B-pillar assembly part-level collision test device and test method

A technology for collision test and components, applied in the field of B-pillar assembly component-level collision test device, can solve the problems of different deformation modes, difficult to reflect performance, difference in constraint boundary conditions, etc., to achieve low cost and shorten development and optimization cycle , the effect of accurate assessment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

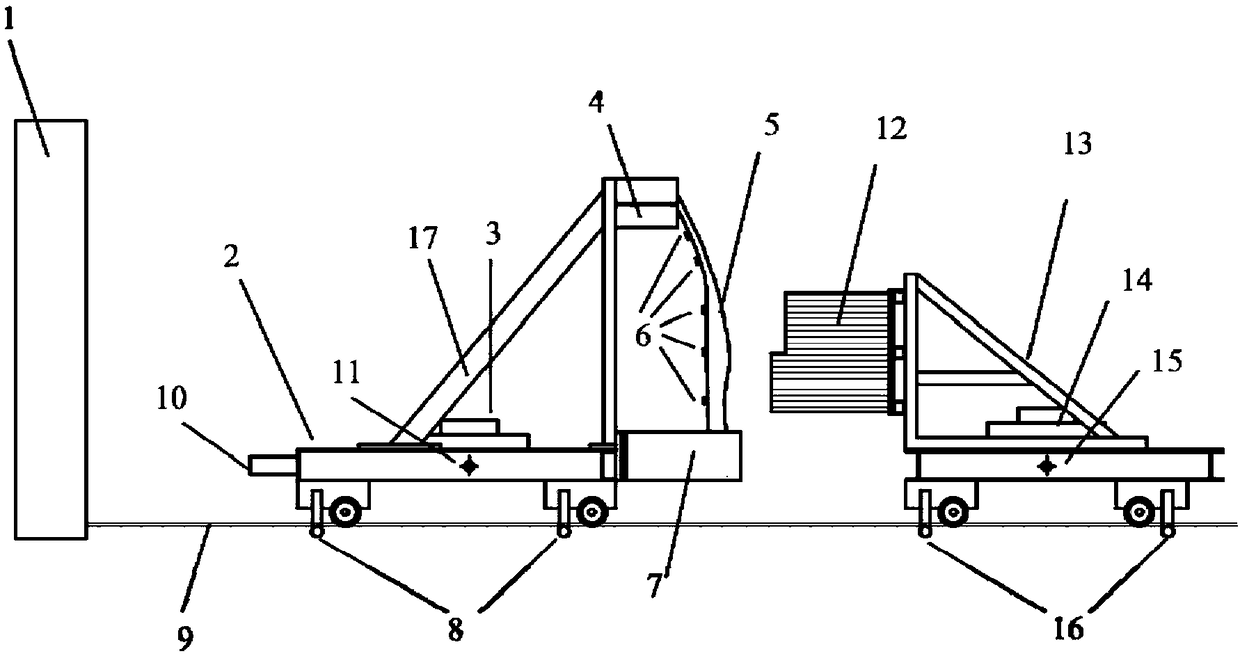

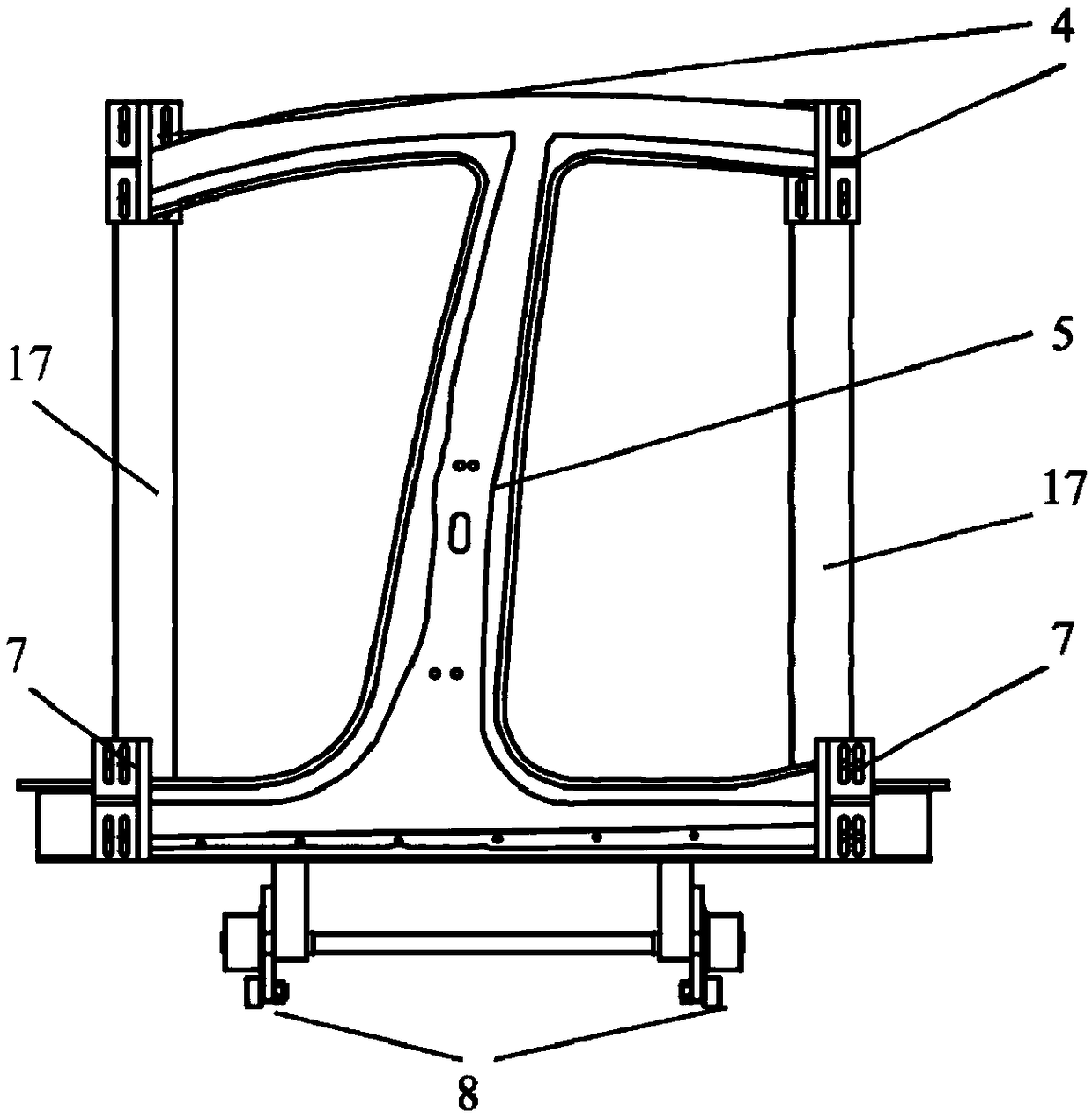

[0030] A B-pillar assembly component level crash test device, such as Figure 1~2 As shown, it includes a rigid wall 1, a bumped trolley 2 and a collision trolley 13. The bumped trolley 2 is used for rigid connection with the B-pillar assembly 5, and the collision trolley 13 and the bumped trolley 2 are installed on the same guide rail 9 Among them, a buffer mechanism is provided between the impacted trolley 2 and the rigid wall 1, and the collision trolley 13, the impacted trolley 2 and the rigid wall 1 are arranged in sequence according to the initial velocity direction of the collision trolley 13.

[0031] In this embodiment, the B-pillar assembly 5 includes the B-pillar and the B-pillar assembly upper side beam connected to the B-pillar and the B-pillar assembly threshold beam. And the lower fixed plate 7 of the B-pillar assembly, and the counterweight 3 of the bumped trolley is arranged, the buffer mechanism 10 and the coupler wheel 8 of the bumped chassis are installed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com