Fault detection method for defects of disc type insulator

A basin-type insulator and fault detection technology, applied in measuring devices, processing response signals of detection, instruments, etc., can solve the problem of inability to measure the size of partial discharge TV discharge, there is no detection method and system, and it is impossible to judge the severity of defects And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below through examples, and the following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0048] A fault detection method for pot insulator defects, comprising the following steps:

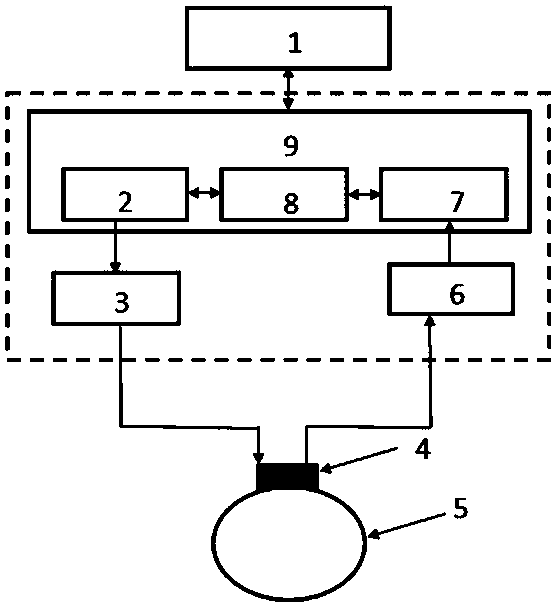

[0049] Step 1: Build a pot insulator defect fault detection system, such as figure 1 As shown, the pot insulator defect detection system includes a host computer 1 , a power amplifier module 3 , a detection transducer 4 , a pot insulator 5 , a preamplifier module 6 and a multi-channel signal control and processing module 9 . The multi-channel signal control and processing module 9 includes a multi-channel excitation signal generation unit 2 , a multi-channel echo signal processing unit 7 and a timing control unit 8 .

[0050] A detection transducer 4 is arranged on the pot insulator 5, the upper computer 1 is connected to the multi-channel signal control and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com