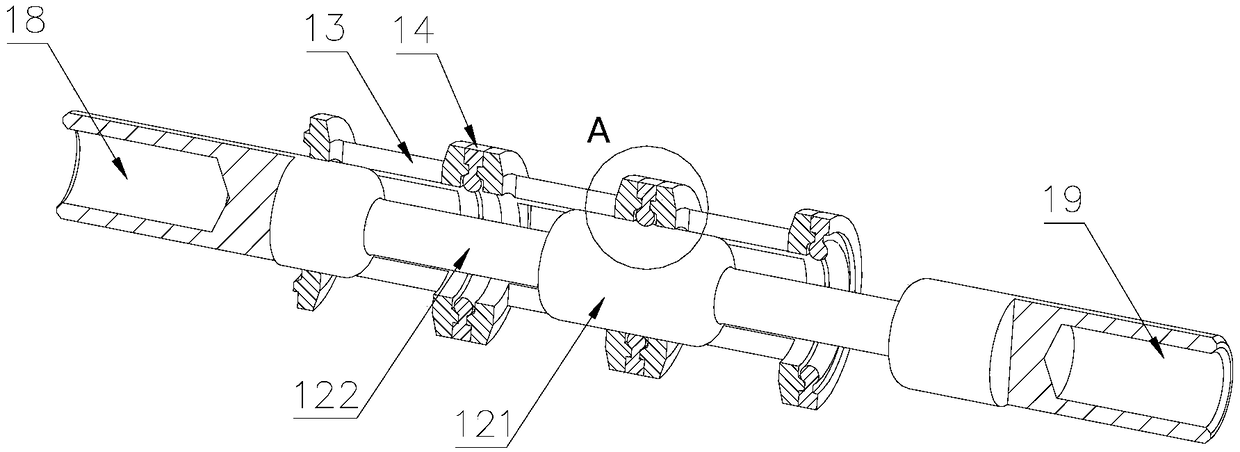

[0039] A valve reversing sealing device composed of a low-temperature resistant combination ring 14 spacer 13 and a valve stem 12, including an electromagnetic pilot valve 1, a valve seat 2, a valve body 3, a valve stem 12, and an end cover 4. One side of the valve seat 2 An electromagnetic pilot valve 1 is provided, and the electromagnetic pilot valve 1 is provided with a movable iron core inside, and the end face 134 of the movable iron core 5 is provided with a gasket, and an electromagnetic coil 6 is wound around the movable iron core; the valve seat 2 One side is provided with an air intake passage 7, and one end of the air intake passage 7 communicates with the outside world, and the other end forms a sealing structure with the gasket of the movable iron core 5; the inside of the valve seat 2 is provided with an air intake chamber 20, the A piston 9 is arranged inside the intake chamber 20, and the section of the piston 9 is an offset T-shape;

[0040] One side of the va...

Embodiment 2

[0055] The difference from Example 1 is that the gap between the end face 134 of the spacer 13 and the lip 143 of the low temperature resistant combination ring 14 is 0.2 mm.

[0056] The included angle between the inner ring of the boss 133 and the end face 134 is 120°, which not only ensures the reversing sensitivity of the valve stem 12 in two directions, but also ensures that the low-temperature resistant combination ring 14 and the valve stem 12 are formed when the lip 143 moves. The tightness between.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com