A rapid performance inspection device for high-voltage insulating parts

A high-voltage insulation and inspection device technology, applied to measuring devices, parts of electrical measuring instruments, instruments, etc., can solve problems such as uneconomical, product damage, and poor alignment of inner cone bushings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

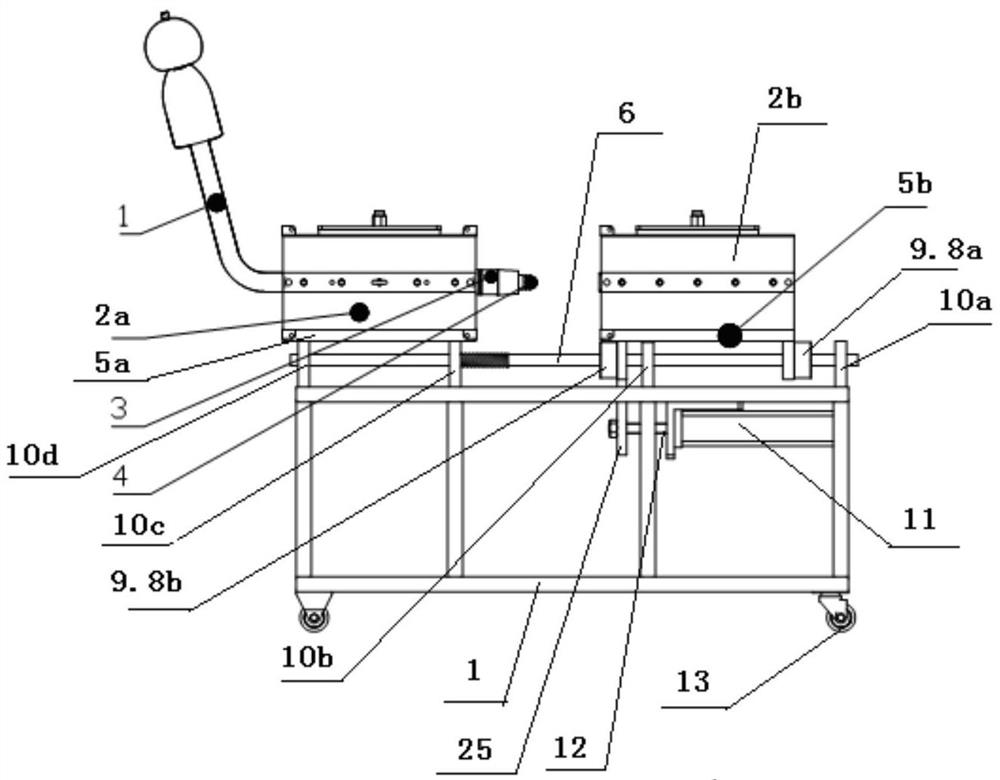

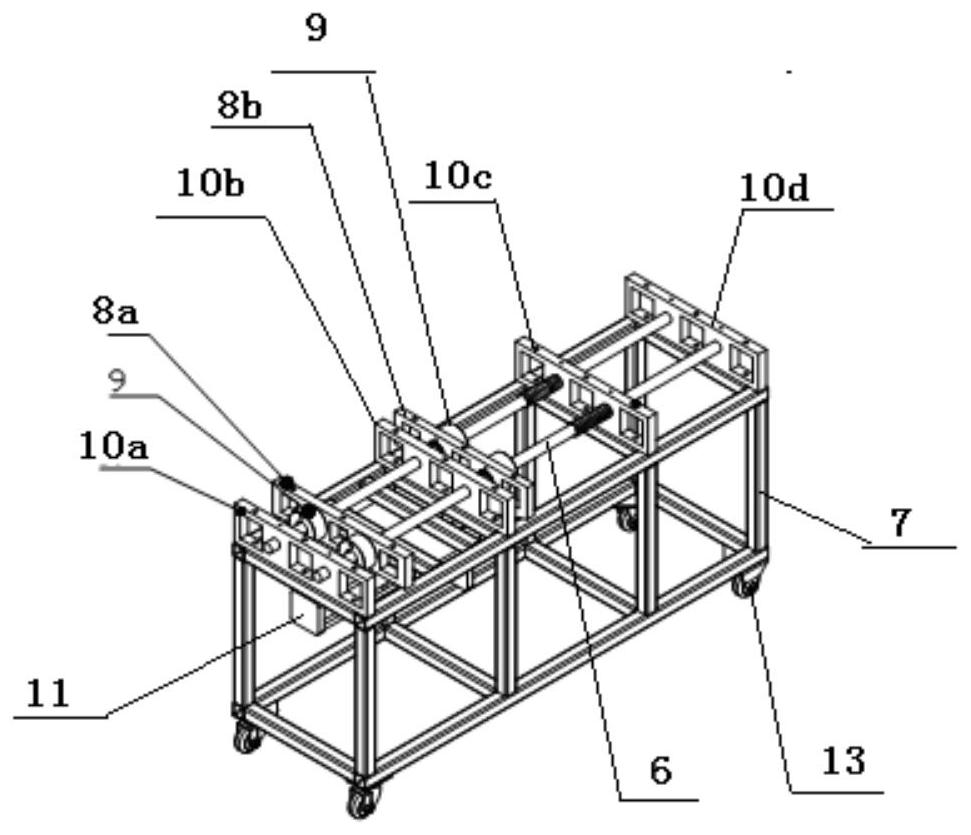

[0031] The present invention is a kind of rapid performance testing device for high-voltage insulating parts, see Figure 1 to Figure 3 , can be realized through the following structure, the specific structure includes:

[0032] A frame 1, frame 1 adopts metal material to be made, is frame structure, is provided with pulley 13 at the bottom of frame 1, to move conveniently.

[0033] Four support plates 10a, 10b, 10c, 10d are fixedly installed at the two ends and the middle position of the top of the frame 1, and two moving guide rails 6 are supported in parallel on the four support plates 10a, 10b, 10c, 10d. Two slide plates 8a, 8b are slidably installed on the motion guide rail 6 through four slide bearing seats 9, one slide plate 8a is located between the two support plates 10a, 10b, and the other slide plate 8b is located between the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com