Integrated Bluetooth automatic testing system

An automatic test system and an integrated technology, applied in the direction of measuring devices, measuring device casings, instruments, etc., can solve the problems of individual training of operators, single testing methods, and low efficiency, so as to ensure test quality, save personnel costs, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

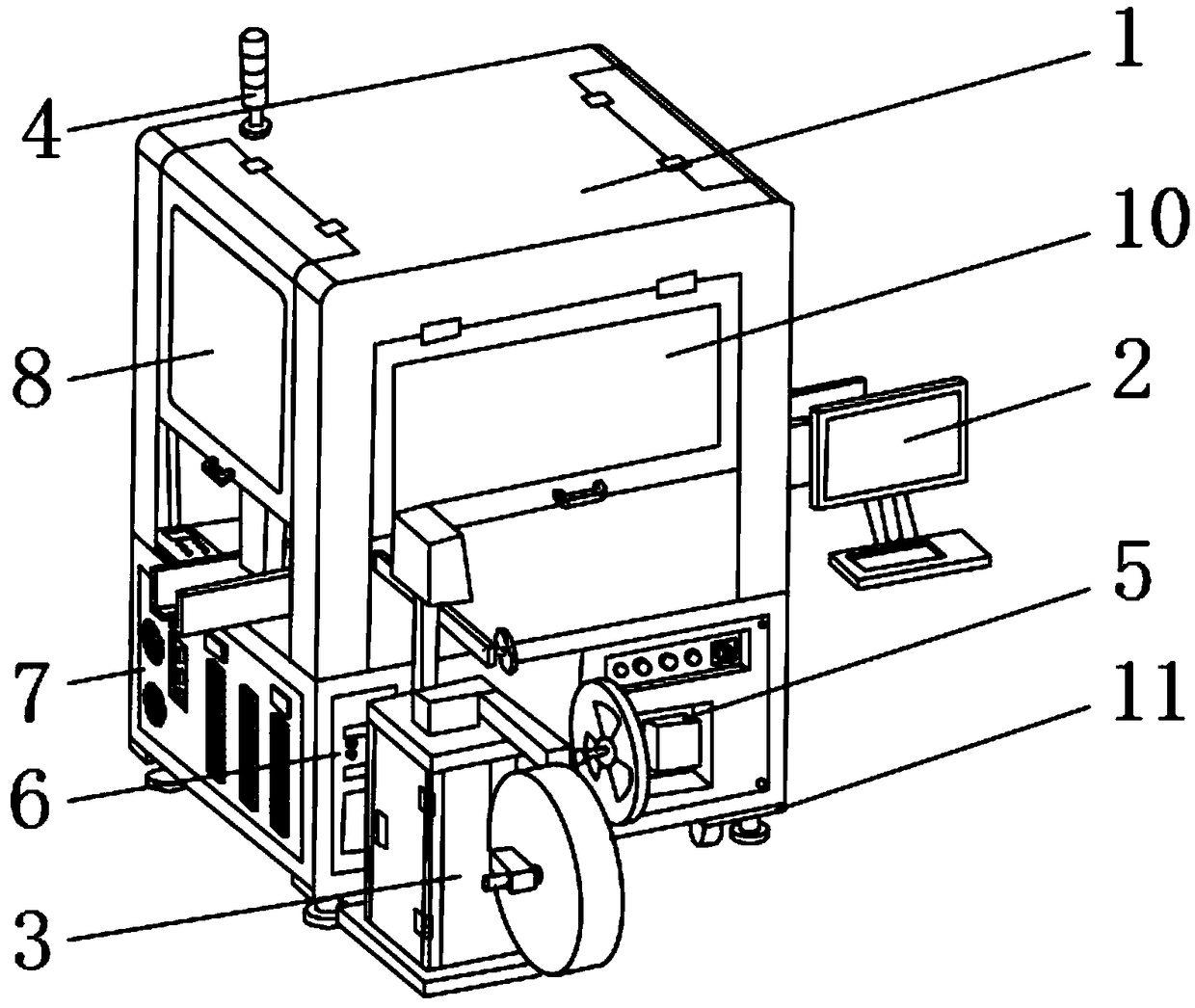

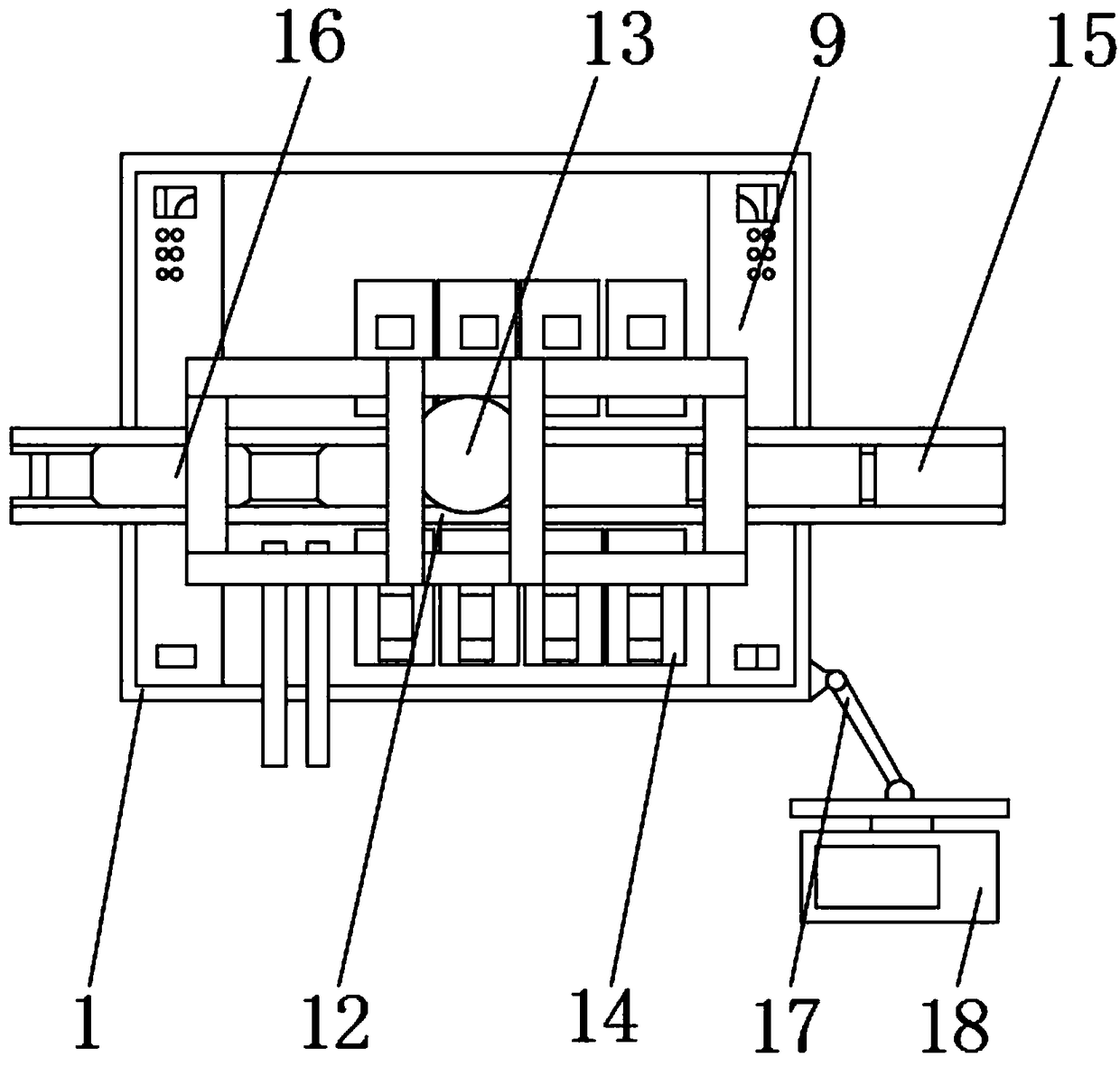

[0022] Such as Figure 1-2 As shown, an integrated Bluetooth automatic test system includes a main box 1, a monitor display 2 is arranged on one side of the main box 1, and a single-discharge taping device 3 is arranged near the front of the main box 1. Red, green, and yellow warning lights 4 are welded on the upper outer surface of the box 1 near the rear corner. The front outer surface of the main box 1 is close to the lower end with an oil-water separator 5 fixed by bolts. The front outer surface of the main box 1 is close to An industrial computer 6 is fixedly installed at the lower end position by bolts, and the industrial computer 6 is located below the single-discharge taping device 3. The inside of the main box 1 is fixedly installed with a table by bolts, and the outer surface of the upper end of the table is fixed with bolts. Intermediate docking station 12 connects the entire system with other equipment to realize the automation of the entire test. It uses machines t...

Embodiment 2

[0024] Such as Figure 1-2 As shown, an integrated Bluetooth automatic test system, one side of the outer surface of the main box 1 is close to the lower end, and a lower side plate 7 is fixedly installed by bolts, and the upper side of the lower side plate 7 is located on one