Reclaimed water treatment system for thermal power plant circulating cooling water

A technology of circulating cooling water and treatment system, applied in the field of water treatment, can solve problems such as great harm, and achieve the effects of removing biological residues, not easy to scale, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

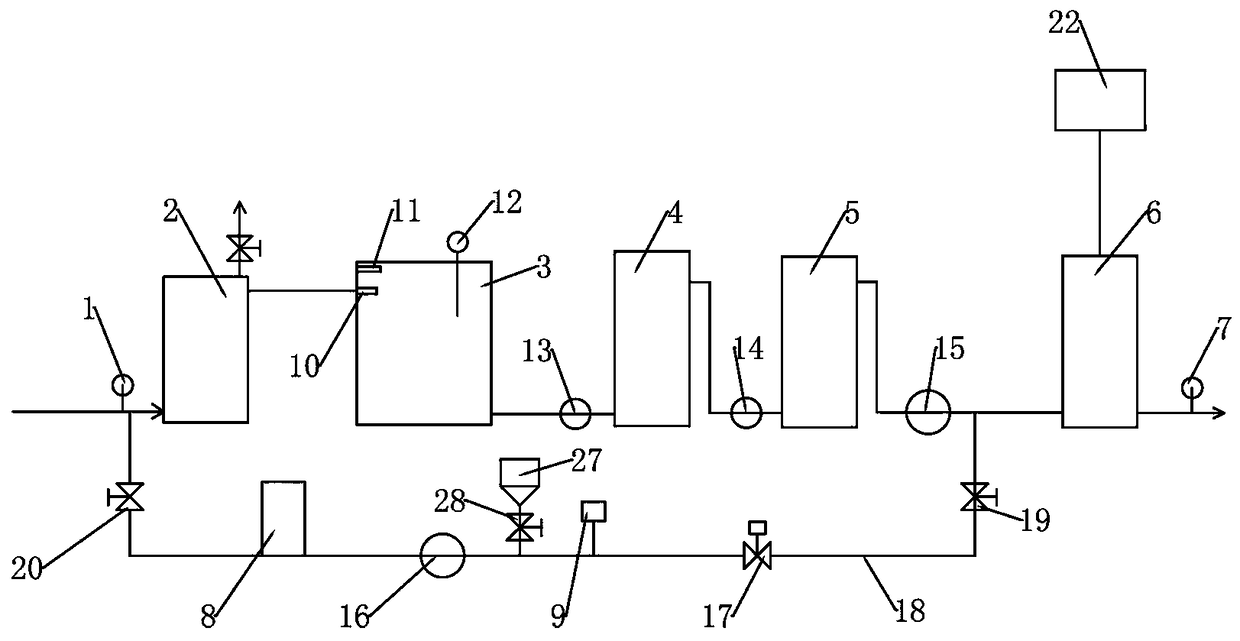

[0027] Embodiment 1: A kind of reclaimed water treatment system for power plant circulating cooling water, see Figure 1 to Figure 2 , including activated carbon tank 4, resin tank 5 and reverse osmosis filter 6, also includes sand filter tank 2, ultraviolet treatment tank 3 and backwashing device;

[0028] The water inlet of the sand filter tank 2 is connected with the reclaimed water to be treated, the water outlet of the sand filter tank 2 is connected with the water inlet of the ultraviolet treatment tank 3 through a pipeline, and the water outlet of the ultraviolet treatment tank 3 is connected with the water inlet of the activated carbon tank 4 through a pipeline Connected, the water outlet of activated carbon tank 4 is communicated with the water inlet of resin tank 5 through pipelines, the water outlet of resin tank 5 is communicated with the water inlet of reverse osmosis filter 6 through pipelines, and the concentrated water outlet of reverse osmosis filter 6 Connect...

