Welding system and method for battery sealing nails

A welding system and welding method technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of poor consistency of penetration depth and penetration width, uneven surface of welding seam, large size of welding equipment, etc. The effect of high melting width consistency, smooth welding surface and fast welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

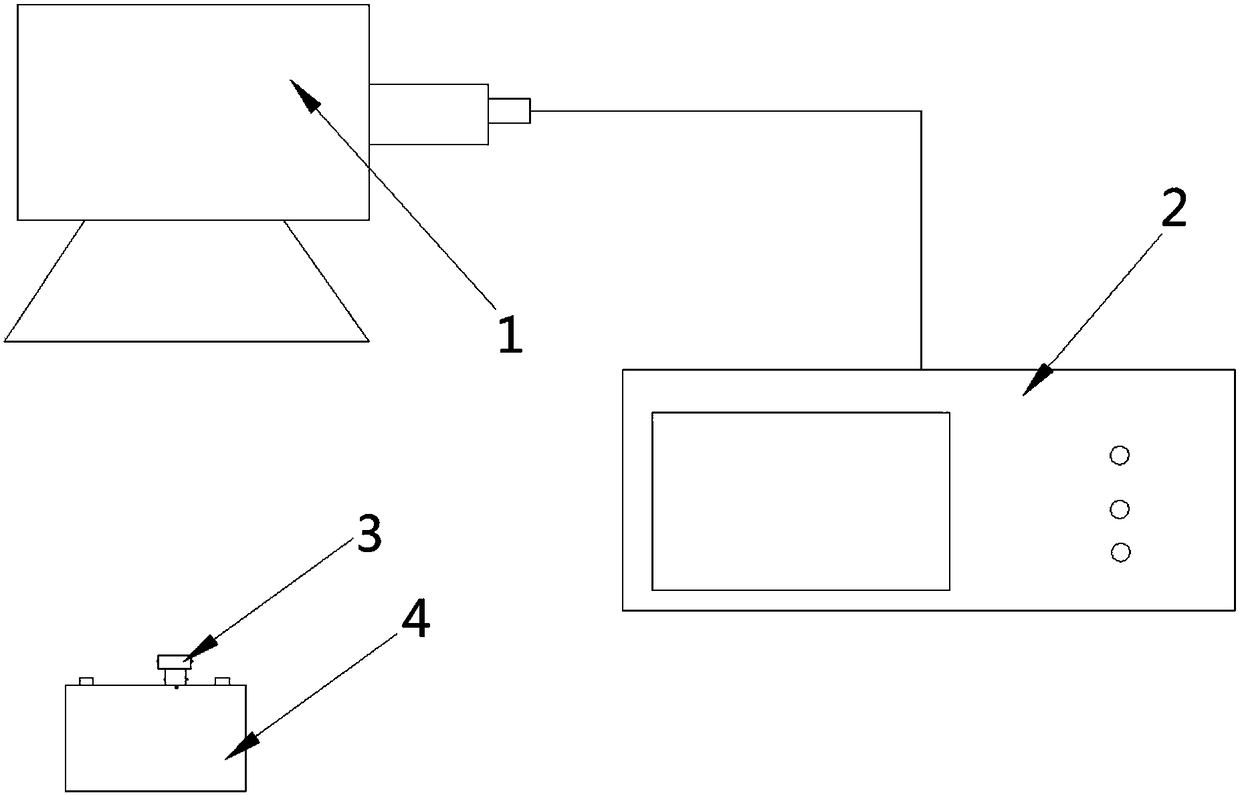

[0030] The invention provides a welding system for battery sealing nails, see figure 1 , the system includes a vibrating mirror 1, a fiber laser 2 and an air blowing device 3, wherein the vibrating mirror 1 is arranged directly above the blowing device 3, and is connected to the fiber laser 2 through an optical fiber, The fiber laser 2 is used to emit laser light of a certain power, the vibrating mirror 1 is used to receive the laser light emitted by the fiber laser 2, and output the laser light according to the preset welding trajectory for laser welding, and the blowing device 3 is used to provide a relatively sealed Welding environment.

