Power clutch system and executing mechanism

An actuator and power technology, applied in the field of power clutch systems and actuators, can solve problems such as lack of self-locking function, low efficiency of work, and increased heat dissipation of the transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It can be seen from the background technology that the execution function of the current actuator needs to be improved. The following is a concrete analysis of the reasons for an executive mechanism.

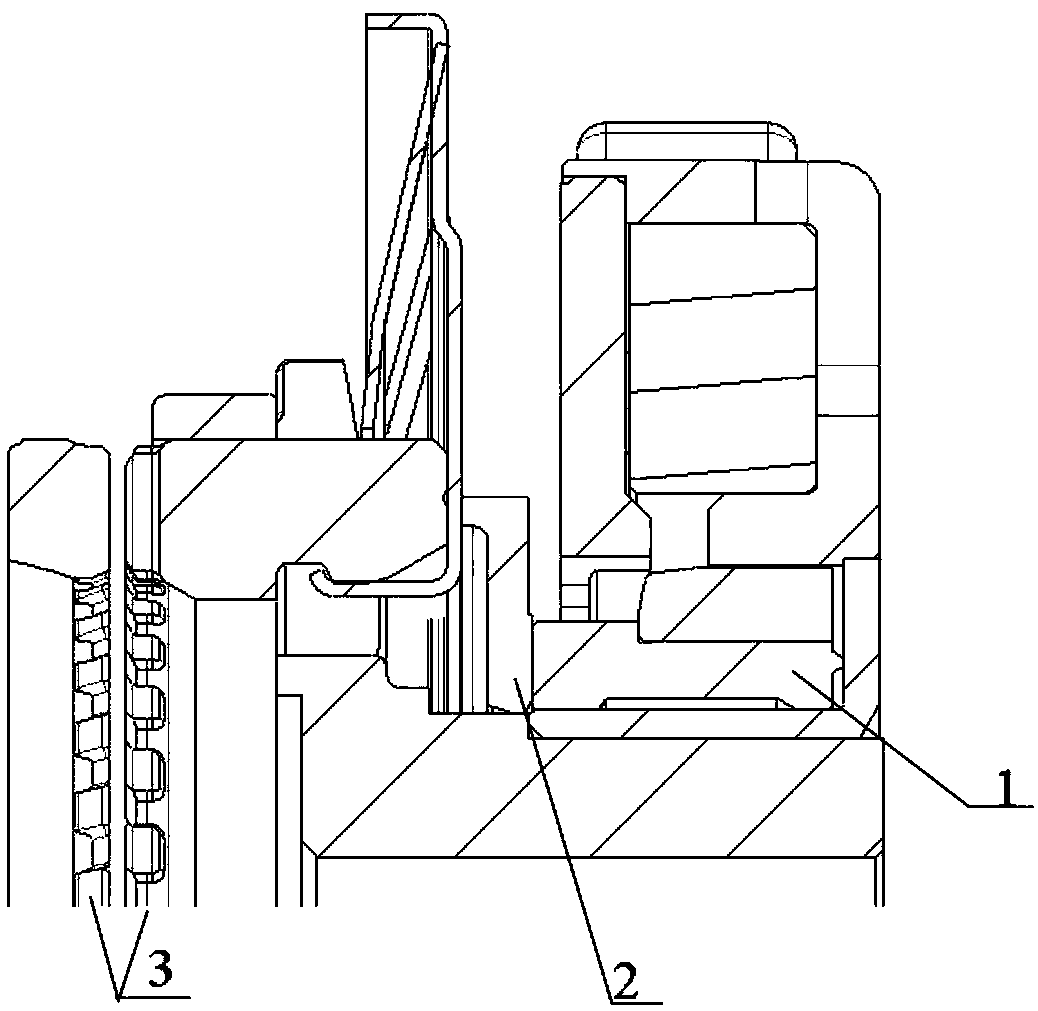

[0038] figure 1 It is a sectional view of an actuator.

[0039] Such as figure 1 As shown, the actuator includes a push rod 2, a moving part and a diaphragm spring. When the circuit is connected, the electromagnetic clutch 1 pushes the push rod 2 to move forward, the push rod 2 acts on the diaphragm spring, and the diaphragm spring acts on the moving part , the moving part acts on the gear 3, and the final result is that the two gears 3 are meshed, so that the power can be transmitted.

[0040] It can be seen that in order to maintain the state of the two gears 3 meshing with each other, the diaphragm spring must always act on the moving part, that is, the circuit must always be turned on, otherwise the moving part will be unable to provide the force acting on the diap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com