Reflective low-temperature wood-plastic profile

A wood-plastic profile and reflective technology, applied in the direction of sheets/boards, building elements, etc., can solve the problem of inconvenient protection operation of foam tape wrapping wood-plastic profiles, insufficient space utilization efficiency and firmness, and inconvenient disassembly of packaging items, etc. problems, to achieve the effect of convenient and flexible storage and taking, improve packaging quality and efficiency, convenient and flexible disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the present invention will be further explained in conjunction with specific implementations below.

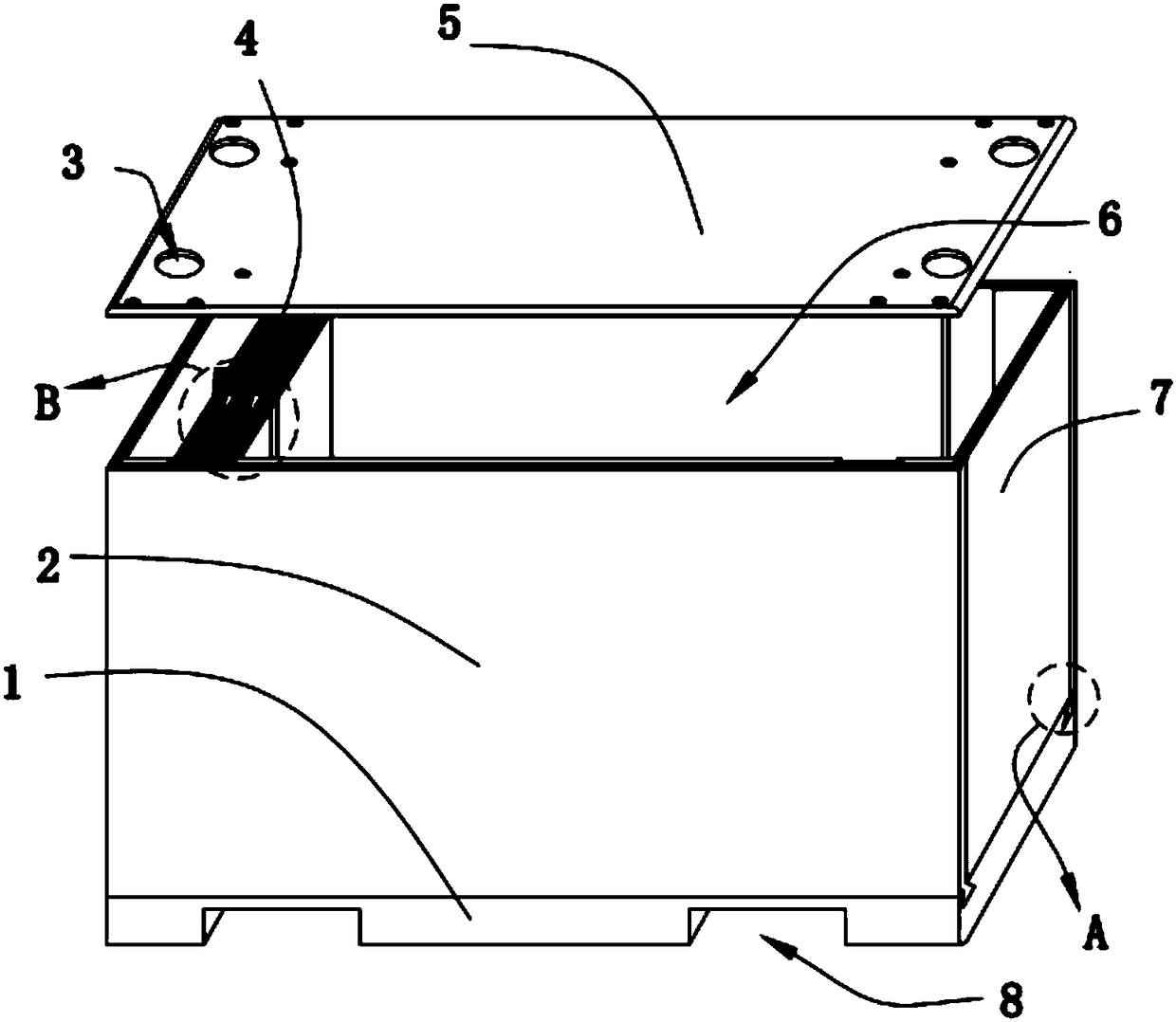

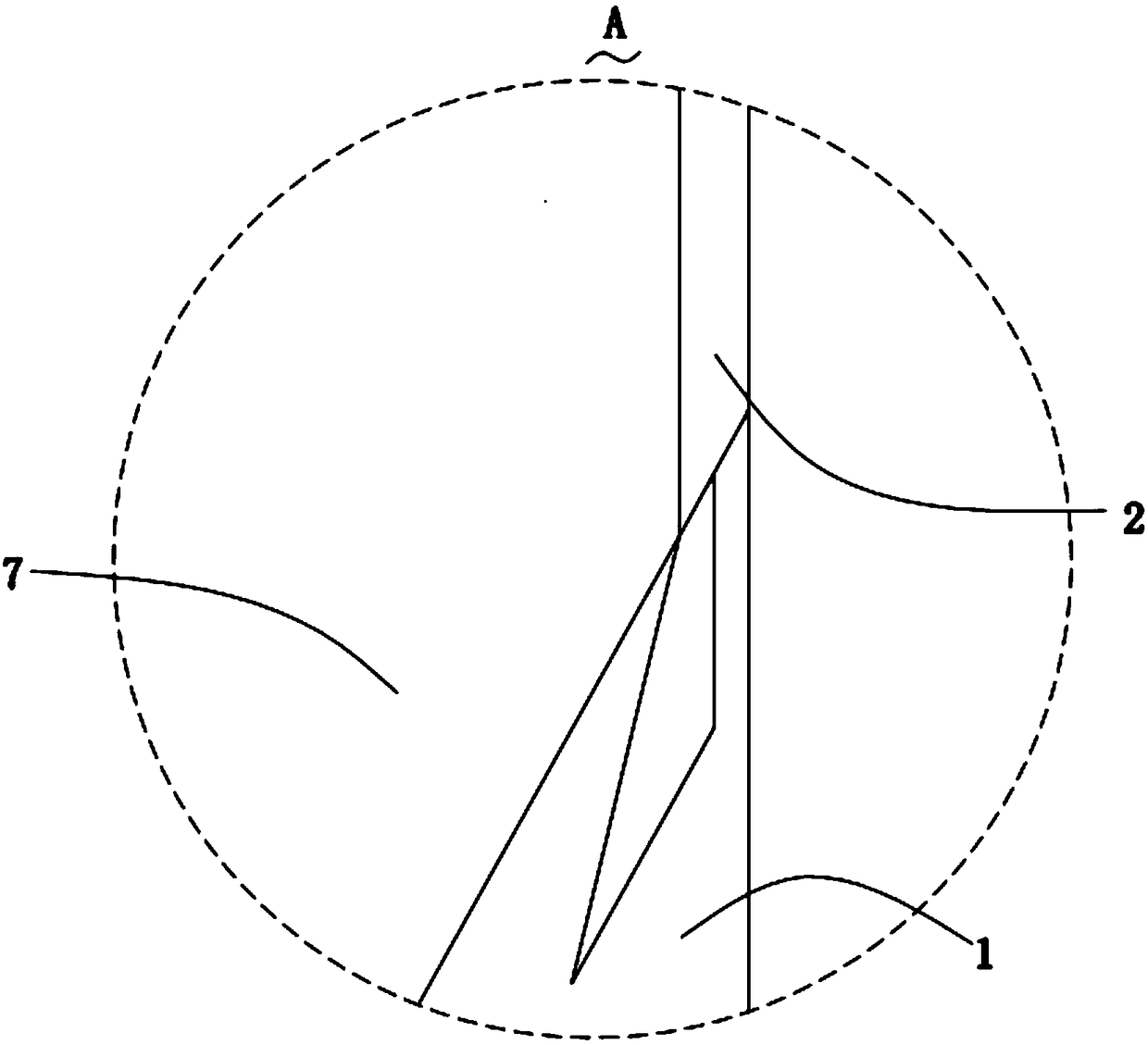

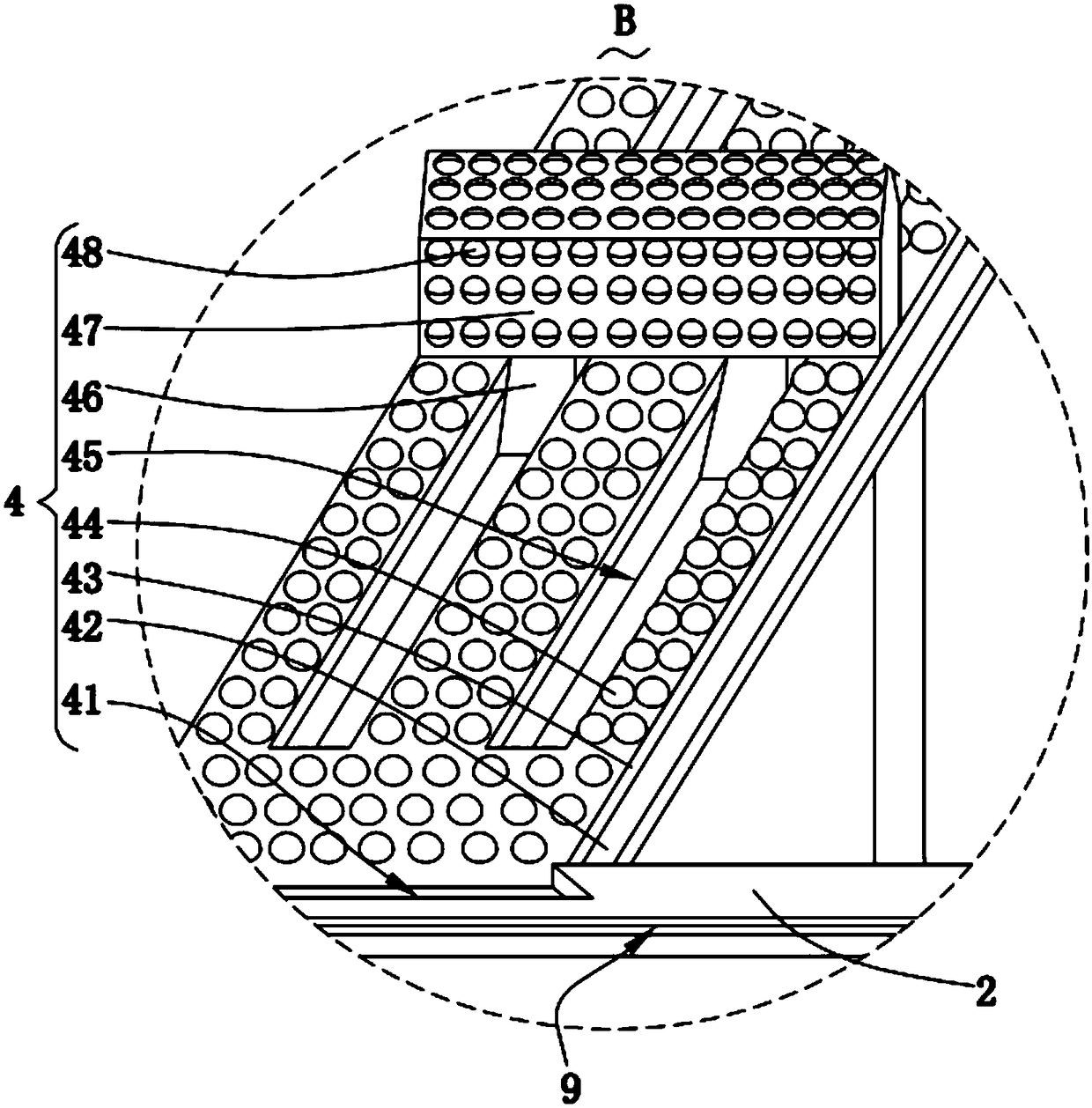

[0028] Such as figure 1 , image 3 with Image 6 As shown, the reflective low-temperature wood-plastic profile of the present invention includes a bottom plate 1, two first baffles 2, a limiting hole 3, a limiting structure 4, a sealing structure 5, a storage chamber 6, and two second The second baffle plate 7, the conveying groove 8, the sealing groove 9 and the limiting block 9a; the bottom end of the bottom plate 1 is equipped with a rectangular shape of a reflective low-temperature wood-plastic profile extruded with a PVC resin coated with a color reflective coating on the surface of the forklift Structure of the conveying trough 8; the four edges of the top surface of the bottom plate 1 are symmetrically provided with two first baffles 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com