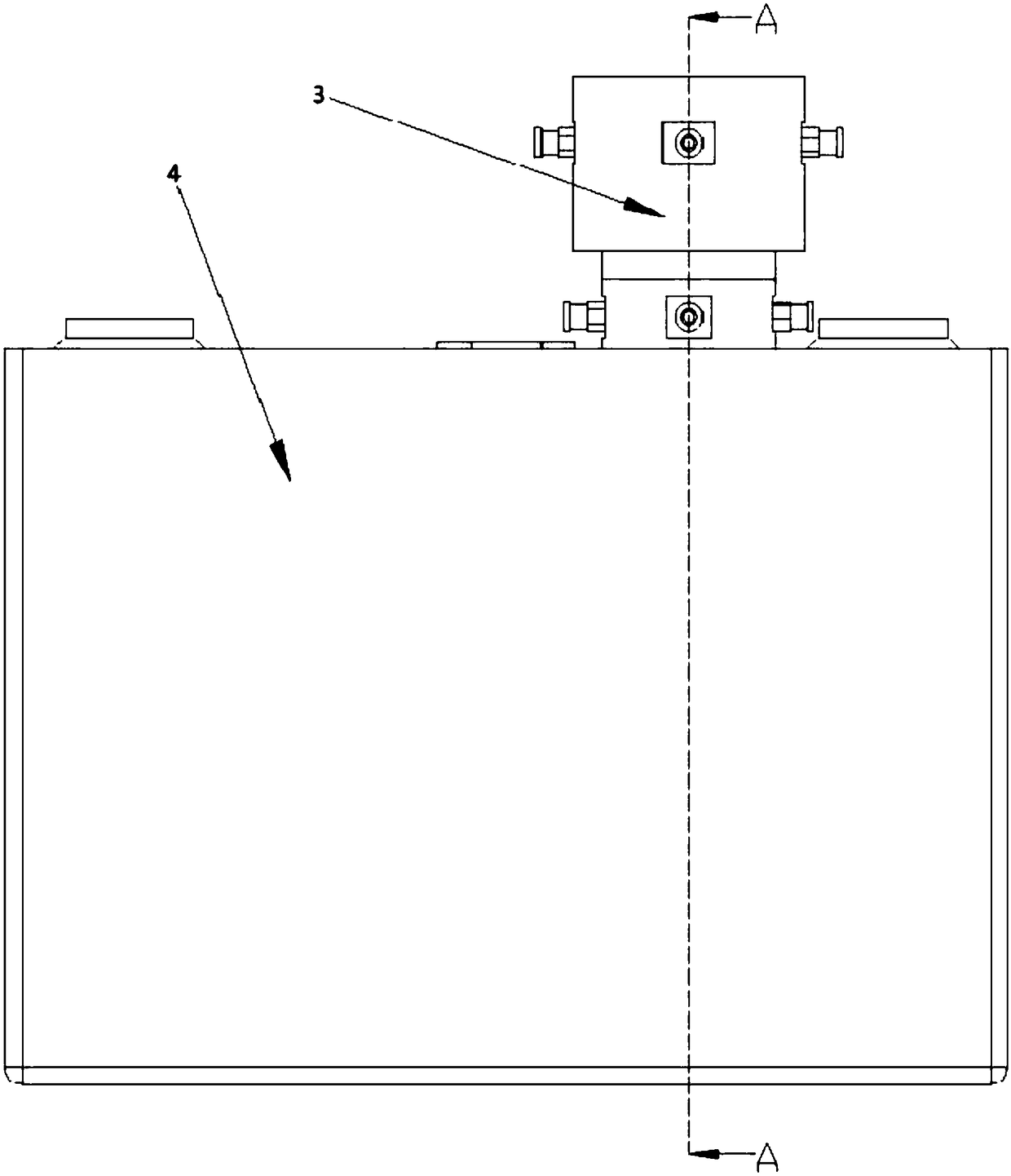

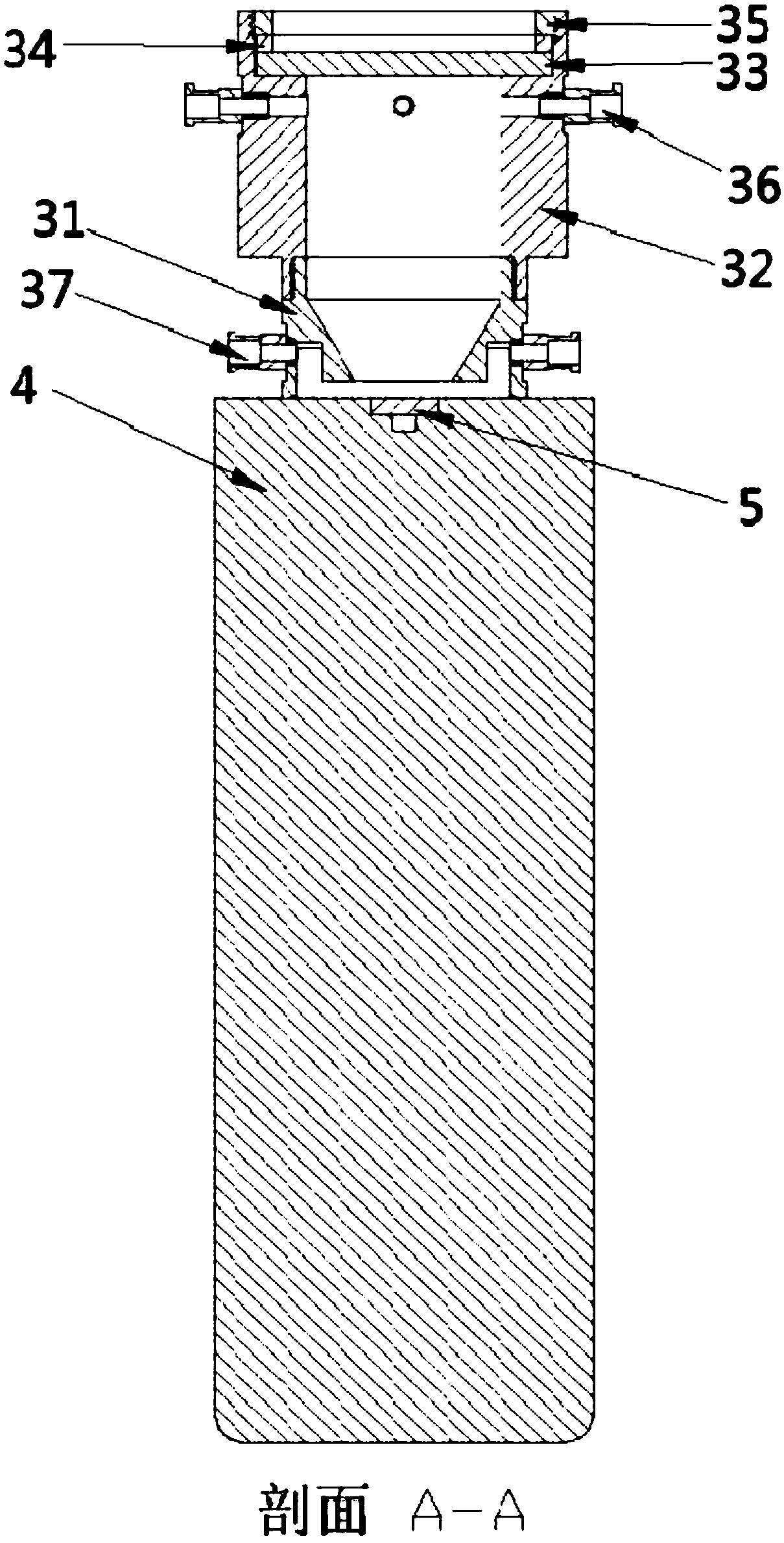

[0031] refer to figure 2 , the figure is a front view of the connection structure between the air blowing device 3 and the battery 4. In the embodiment of the present invention, the lower part of the air blowing device 3 is closely attached to the battery 4, so that a sealed air blowing environment can be formed , prevent external air f...

Embodiment 2

[0041] The present invention also provides a welding method applied to the battery sealing nail welding system described in Embodiment 1, see Figure 4 , the welding method comprises the steps of:

[0042] S1: setting the vibrating mirror directly above the battery, making the vibrating mirror coaxial with the sealing nail on the battery, and adjusting the height between the vibrating mirror and the surface of the weld;

[0043] In the embodiment of the present invention, the sealing nail 5 of the battery 4 is welded by combining the vibrating mirror 1 with the fiber laser 2. The emitted laser coincides with the weld seam to be welded, thus making the welding more accurate;

[0044] In the embodiment of the present invention, by designing the welding track of the galvanometer 1 during welding on the galvanometer control software, the welding operation of the galvanometer 1 includes three sections of welding tracks connected in sequence. In this embodiment, the first section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com