side of the outer surface of the main box 1 through The hinge is movably installed with an upper side plate 8. The main box 1 is provided with two sets of support plates 9 inside. The front outer surface of the main box 1 is close to the upper position, and an observation board 10 is fixedly installed through the hinges. The lower outer surface of the main box 1 The connecting plate 11 is fixedly installed near the four corners by bolts, and the Bluetooth shielding box 14 is provided under the six-axis manipulator 13, which can automate the signal shielding test of the Bluetooth chip 16, thereby reducing manual operations by operators, improving production quality and speeding up The production speed impr...

Embodiment 3

[0026] Such as Figure 1-2 As shown, an integrated Bluetooth automatic test system, the single-discharge taping device 3 includes a control box, a conveying track, and a taping reel. The lower outer surface of the control box is fixedly installed with a base; the upper side plate 8 One side of the outer surface near the lower end and the front outer surface of the observation board 10 near the lower end are both fixedly installed with handles by bolts; the upper outer surface of the pallet 18 is provided with a keyboard placement slot near one side to monitor the rear end of the display 2 The surface is fixedly connected to the connecting frame 9 by bolts; the middle of the docking station 12 is provided with a conveyor belt, the number of the Bluetooth shielding boxes 14 is two groups, and the number of each group of Bluetooth shielding boxes 14 is four. The shielding box 14 is provided with a test seat inside. The intermediate docking station 12 is located between the two set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com