Gantry type truss manipulator

A manipulator and gantry-type technology, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of unsatisfactory automatic production, inability to guarantee operation stability and precision, and achieve the goal of saving manpower, ensuring stability and improving load capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

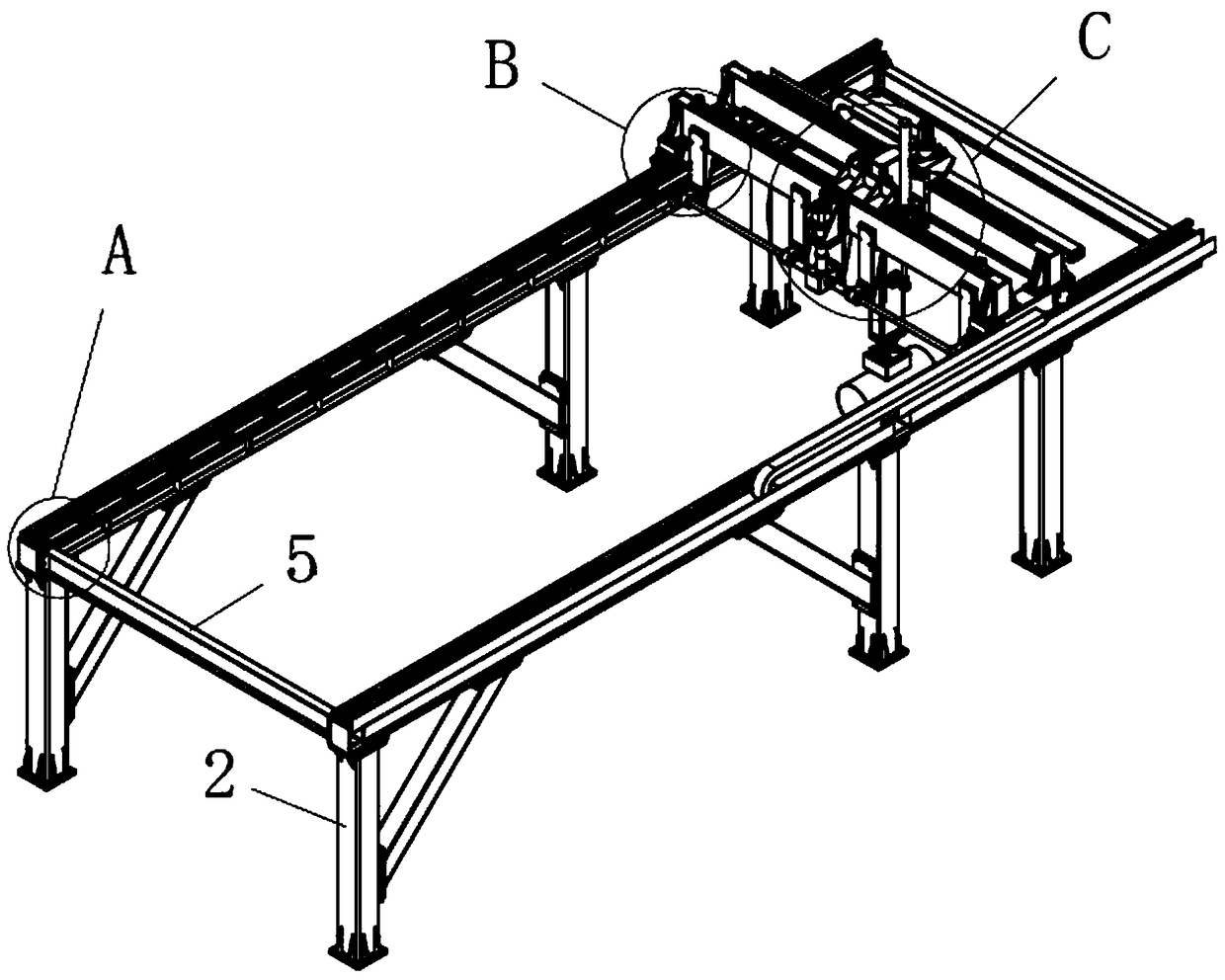

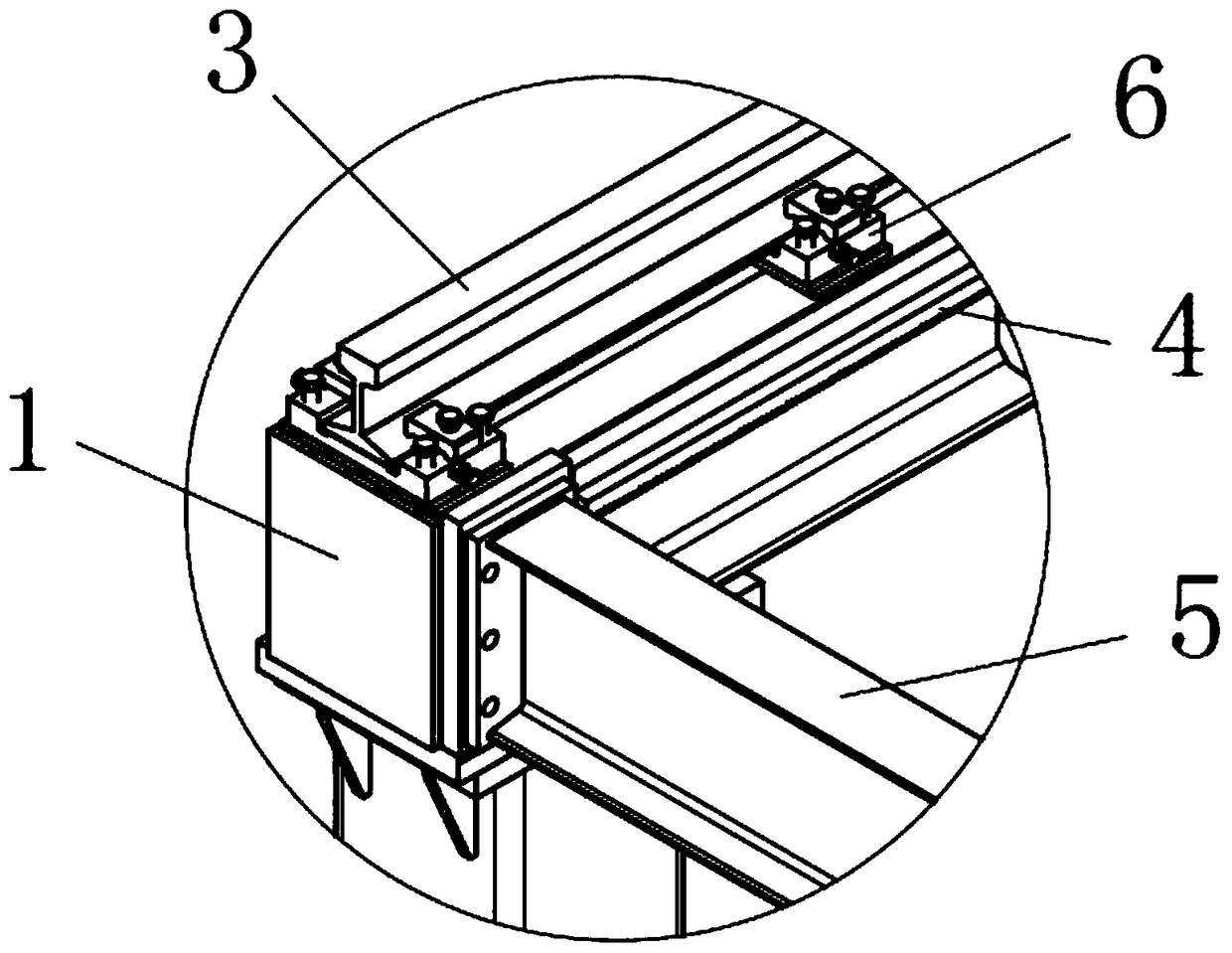

