Off-road vehicle with rear engine and using method thereof

An off-road vehicle and engine technology, which is applied in the field of off-road vehicles, can solve problems such as difficult engine noise and the impact on passenger comfort in the vehicle, and achieve the effects of reasonable mass center of gravity, improved space utilization, and spacious cabin space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

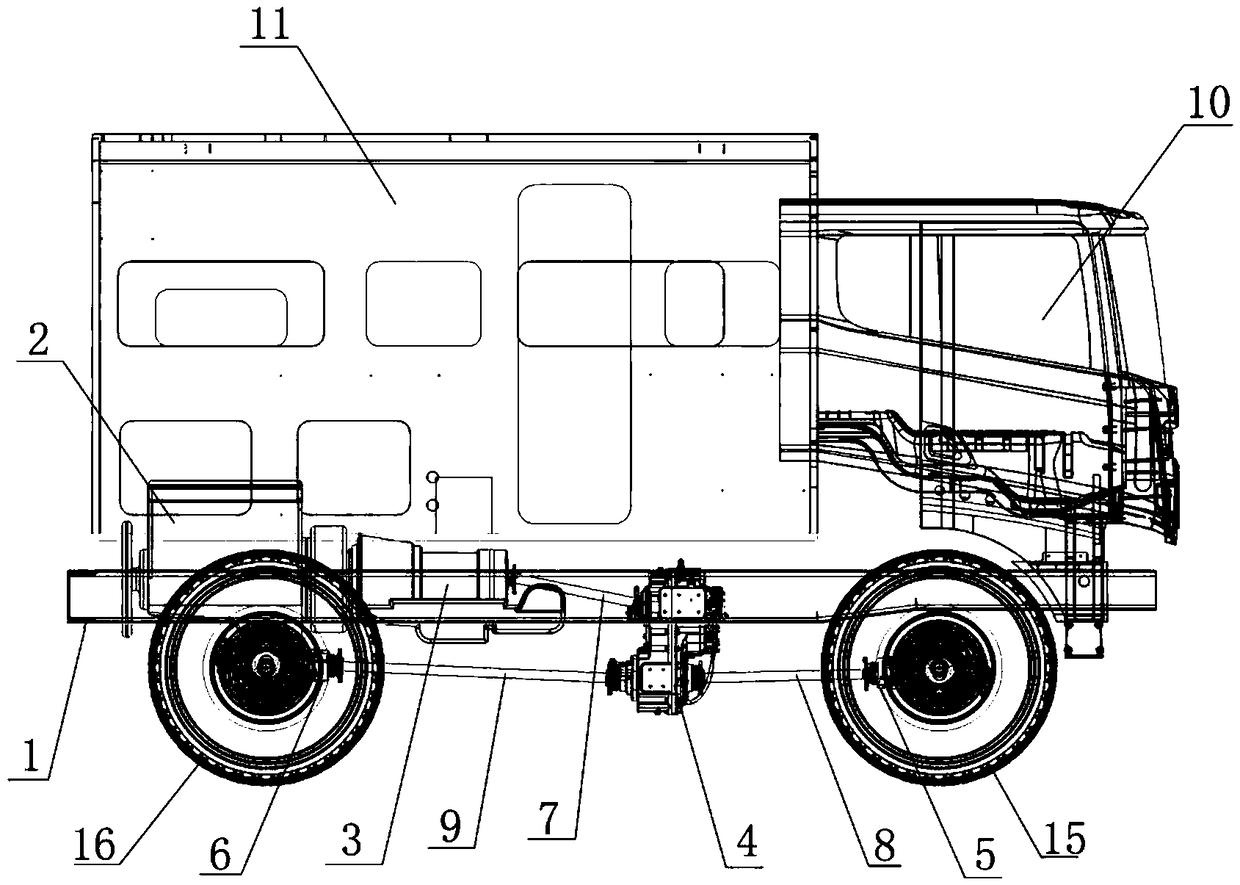

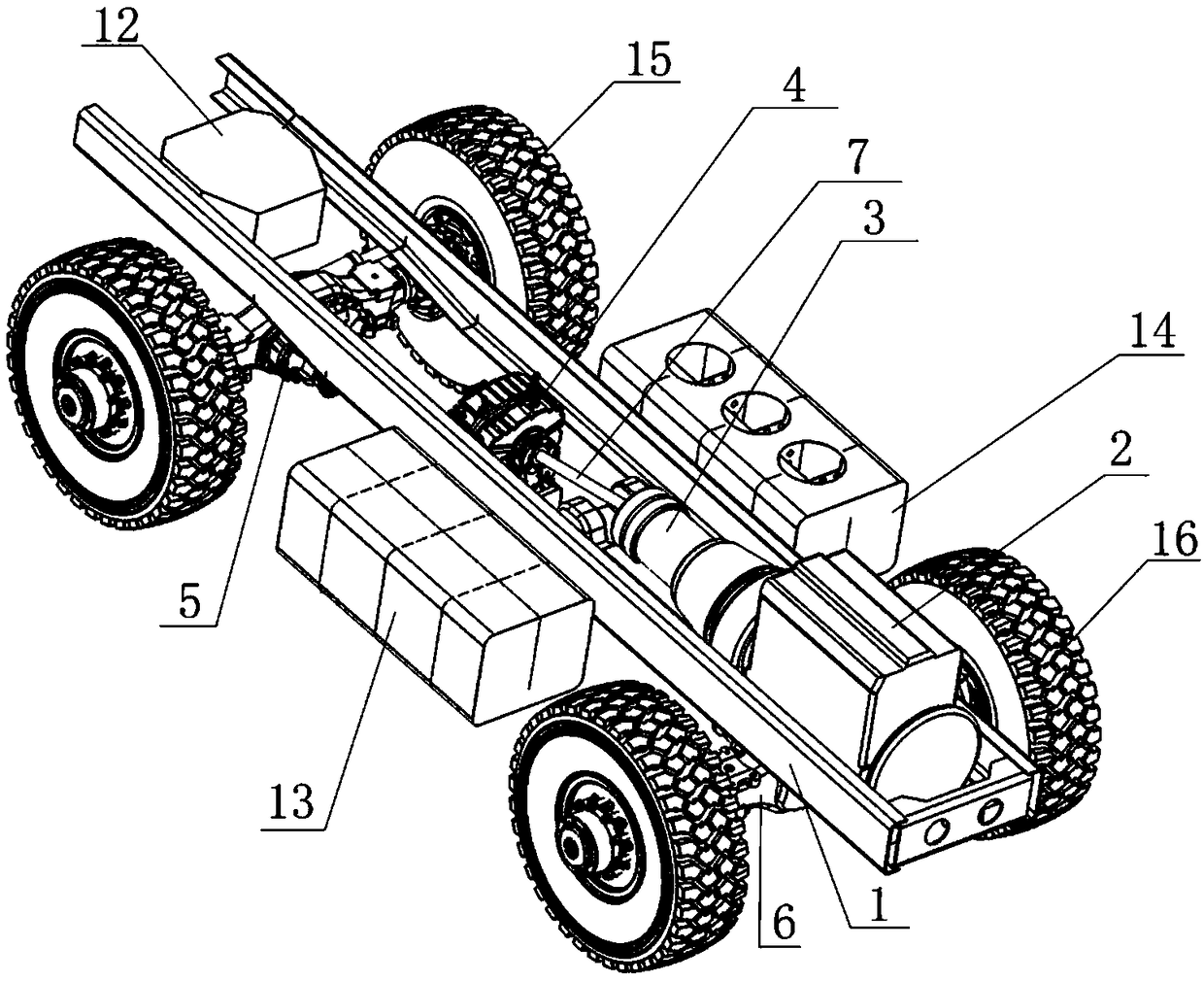

[0029] Such as Figure 1-2 An off-road vehicle with a rear engine is shown. The off-road vehicle is an off-road touring vehicle or an off-road passenger vehicle, which includes a chassis 1, an engine 2, a transmission 3, a transfer case 4, a front axle 5 and a rear axle 6. The bottom end of the engine 2 is installed at the rear of the chassis 1, the front end of the engine 2 is provided with a gearbox 3, the engine 2 is in transmission connection with the gearbox 3, and the front end of the gearbox 3 is connected to the transfer via a first drive shaft 7. The input end of the transfer case 4 is connected, the first output end of the transfer case 4 is connected to the front axle 5 through the second transmission shaft 8, and the second output end of the transfer case 4 is connected to the rear axle through the third transmission shaft 9 6Connect.

[0030] The gearbox can produce different gear ratios between the engine and the wheels during the driving of the car. Gear shifting ...

