Horizontal pulling force metering device of micro force value dynamometer

A technology of measuring device and dynamometer, which is applied in the direction of measuring device, force/torque/work measuring instrument calibration/test, instrument, etc. Accurate measurement of indication values, etc., to achieve the effect of ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

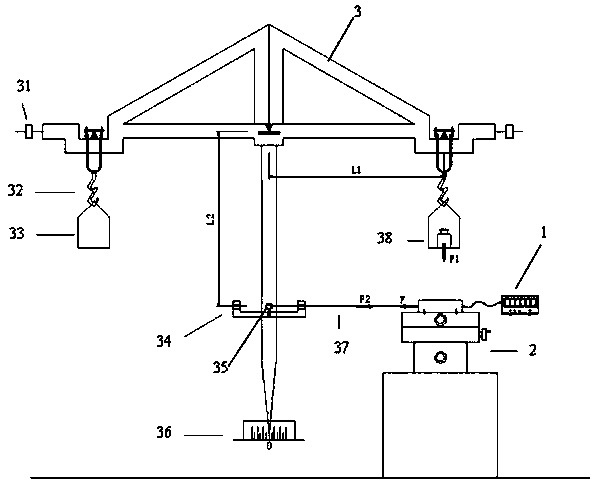

[0021] Such as figure 1 As shown, the micro force value dynamometer horizontal pulling force measurement device of the present invention comprises a dynamometer 1, a working platform 2, and an equiarm balance 3, and the dynamometer 1 is horizontally fixed on the working platform 2, and is characterized in that , a small hole 35 is vertically arranged on the arm of the equal-arm balance 3 balance indicating needle bar, the distance L2 between the small hole 35 and the main knife edge of the balance is equal to the distance L1 between the main knife edge and the hanging weight tray, and the small hole 35 passes through the light and thin Line 37 is connected to the load cell 1 sensor. The small hole 35 is equipped with a horizontal observation hole 34 through which the lightweight thin wire 37 passes to observe the levelness of the lightweight thin wire 37 . The working platform 2 can be adjusted in X, Y, Z three-dimensional directions.

[0022] When the maximum weighing value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com