Washing and drying device for honeysuckles

A drying device, honeysuckle technology, applied in the direction of drying gas arrangement, heating device, drying room/container, etc., can solve the problems of uneven heating, low work efficiency, poor cleaning quality, etc., to maintain taste and nutrition, and improve work efficiency , The effect of improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

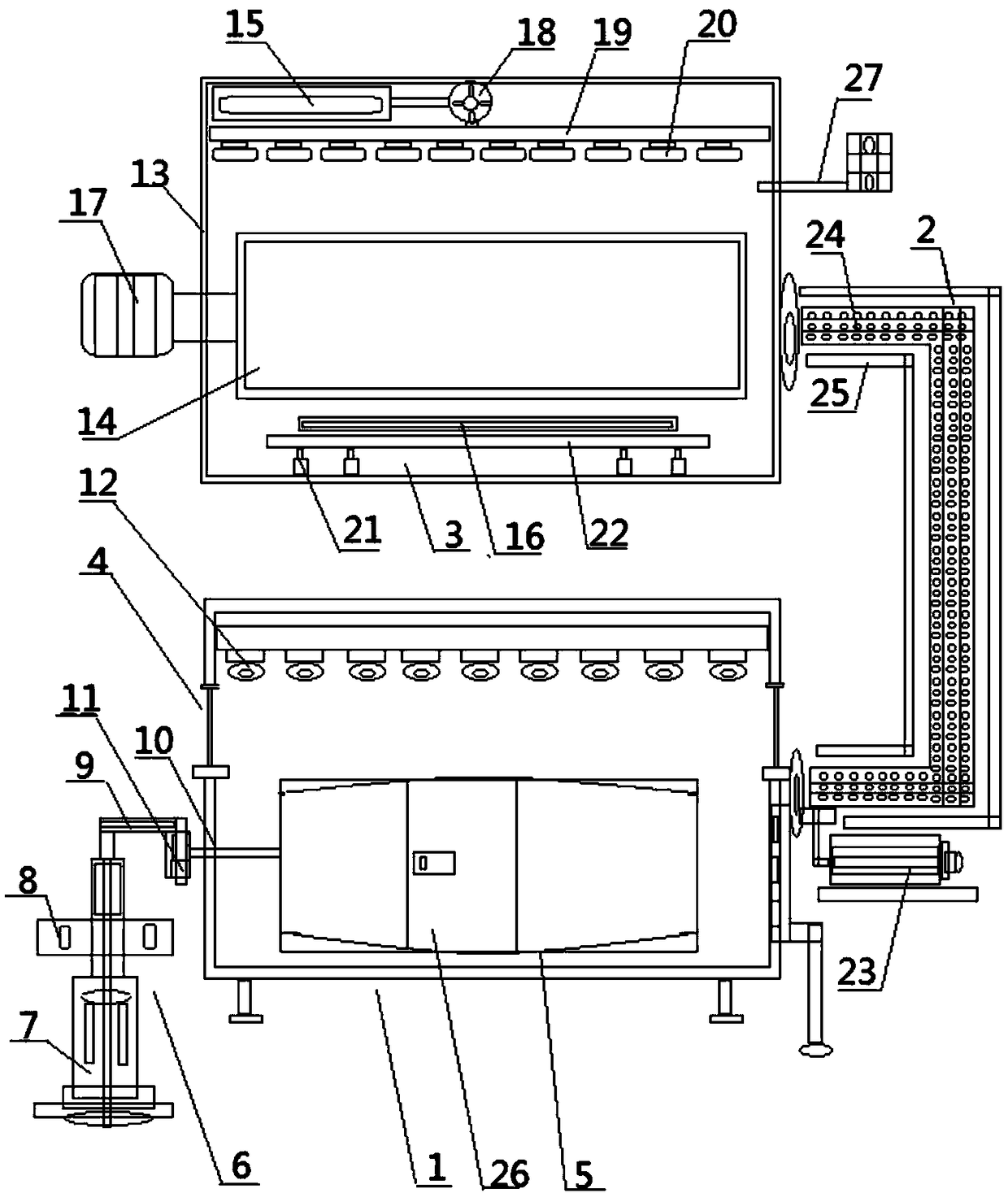

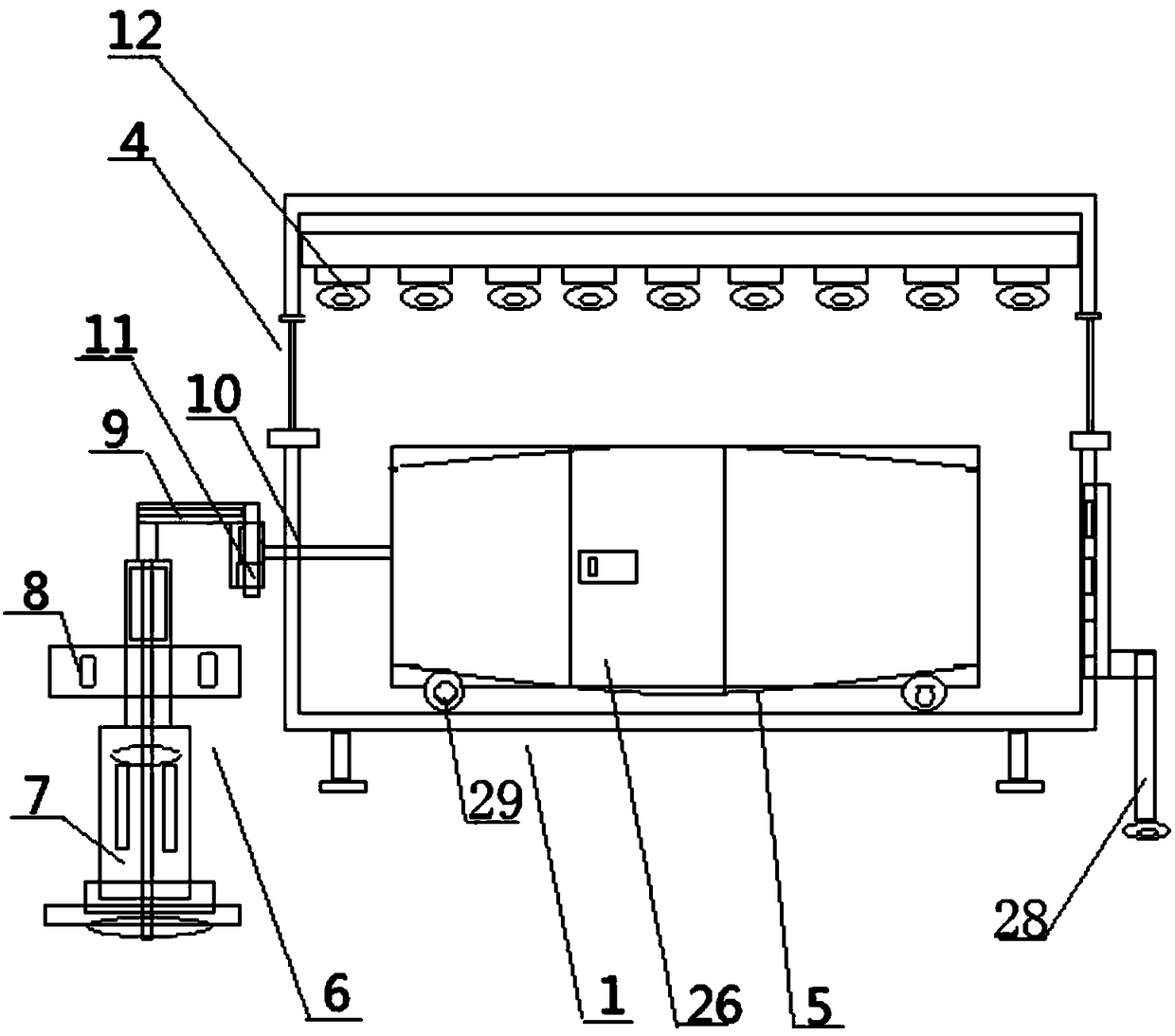

[0027] The technical scheme of a washing and drying device for honeysuckle provided by the present invention will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention and implement it.

