Low-cis polybutadiene rubber, preparation method thereof, hips resin, preparation method thereof, and abs resin

A technology of polybutadiene rubber and cis-polybutadiene, which is applied in the fields of ABS resin, low-cis polybutadiene rubber and its preparation, can solve the problems of difficulty in obtaining impact resistance and the like, and achieve high solution viscosity, The effect of high impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022]The second aspect of the present invention provides a method for preparing the above-mentioned low-cis polybutadiene rubber, the method comprising:

[0023](1) In a non-polar hydrocarbon solvent, in the presence of an organolithium initiator and a structure regulator, 1,3-butadiene is subjected to anionic solution polymerization reaction, and the conversion rate of 1,3-butadiene is 99% or more to obtain a polybutadiene active chain with a number average molecular weight of 102,000-130,000; the molar ratio of 1,3-butadiene to the organic lithium initiator is 1800-2500:1;

[0024](2) In the presence of a coupling agent, subject the product of the anionic solution polymerization reaction to a coupling reaction; the molar ratio of the coupling agent and the organolithium initiator is 0.1-0.2:1;

[0025](3) In the presence of a terminator, the product of the coupling reaction is terminated.

[0026]According to the present invention, the preparation method of the low-cis polybutadiene rubber w...

Embodiment 1

[0079]This example is used to illustrate the LCBR rubber of the present invention and its preparation method.

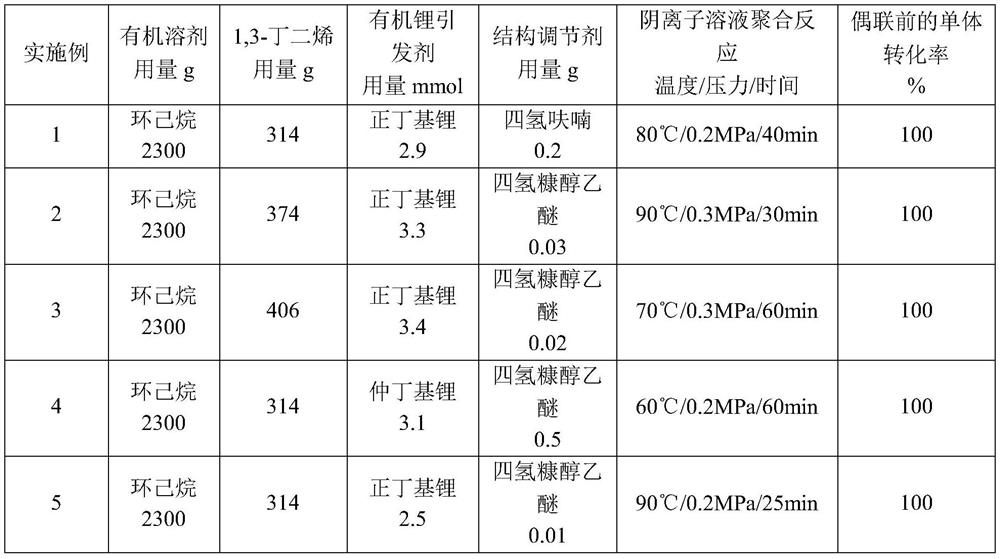

[0080](1) Under the protection of nitrogen, add non-polar hydrocarbon solvents, 1,3-butadiene monomers and structure modifiers (types and dosages are shown in Table 1, the dosages listed in the table are all measured as pure compounds) Inside the reactor, add the organolithium initiator after heating to the specified temperature (see Table 1 for the type and amount, and the amounts listed in the table are all measured as pure compounds), and then carry out the anionic solution polymerization reaction at this temperature and the specified reaction pressure (The conditions are shown in Table 1) to obtain the monomer conversion rate shown in Table 1;

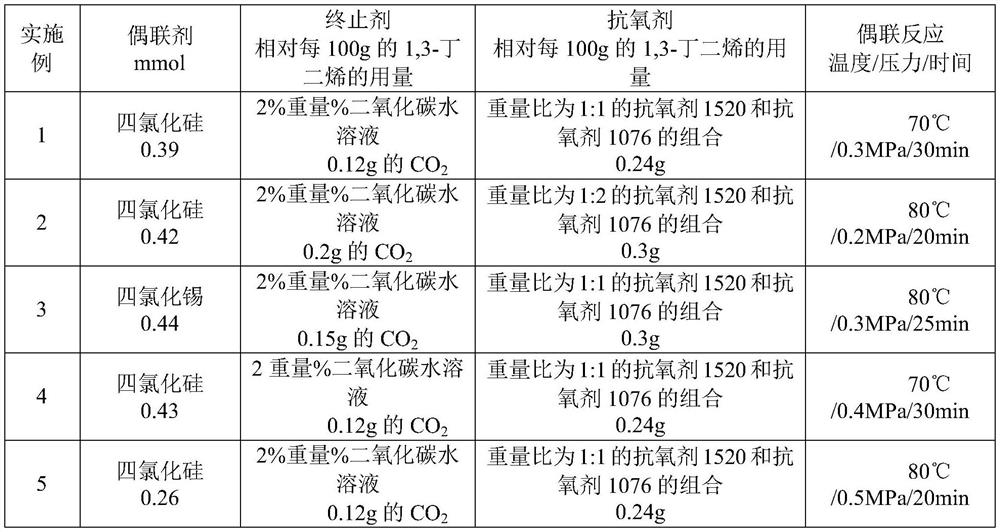

[0081](2) Then the coupling agent is added to the product of the anionic solution polymerization reaction (see Table 2 for its type and amount, and the amounts listed in the table are all measured as pure compounds) to carry out the ...

Embodiment 2-5

[0084]This example is used to illustrate the LCBR rubber of the present invention and its preparation method.

[0085]According to the method described in Example 1, the difference is that the parameters shown in Tables 1 and 2 are used for the reaction to obtain LCBR rubber PB2-PB5, respectively. The structure and performance of the obtained polymer are measured. The results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| izod impact strength | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com