Man-powered hydraulic pump with high-reliability

A reliable, hydraulic pump technology, applied to the components, pumps, piston pumps, etc. of the pumping device for elastic fluids, can solve the problems of reducing the reliability of the pump, affecting the oil absorption speed, insufficient oil absorption, etc. The effect of speed increase, pressure holding performance improvement, and oil absorption speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

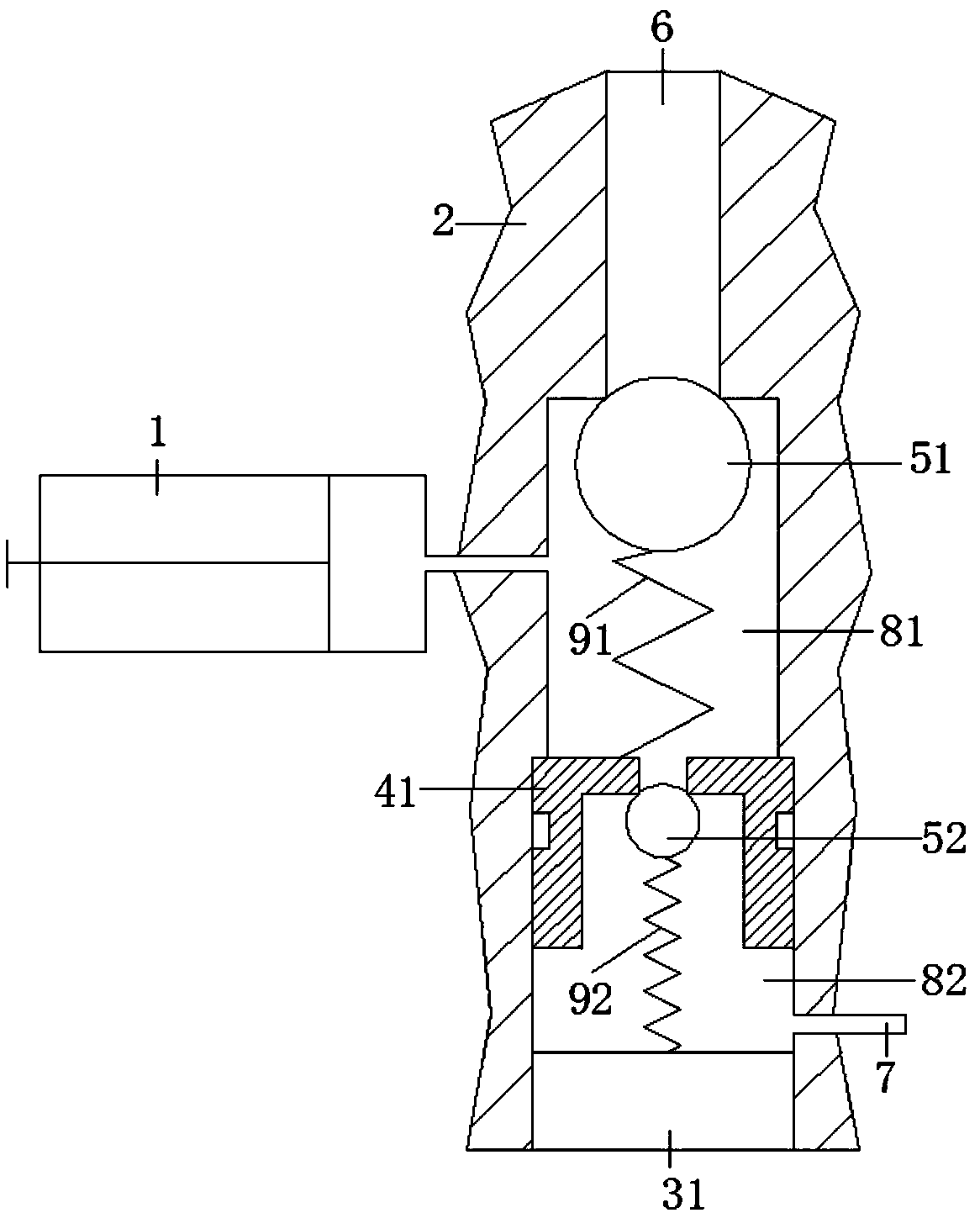

Embodiment 1

[0037] A high-reliability manual hydraulic pump includes a cylinder body 1, a valve body 2, and an oil inlet hole 6, an oil suction valve chamber 81, an oil outlet valve chamber 82, and an oil outlet hole 7 that are sequentially connected. The oil suction valve chamber, the oil outlet valve chamber and the oil outlet hole are all arranged in the valve body, and an oil suction sealing ball 51 is arranged on the oil inlet of the oil suction valve chamber, and the oil suction sealing ball 51 arranged in the oil suction valve chamber The first elastic member seals the oil-suction sealing ball on the oil inlet of the oil-suction valve chamber; since the cylinder is connected to one side of the oil-suction valve chamber, the piston of the cylinder can be reciprocated by manpower Displacement, when the displacement of the piston increases the volume of the space connected between the oil suction valve chamber and the cylinder body, the pressure of the space connected between the oil s...

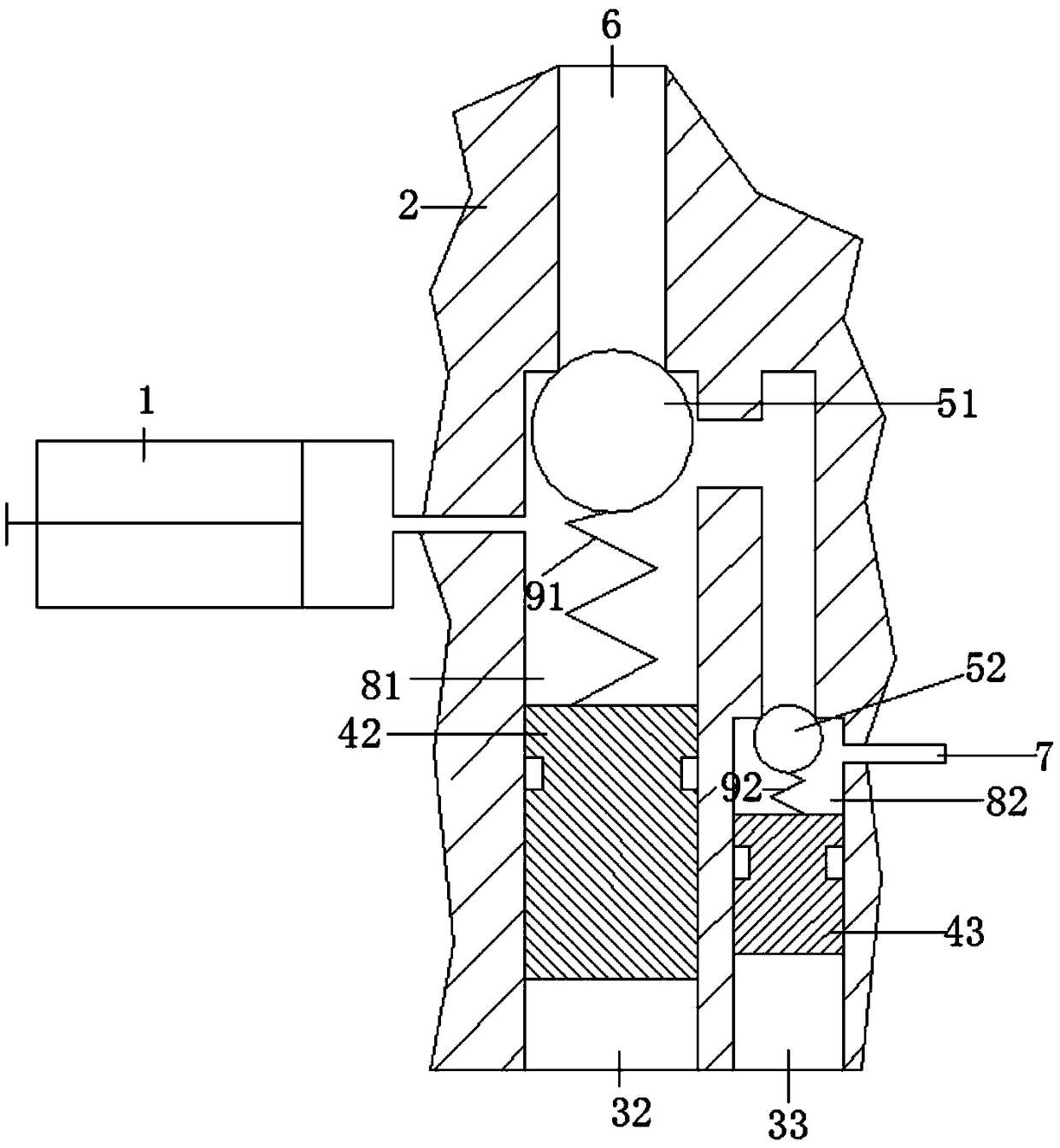

Embodiment 2

[0045] In this embodiment, the oil suction sealing ball and the oil outlet sealing ball are installed in the valve body through different installation inlets, and the oil inlet of the oil suction valve chamber has a larger diameter than the oil inlet of the oil outlet valve chamber Specifically, the oil outlet valve chamber can be arranged in parallel with the oil suction valve chamber, so designed, it is convenient to make the aperture of the oil inlet of the oil suction valve chamber larger than that of the oil outlet valve chamber in terms of design and manufacture. The aperture of the oil inlet, when designing and manufacturing, make the inner diameter of the oil suction valve chamber larger than the inner diameter of the oil outlet valve chamber to make the aperture of the oil inlet of the oil suction valve chamber larger than the oil inlet of the oil outlet valve chamber Similarly, the aperture size of the oil inlet and outlet of the valve body can be changed. The increas...

Embodiment 3

[0049] In this embodiment, the oil suction sealing ball and the oil outlet sealing ball are installed in the valve body through different installation inlets, and the oil inlet of the oil suction valve chamber has a larger diameter than the oil inlet of the oil outlet valve chamber Specifically, the oil outlet valve chamber and the oil suction valve chamber are vertically arranged, so designed, it is convenient to make the aperture of the oil inlet of the oil suction valve chamber larger than the inlet of the oil outlet valve chamber in terms of design and manufacture. The aperture of the oil port, when designing and manufacturing, make the inner diameter of the oil suction valve chamber larger than the inner diameter of the oil outlet valve chamber to make the aperture of the oil inlet of the oil suction valve chamber larger than that of the oil inlet of the oil outlet valve chamber The aperture, similarly, can change the aperture size of the oil inlet and outlet of the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com