Hexagonal socket flange bolt machining device

A flange bolt and processing device technology, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low production efficiency, numerous production equipment, and high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

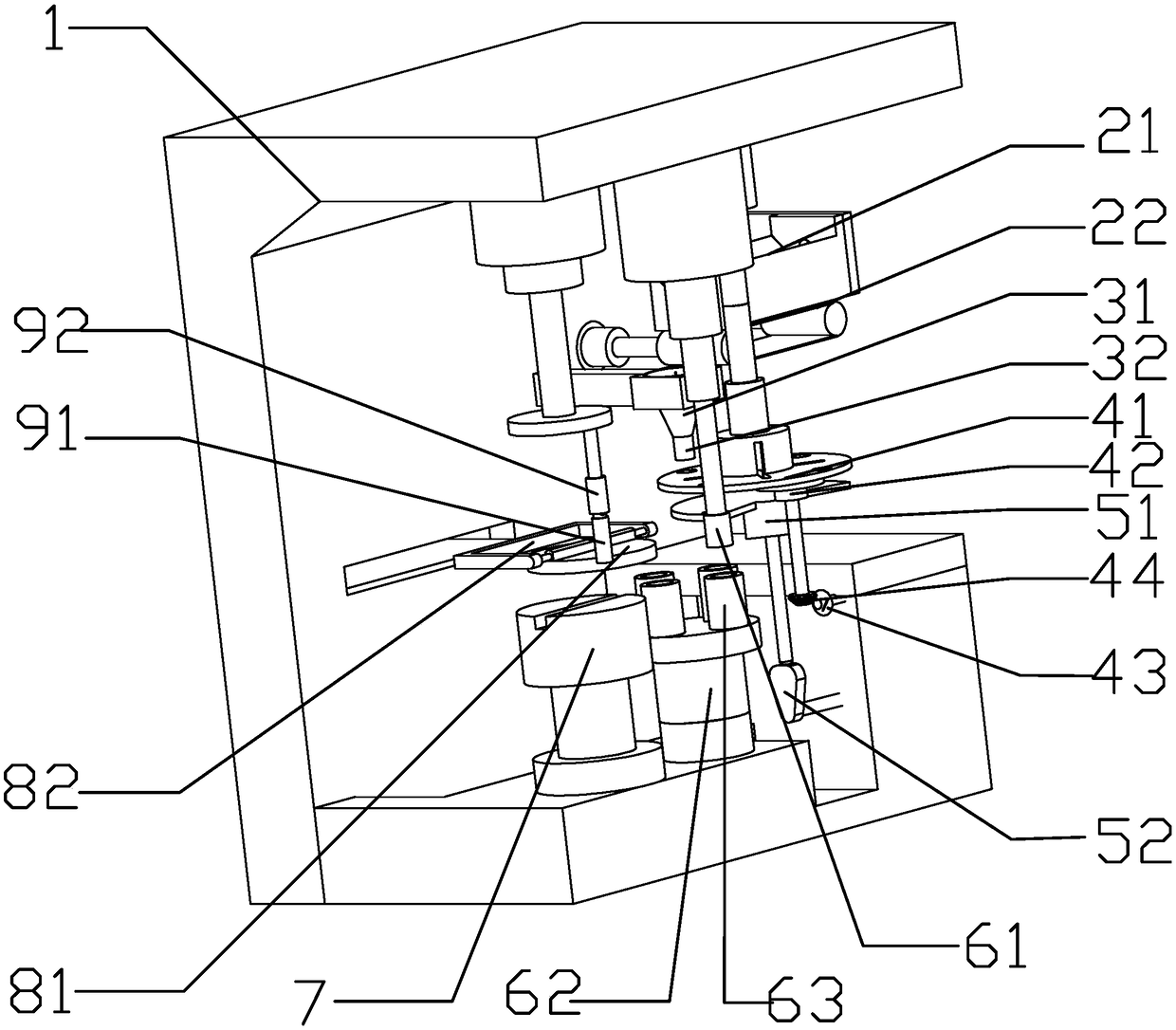

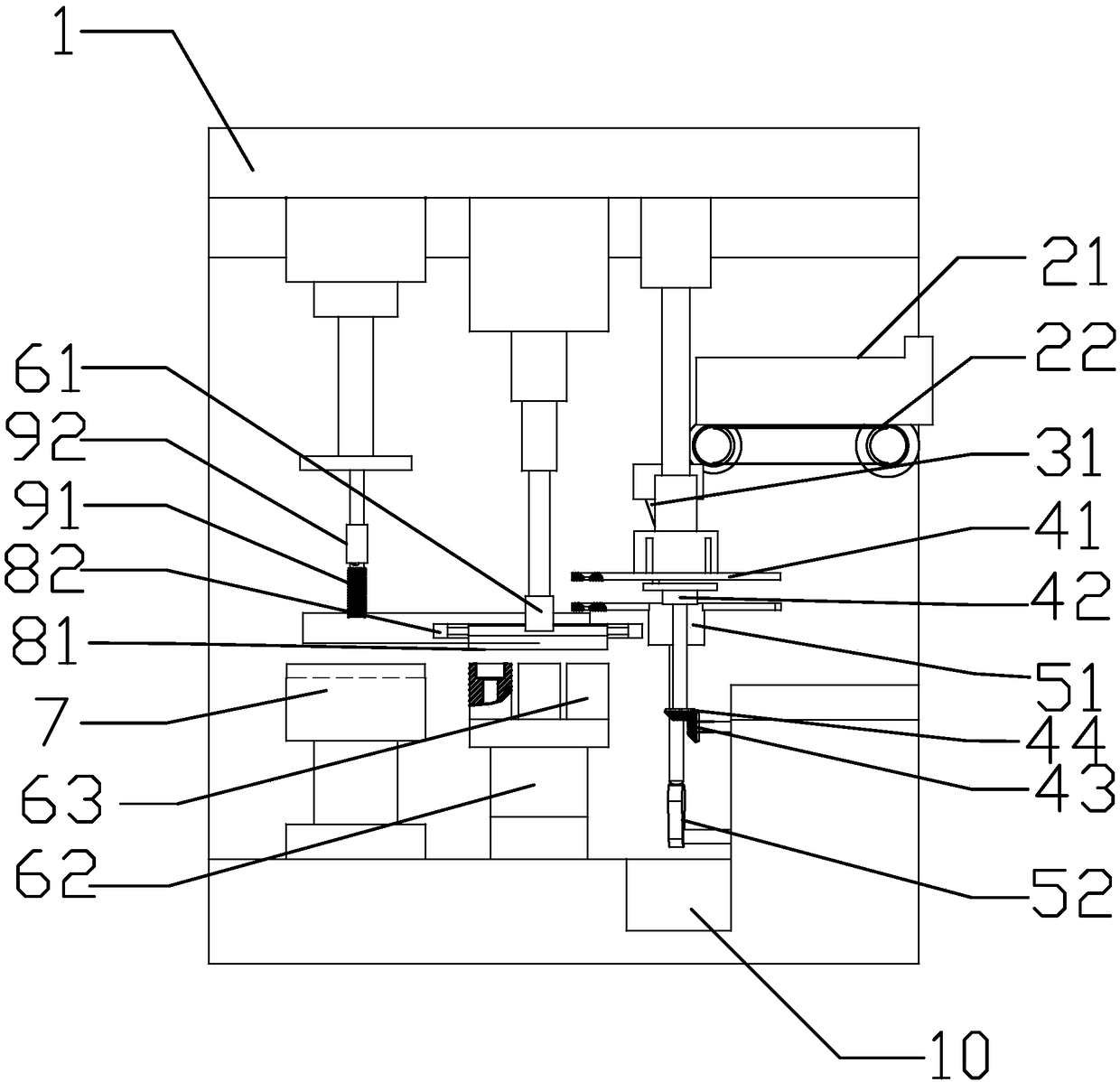

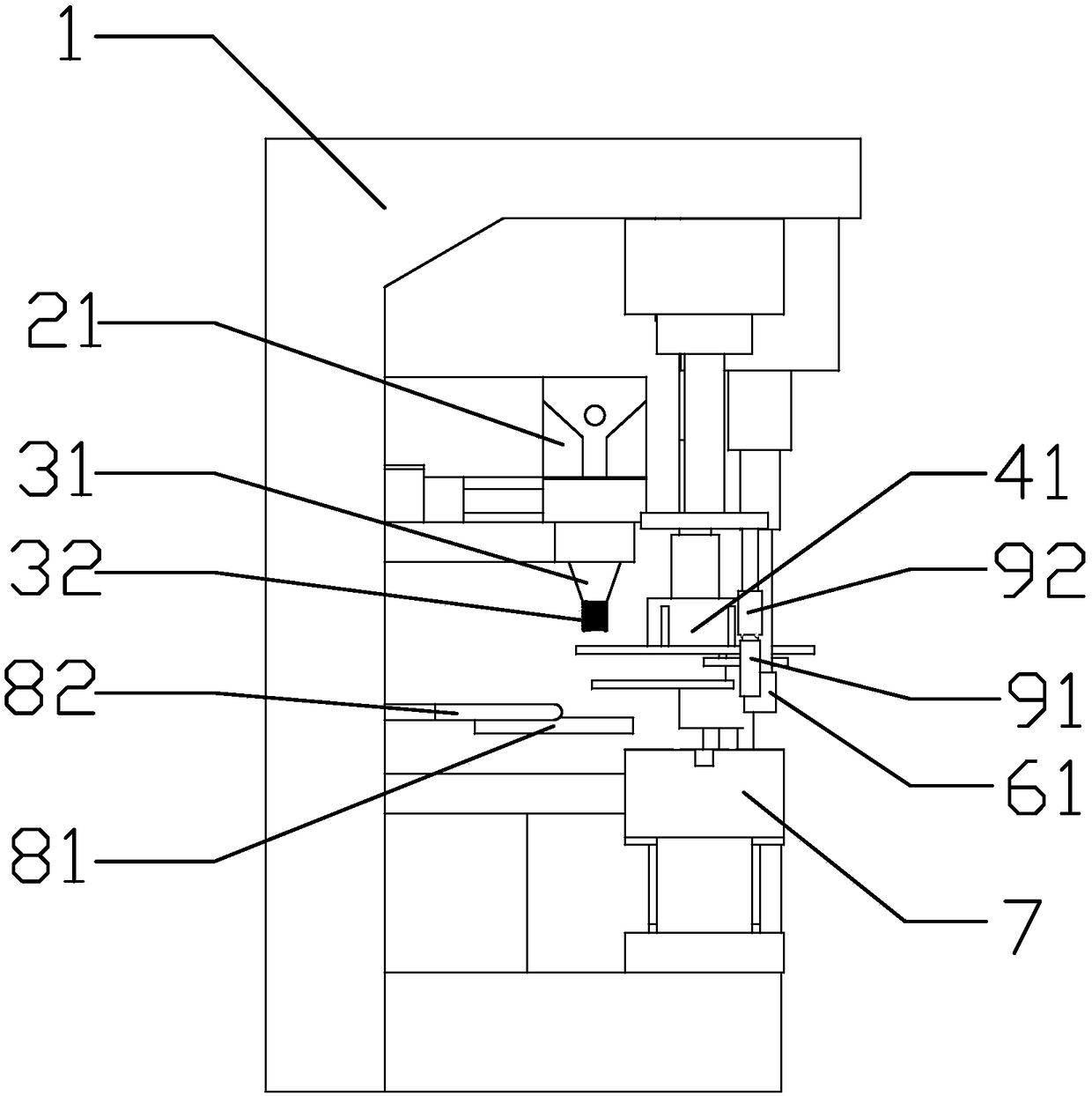

[0031] Example 1 as Figure 1-14 Shown: a kind of hexagon socket flange bolt processing device among the present invention, comprises frame 1 and base, is also provided with mold mechanism, thread rolling mechanism, output mechanism on frame 1, and mold mechanism is on the left side of cam mechanism, The thread rolling mechanism is on the left side of the mold mechanism, the output end of the output mechanism is connected to the input end of the sheave mechanism and the cam mechanism, a heating mechanism is provided on the frame 1, and a sheave mechanism and a cam mechanism are arranged below the heating mechanism. The heating mechanism includes a conical bucket 31. A heating coil 32 is arranged inside the conical bucket 31. The sheave mechanism includes a runner 42. And it is used for the first through hole through which the cylindrical blank 12 passes, and the position of the first through hole corresponds to the radial groove in the groove wheel 41; the cam mechanism includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com