Embodiment 2

[0039] In this embodiment, except that the technical solution is different from embodiment 1, other technical features are the same as that of embodiment 1:

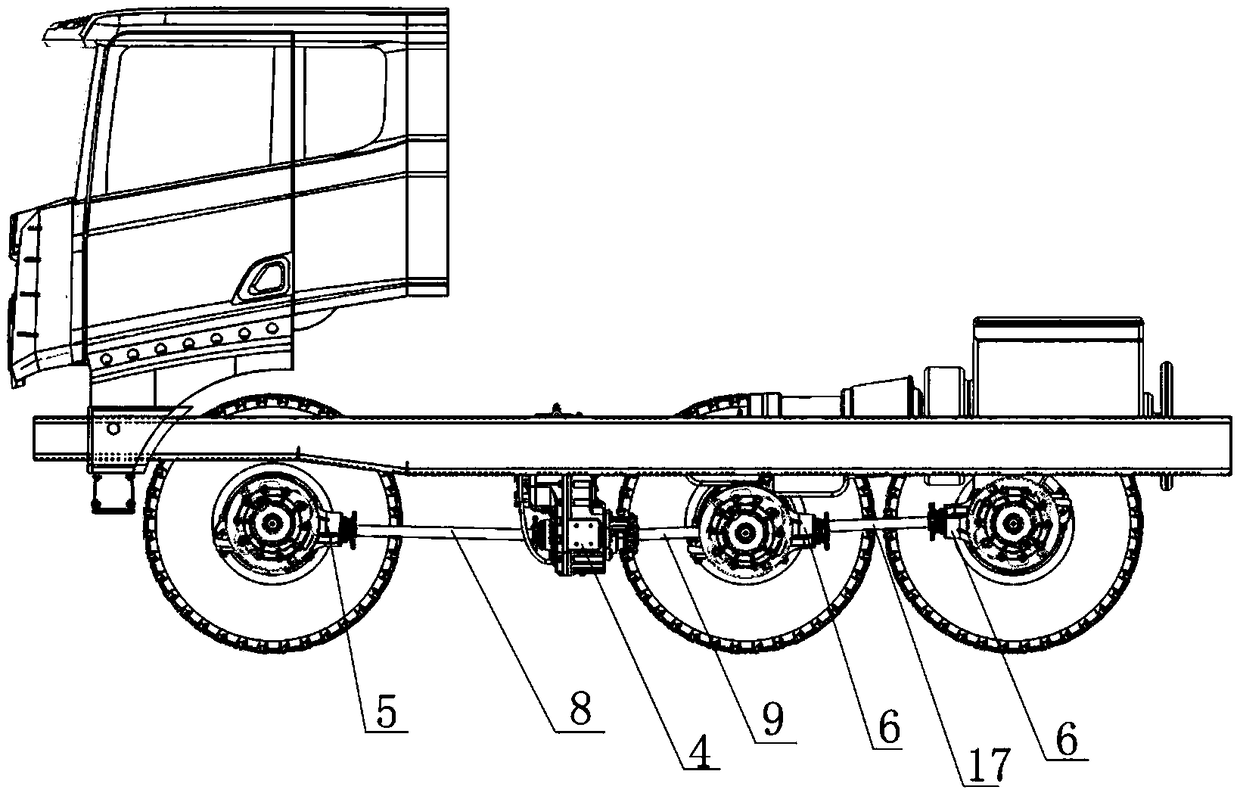

[0040] Such as image 3 As shown, the off-road vehicle includes a front axle 5 and two rear axles 6. A front tire is installed at both ends of the front axle 5; a rear tire is installed at both ends of each rear axle 6 ; Between the two rear axles 6 through the fourth transmission shaft 17 transmission connection. Through the above technical solution, the engine is placed at the rear, and the six tires are driven by the transfer case 4. The transfer case 4 transmits power to the rear axle 6 close to the transfer case 4 through the third transmission shaft 9 and is close to the transfer case 4. The rear axle 6 of the power case 4 transmits power to the other rear axle 6 through the fourth transmission shaft 17, thereby realizing the driving of the rear tires.

Embodiment 3

[0042] In this embodiment, except that the technical solution is different from embodiment 1, other technical features are the same as that of embodiment 1:

[0043] The off-road vehicle includes two front axles 5 and two rear axles 6, each of which is equipped with a front tire at both ends; each of the rear axles 6 is equipped with a rear tire at both ends. The two front axles 5 are connected by a fifth drive shaft; the two rear axles 6 are connected by a sixth drive shaft.

[0044] Through the above technical solution, the engine is placed at the rear, and the eight tires are driven by the transfer case 4. The transfer case 4 transmits power to the front axle 5 close to the transfer case 4 through the second transmission shaft, and is close to the transfer case 4. The front axle 5 of the transmission case 4 transmits power to the other front axle 5 through the fifth transmission shaft transmission, thereby realizing the driving of the front tires; the transmission case 4 transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com