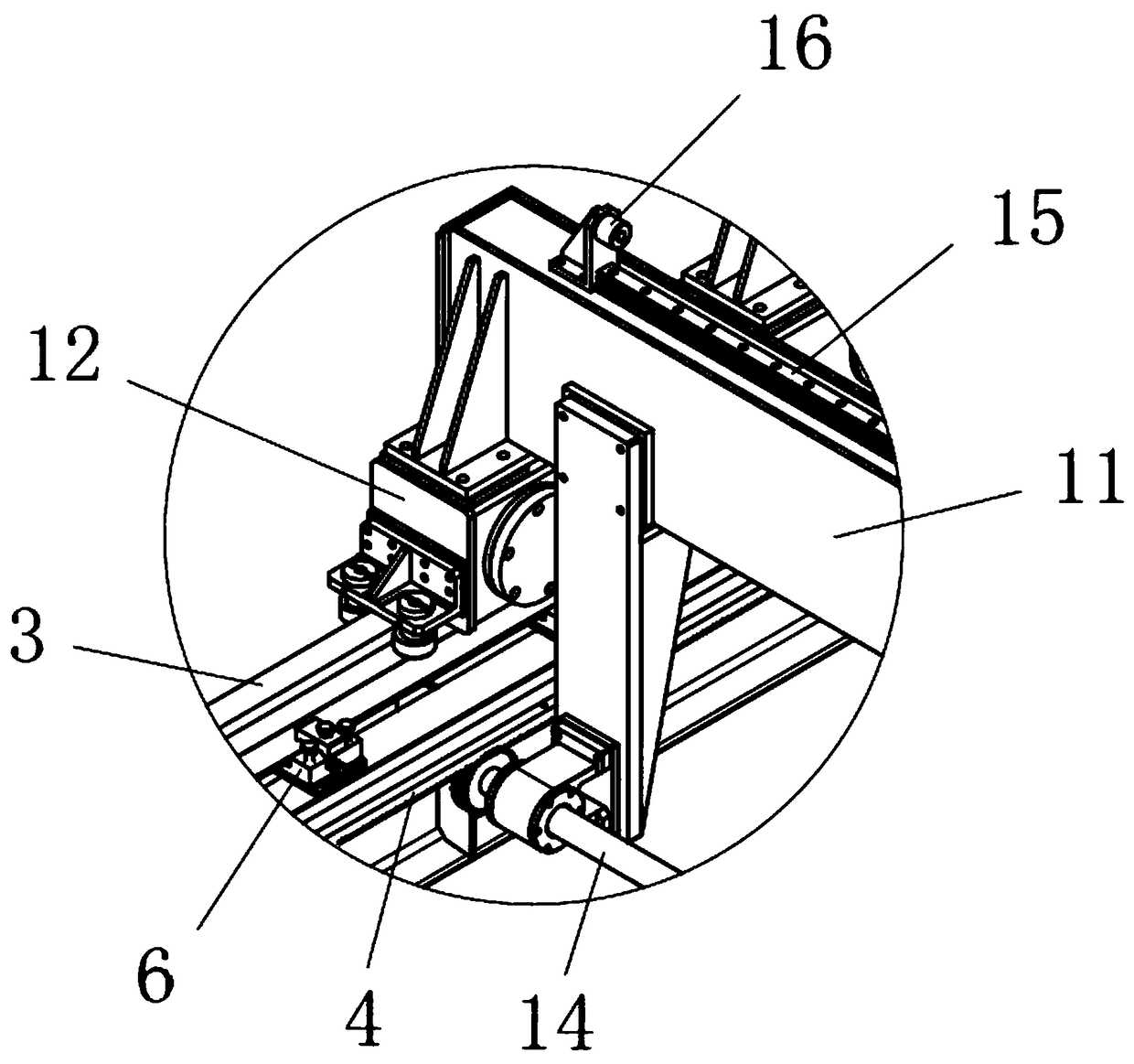

[0019] like Figure 1-5 As shown in the figure, a gantry type truss manipulator according to the present invention includes a gantry support, a forward movement mechanism, a transverse movement mechanism and a manipulator assembly; the gantry support includes two parallel forward movement bearing beams 1, each forward movement The lower side of the bearing beam 1 is provided with a plurality of legs 2, and a reinforcing beam 5 is arranged between the two forward-moving bearing beams 1, and the reinforcing beam 5 is arranged at the front and rear ends of the forward-moving bearing beam 1 to improve the stability of the overall structure. Each forward-moving bearing beam 1 is provided with a forward-moving guide rail 3, a forward-moving rack 4 and a plurality of slide rail pressing seats 6 arranged along the length direction of the forwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com