Railway loading-unloading platform cart

A platform vehicle and railway technology, applied in the loading and unloading of railway vehicles, railway car body parts, transportation and packaging, etc., can solve the problems of limited platform width, high labor intensity, narrow size, etc., to achieve safe and reliable loading and unloading, and ensure smoothness The effect of safety and convenient unloading of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

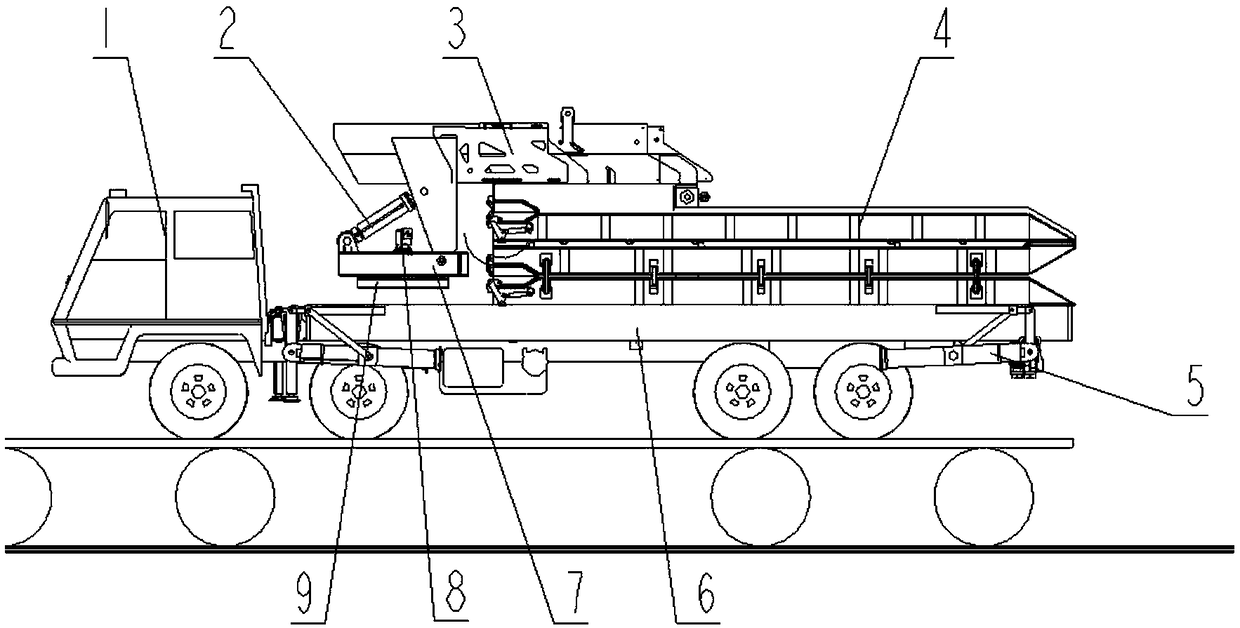

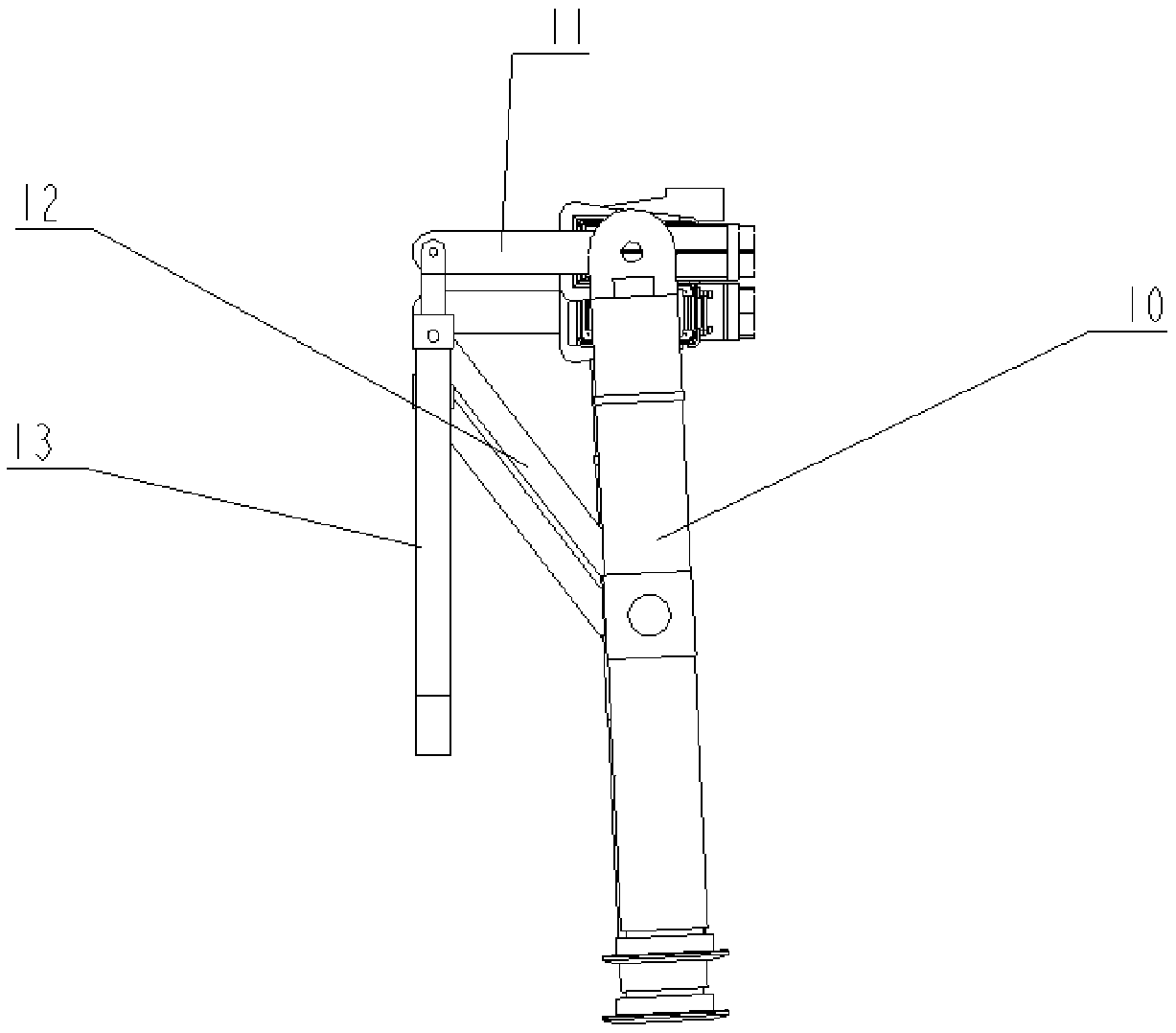

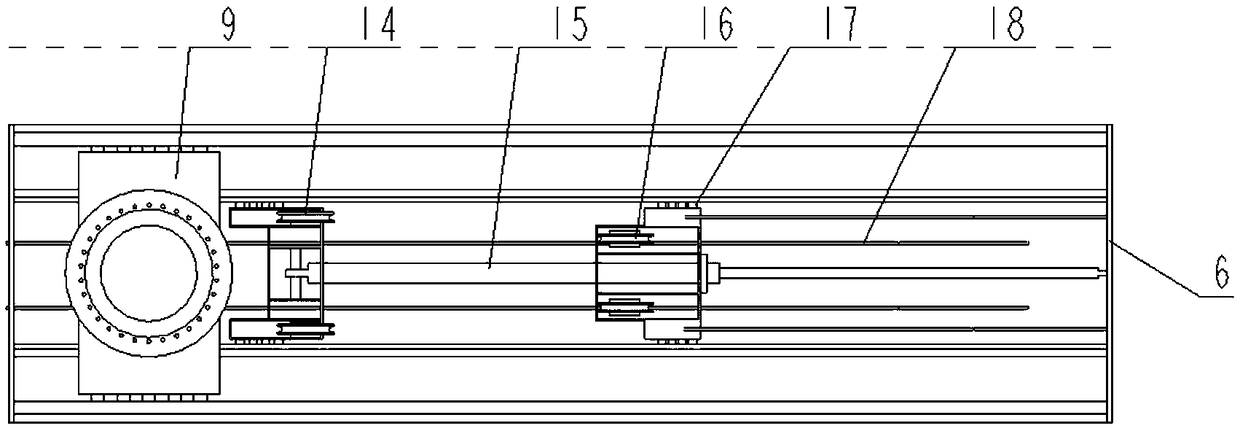

[0039] Such as Figure 1 to Figure 7 As shown, a railway loading and unloading platform vehicle includes a chassis 1, a luffing cylinder 2, a telescopic arm 3, a platform 4, legs 5, a subframe 6, a slewing bearing 7, a slewing motor 8, a moving trolley 9, a vertical support Leg 10, first connecting rod 11, second connecting rod 12, oil cylinder 13, first pulley 14, telescopic oil cylinder 15, second pulley 16, sliding support 17, wire rope 18, third sub-board 19, second sub-board 20 , the first sub-board 21, the main board 22, the platform connection pin seat 23;

[0040] In some embodiments, such as figure 1 As shown, a sub-frame 6 is installed on the chassis 1, a moving trolley 9 is movably arranged on the sub-frame 6, a turning mechanism is arranged on the moving trolley 9, and the telescopic arm 3 passes through the luffing cylinder 2 Connected with the turning mechanism of the mobile trolley 9, the platform 4 is detachably connected with the telescopic arm 3;

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com