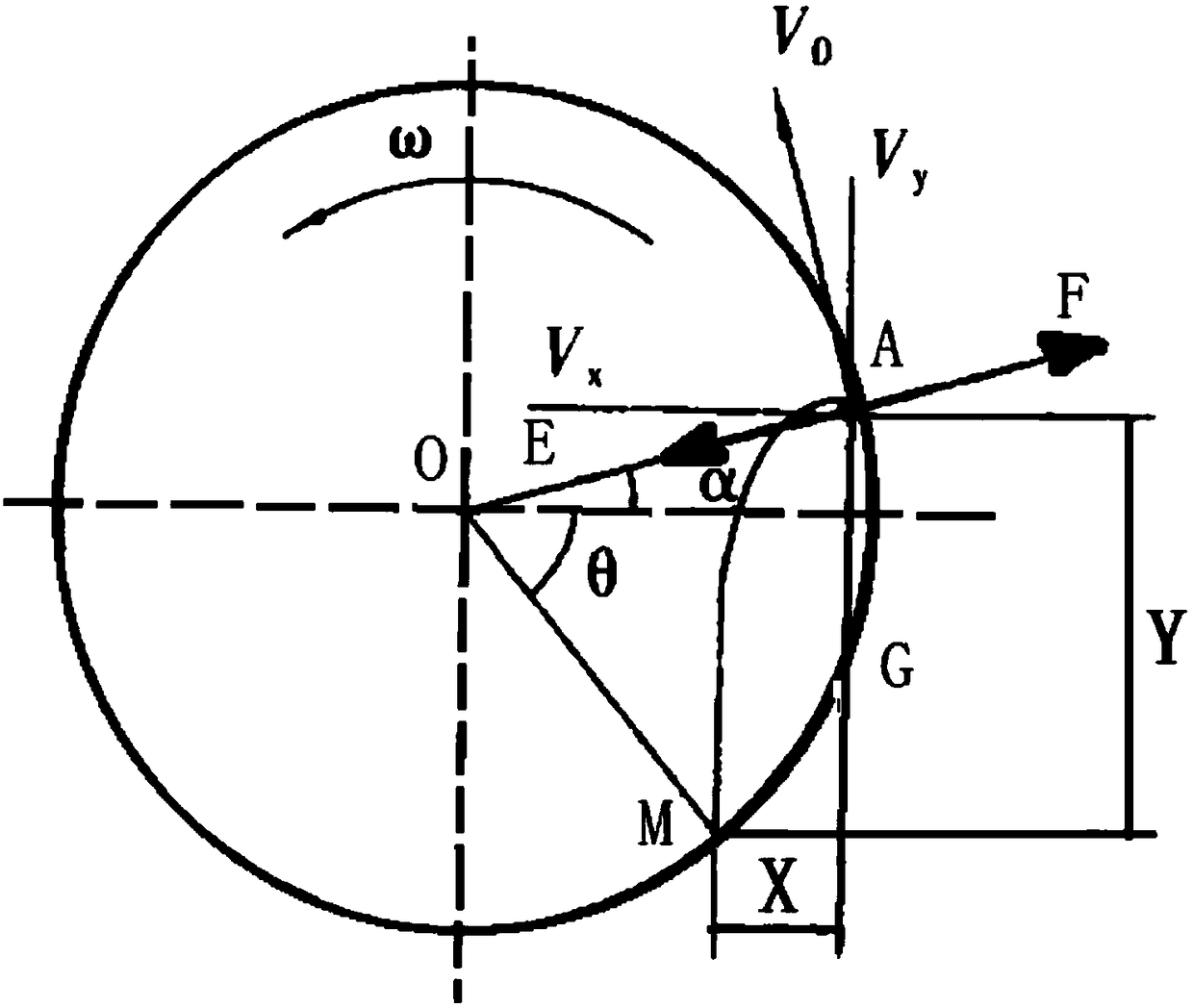

[0028] see Figure 1 to Figure 3 , a cleaning and drying device for honeysuckle, comprising a cleaning and removing impurities machine 1, a conveying device 2 and a honeysuckle drying machine 3. The honeysuckle first completes the ash removal and cleaning in the cleaning and impurity removal machine 1, and then passes through the water filtration and transmission of the transmission device 2 to the honeysuckle dryer 3, and completes the drying step in the honeysuckle dryer 3. The transmission and transshipment of honeysuckle among the various devices is completed through the transfer device 2 with manual assistance. The whole processing process is integrated, the operation is convenient, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com