Comfortable non-ironing cotton warp knitted shirt fabric and production method thereof

A non-iron cotton and fabric technology, applied in warp knitting, fabric surface trimming, heating/cooling fabrics, etc., can solve the problems that are difficult to meet the requirements of shirt dimensional stability and shape retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] Comfortable non-ironing cotton warp-knitted shirt fabric Comfortable non-ironing cotton warp-knitted shirting fabric, the fabric contains the following raw materials and mass percentages: A: 60S cotton yarn accounts for 58%, B: 50D semi-gloss polyester accounts for 42%; the 50D semi-gloss The light polyester is 50D48F semi-gloss polyester DTY.

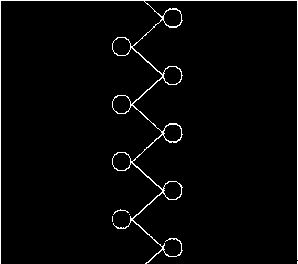

[0114] The single-comb weave structure and threading mode of the fabric are:

[0115] GB1 comb: 1-0 / 1-2 / / 7A, 8 empty wear;

[0116] GB2 comb: 1-0 / 1-2 / / 7 empty wear, 8B;

[0117] GB3 comb: 2-3 / 1-0 / 2-3 / 1-0 / 1-1 / 0-0 / 1-1 / 0-0 / 1-1 / 0-0 / / 15A;

[0118] GB4 comb: 1-1 / 0-0 / 1-1 / 0-0 / 2-3 / 1-0 / 2-3 / 1-0 / 2-3 / 1-0 / / 15B;

[0119] That is, GB1 comb: 60S cotton yarn; GB2 comb: 50D semi-gloss polyester; GB3 comb: 60S cotton yarn; GB4 comb: 50D semi-gloss polyester.

[0120] The above-mentioned comfortable non-ironing cotton warp-knitted shirt fabric, wherein the fabric uses the four combs of GB1 comb, GB2 comb, GB3 comb, and GB4 comb to wear the warp ...

Embodiment 2

[0122] Comfortable non-ironing cotton warp-knitted shirt fabric, the fabric contains the following raw materials and mass percentages: A: 30D polyester 18.8%, B: 40S cotton yarn 19%, C: 75D semi-gloss cationic polyester 31.1%, D: 75D matte polyester 31.1% % is the raw material. Specifically, A: 30D12F polyester, B: 40S cotton yarn, C: 75D72F semi-gloss cationic polyester, D: 75D72F matte polyester.

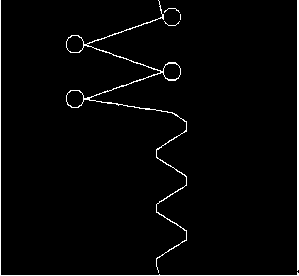

[0123] The single-comb weave structure and threading mode of the fabric are:

[0124] GB1 comb: 1-0 / 1-2 / / 2A;

[0125] GB2 comb: 1-1 / 0-0 / / 2B;

[0126] GB3 comb: 2-3 / 1-0 / / 1 empty wear, 1C;

[0127] GB4 comb: 2-3 / 1-0 / / 1D, 1 empty wear;

[0128] That is, GB1 comb: 30D polyester; GB2 comb: 40S cotton yarn; GB3 comb: 75D semi-gloss cationic polyester; GB4 comb: 75D matte polyester.

[0129] The above-mentioned comfortable non-ironing cotton warp-knitted shirt fabric, wherein the fabric uses the four combs of GB1 comb, GB2 comb, GB3 comb, and GB4 comb to wear the warp flat or variab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com