Open caisson foot blade provided with seal brush

A technology with sealing and sealing brush, which is applied in the direction of caisson, building, infrastructure engineering, etc. It can solve the problems of seeping into the well, affecting the effect of construction or retaining wall, and major engineering accidents, so as to achieve the effect of small frictional resistance and preventing the failure of mud retaining wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

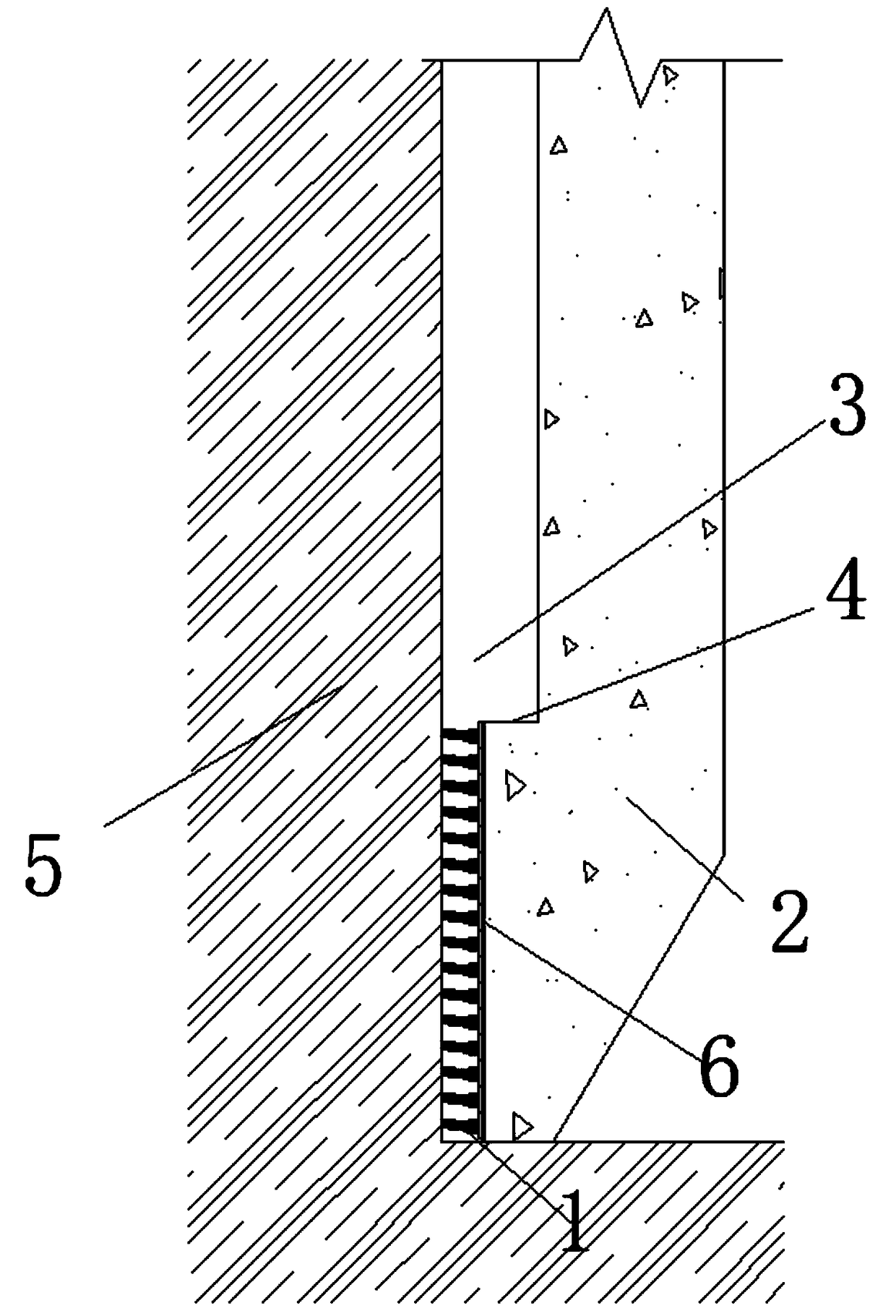

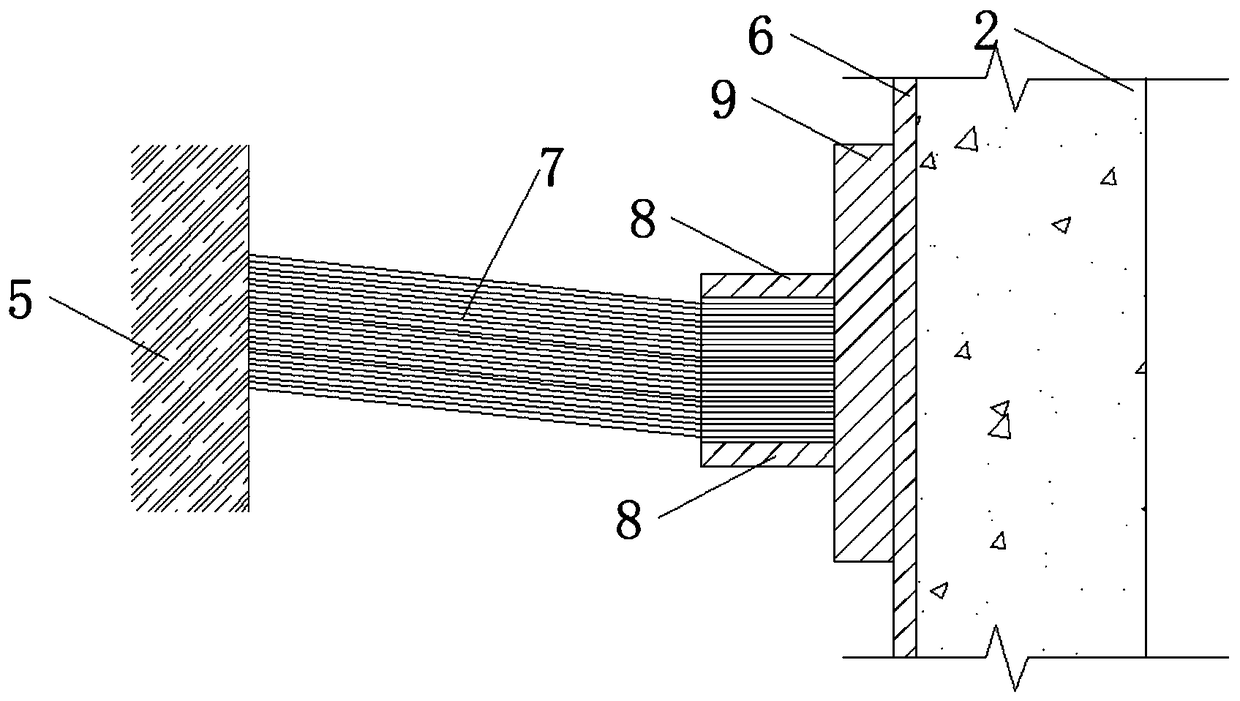

[0017] combined with Figure 1-2 Said caisson blade foot with sealing brush includes caisson blade foot 2, rock and soil body 5 behind the wall, mud tank 3 behind the wall, and also includes sealing brush 1, and the rock and soil body behind the wall of the caisson blade foot 2 5 One side is a step structure, the caisson blade foot 2 above the step surface 4 is adjacent to the rock and soil body behind the wall 5, and the mud tank 3 behind the wall is between the side of the wall and the rock and soil body 5 behind the wall, and the caisson blade foot 2 is below the step surface 4 A sealing brush 1 is provided between the side of the wall-side rock-soil body 5 and the wall-side rock-soil body 5. The seal brush 1 includes brush teeth and a fixed bottom pla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap