Conductive large-strain carbon nanotube composite film as well as preparation method and test method thereof

A technology of carbon nanotube composite and carbon nanotube film, which is applied in the field of preparation and strain research, can solve the problem of small strain of single-walled carbon nanotube composite film, and achieve increased difficulty in compounding, good electrical conductivity, and improved mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

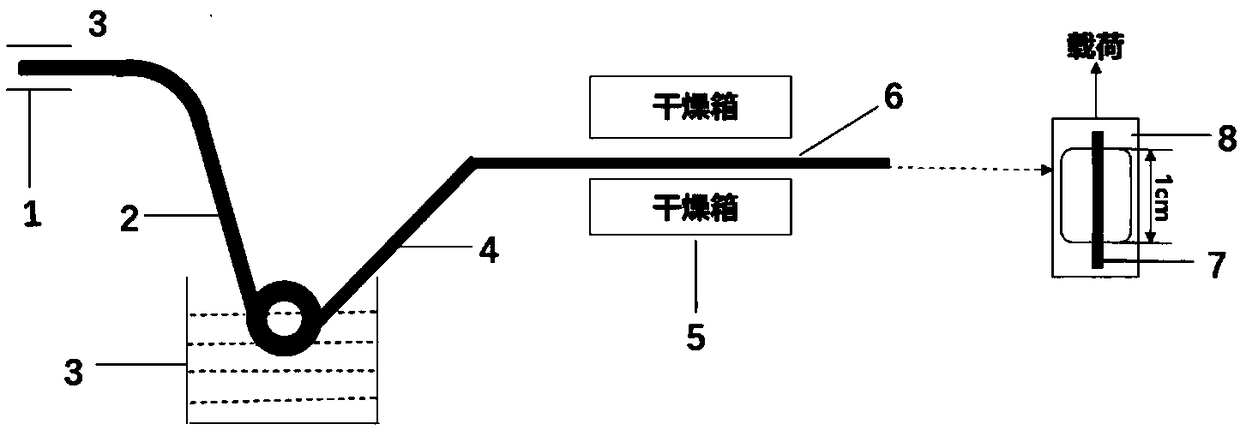

[0028] like figure 1 Shown, the preparation method of conductive large-strain carbon nanotube composite film comprises the following steps:

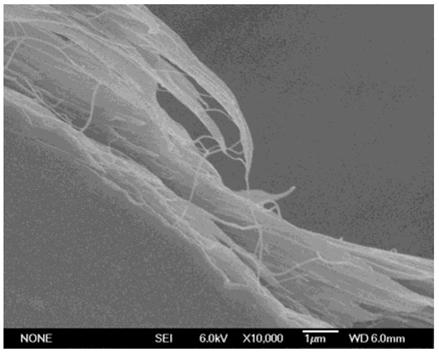

[0029] (1) Single-walled carbon nanotube films are prepared by chemical vapor deposition, with diameters ranging from tens to hundreds of microns;

[0030] (2) the single-walled carbon nanotube film prepared in step (1) is collected with a rotating drum, and the drum is immersed in the composite solution while collecting the single-walled carbon nanotube film, and the single-walled carbon nanotube film and the composite solution Layer-by-layer stacking makes the single-wall carbon nanotube film form a composite film, and with the rotation of the drum, the single-wall carbon nanotube composite film is obtained;

[0031] (3) in the step (2), the drum wheel with single-wall carbon nanotube composite film is taken out from the composite solution and then rotated, and the drum wheel with single-wall carbon nanotube composite film rotates und...

Embodiment 1

[0039]The single-walled carbon nanotube film prepared by chemical vapor deposition is collected by a rotating drum at the outlet of the quartz tube, and the rotating drum is immersed in polyvinyl alcohol / carbon nanotube while collecting the single-walled carbon nanotube. In the composite solution of dimethyl sulfoxide / absolute ethanol, single-wall carbon nanotubes and polyvinyl alcohol / dimethyl sulfoxide / absolute ethanol composite solution are stacked layer by layer to form single-wall carbon nanotubes / polyvinyl alcohol / Dimethyl sulfoxide / absolute ethanol composite film, and single-walled carbon nanotube / polyvinyl alcohol / dimethyl sulfoxide / absolute ethanol composite film were superimposed and collected for 10 minutes.

Embodiment 2

[0041] The single-walled carbon nanotube film prepared by chemical vapor deposition is collected by a rotating drum at the outlet of the quartz tube, and the rotating drum is immersed in polyvinyl alcohol / carbon nanotube while collecting the single-walled carbon nanotube. In the composite solution of dimethyl sulfoxide / absolute ethanol, single-wall carbon nanotubes and polyvinyl alcohol / dimethyl sulfoxide / absolute ethanol composite solution are stacked layer by layer to form single-wall carbon nanotubes / polyvinyl alcohol / Dimethyl sulfoxide / absolute ethanol composite film, and single-walled carbon nanotube / polyvinyl alcohol / dimethyl sulfoxide / absolute ethanol composite film were superimposed and collected for 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com