Embodiment 2

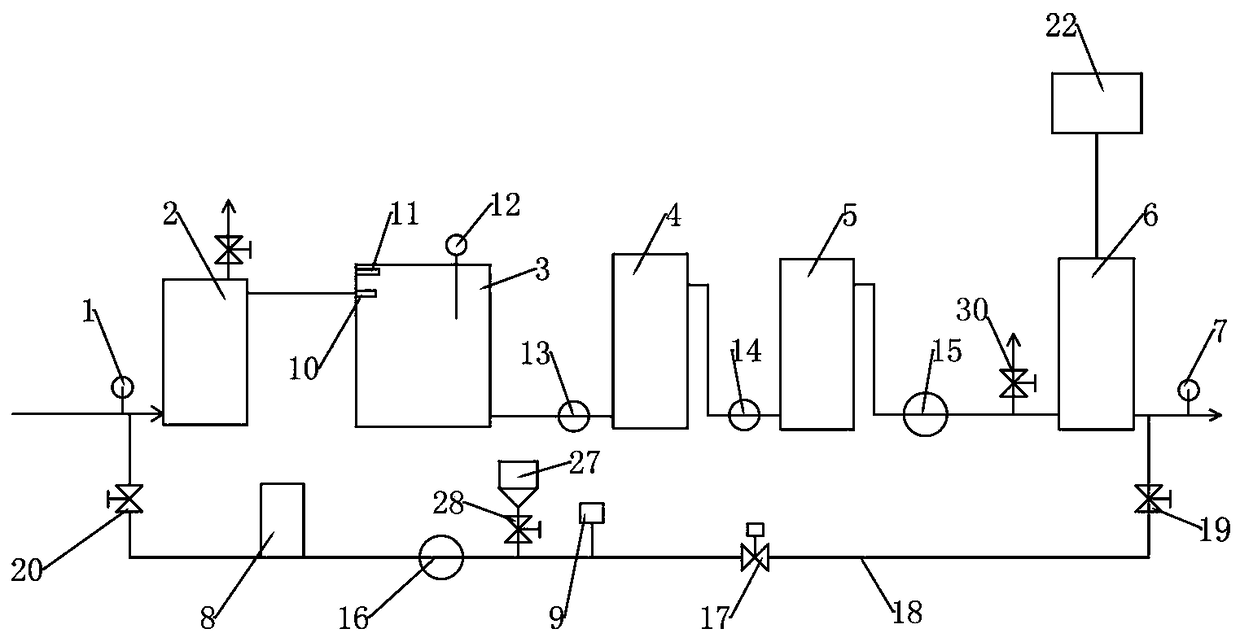

[0038] Embodiment 2: The working principle of this embodiment is the same as that of Embodiment 1, the specific difference is that, see image 3, the water outlet end of the backwashing device is communicated with the clear water outlet port when the reverse osmosis filter 6 is filtered through the bypass pipe 18, and the water inlet end of the reverse osmosis filter 6 is communicated with a sewage pipe 27, and the sewage pipe 27 is provided with There is a blowdown valve. In this embodiment, the backwashing device can only backwash the reverse osmosis filter 6 , and the sewage after the reverse osmosis filter 6 has been washed is discharged through the blowdown pipe 30 .

[0039] After the reverse osmosis filter 6 works for a long time, it is easy to deposit and wash particles on the membrane element, which makes the permeability of the membrane element worse. The backwash device can be used to directly flush the membrane element. When using it, open the valve 1 20 and valve 2...

Embodiment 3

[0040] Embodiment 3: The working principle of this embodiment is the same as that of Embodiments 1 and 2, the specific difference is that this embodiment is further improved on the basis of Embodiment 1 combined with Embodiment 2, see Figure 4 , the water outlet end of the backwashing device is communicated with the water inlet end and the clear water outlet end when the reverse osmosis filter 6 is filtered through the bypass pipe 18 simultaneously, and the water outlet of the thick water pool 22 is communicated with the reclaimed water to be treated by the return pipe 29, in The return pipe is provided with a pump three 23 and a return valve 26.

[0041] The water return pipe 29 is connected with the sand filter 2 water outlet through the sand filter cleaning pipe, the water return pipe 29 is connected with the water outlet of the activated carbon tank 4 through the activated carbon tank cleaning pipe, and the sand filter cleaning pipe is provided with a valve 425. The tank ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com