Automatic seal machine

A stamping machine, automatic technology, used in printing, stamping and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below.

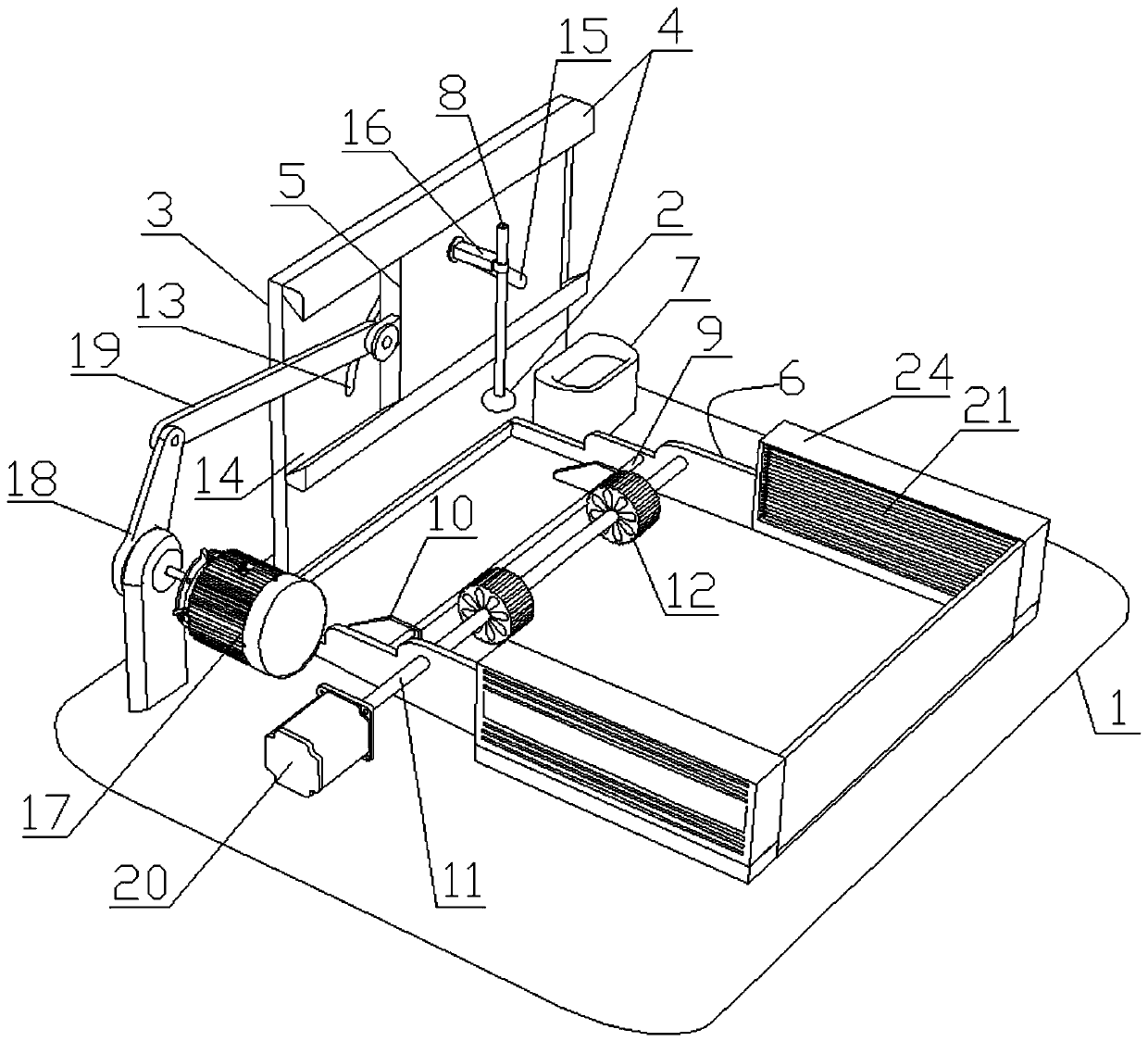

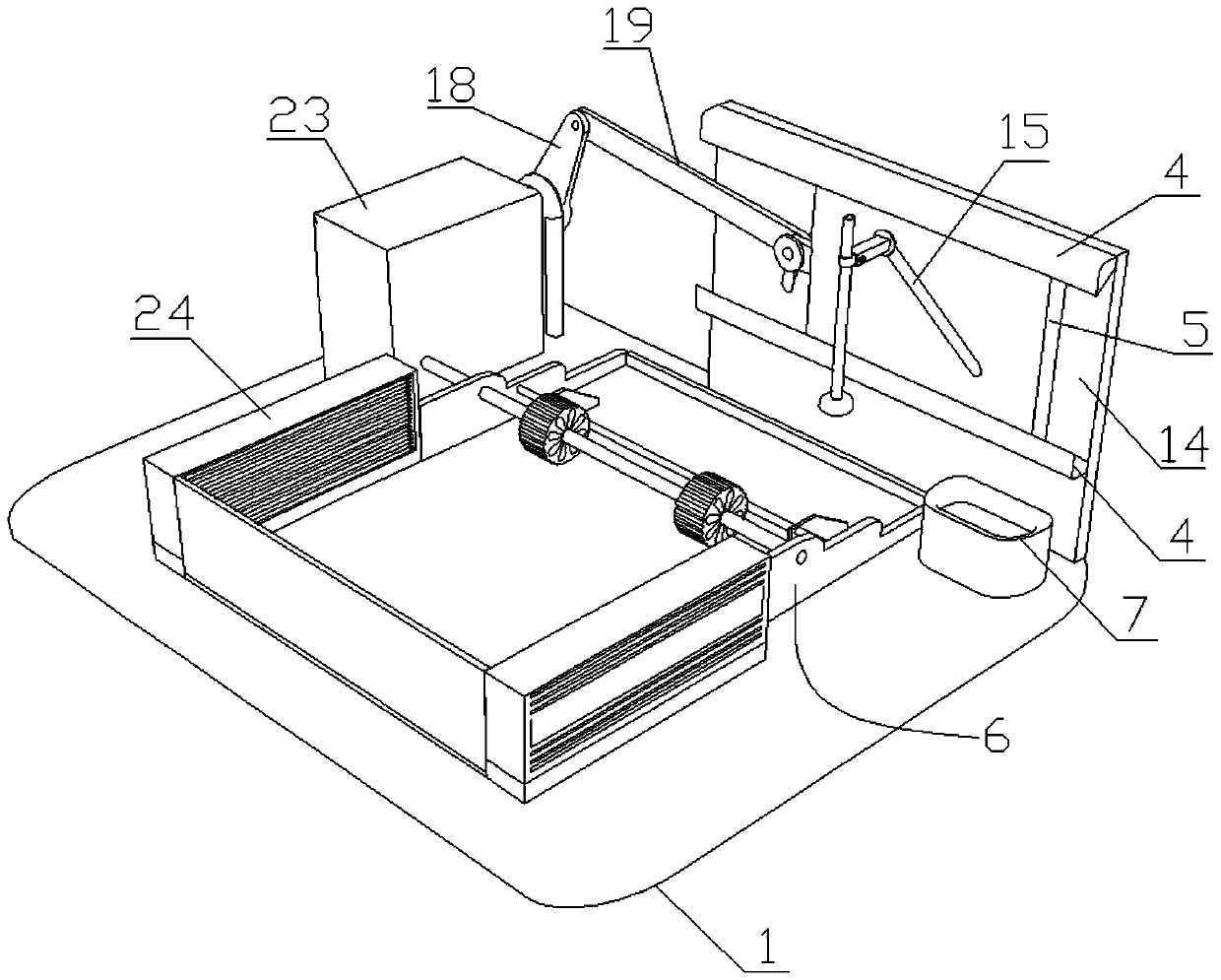

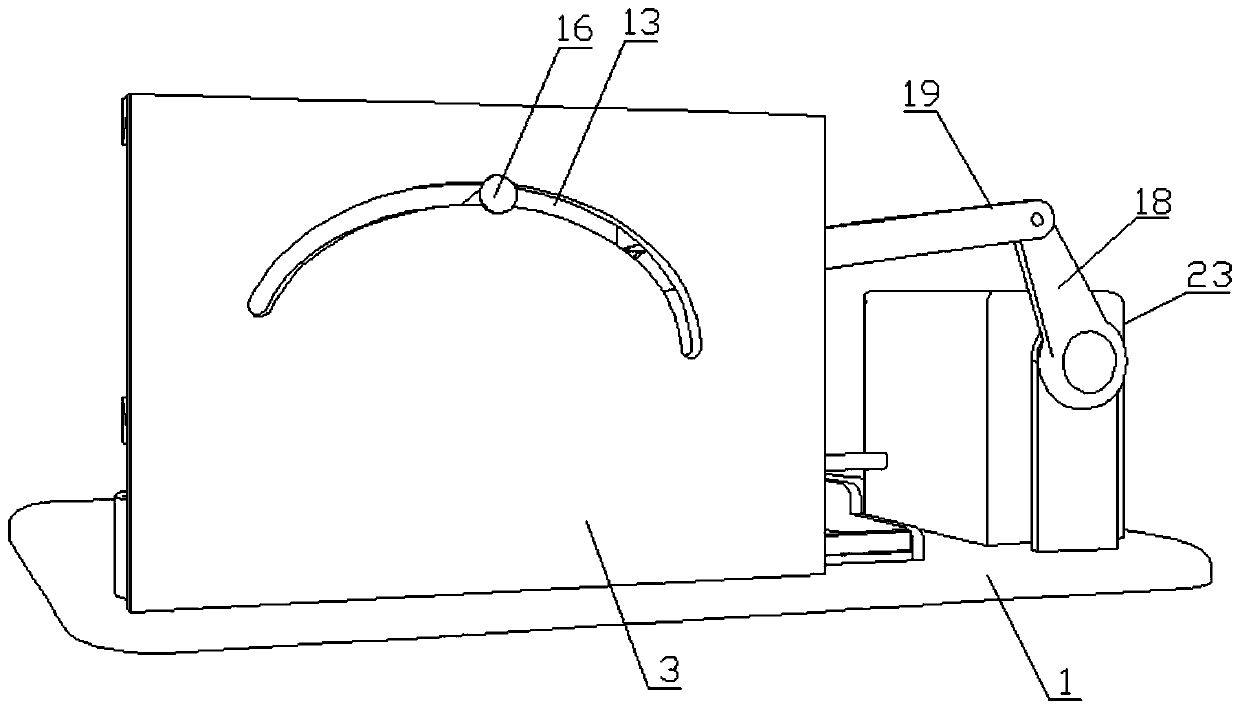

[0028] Such as Figure 1 to Figure 4 As shown, an automatic stamping machine includes a support base plate 1, a seal 2, a support vertical plate 3, a pair of guide rails 4, a slide plate 5, a load frame 6, an ink pad box 7, a connecting rod 8, a first drive motor 17, Guide rod 9, a pair of paper baffles 10, a transmission shaft 11, a pair of pickup rollers 12 and two hot air units;

[0029] The support vertical plate 3 is fixedly connected to the front end of the support base plate 1, and the middle part of the support vertical plate 3 is provided with an arc-shaped through groove 13. The two arc bottoms are set flush with each other;

[0030] A pair of guide rails 4 are longitudinally spaced apart on the upper and lower sides of the arc-shaped through groove 13, and are fixedly connected with the support vertical plate 3, forming a transverse chute 14 between the pair of guide rails 4;

[0031] The size of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com