High-precision battery labeling structure

A high-precision, battery-powered technology, applied to labeling machines, labels, packaging, etc., can solve problems such as complex operations, low production efficiency, and labor costs, and achieve improved recognition effects, labeling efficiency, and labeling accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred examples of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred examples described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

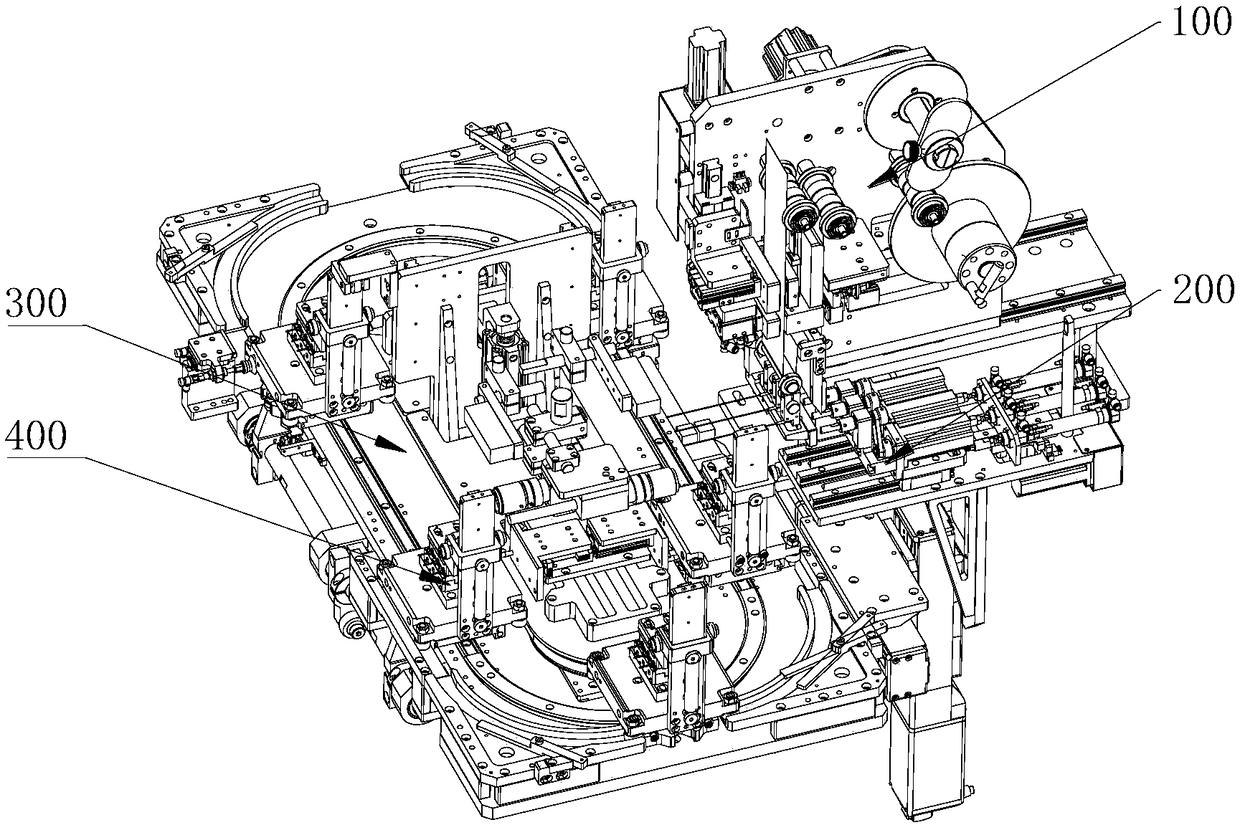

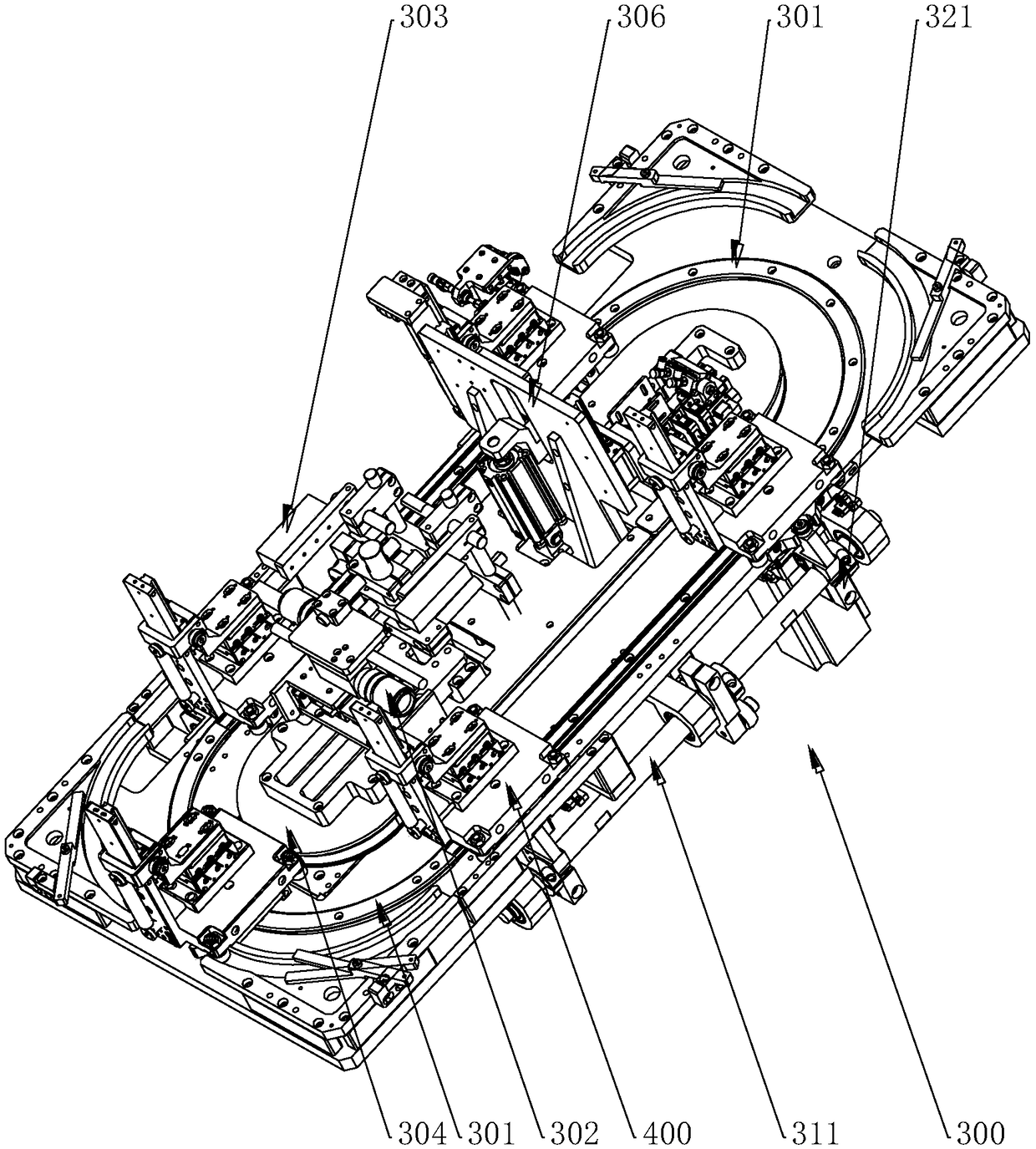

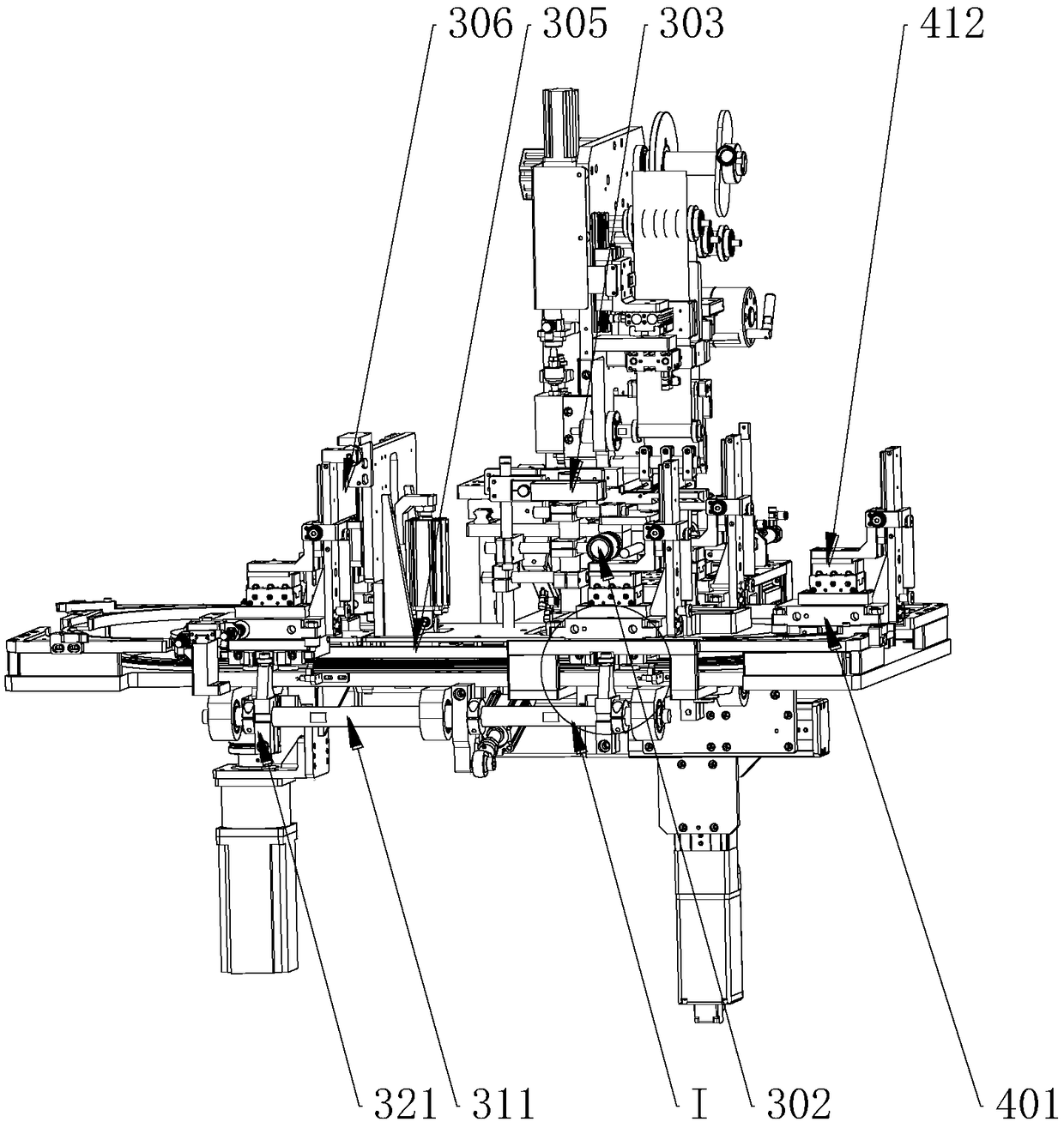

[0034] Such as Figures 1 to 13 As shown, the high-precision battery labeling structure includes an unwinding assembly 100 , a labeling assembly 200 , a track assembly 300 and an attachment receiving table assembly 400 .

[0035] A pair of unwinding assemblies 100 and a pair of labeling assemblies 200 are respectively arranged symmetrically on both sides of the track assembly 300 , and several sticking and receiving platform assemblies 400 are arranged on the track assembly 300 .

[0036] The unwinding assembly 100 transports the labeled roll film to the labeling assembly 200. The labeling assembly 200 includes a suction rod 201 and a guide rail 202. The suction rod 201 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com