Cabin door air vent mechanism directly driven by handle and driving method thereof

A vent and hatch technology, applied in the field of hatch vent mechanism and its drive, can solve the problems of increased processing, assembly and maintenance costs, complicated mechanism form, and large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

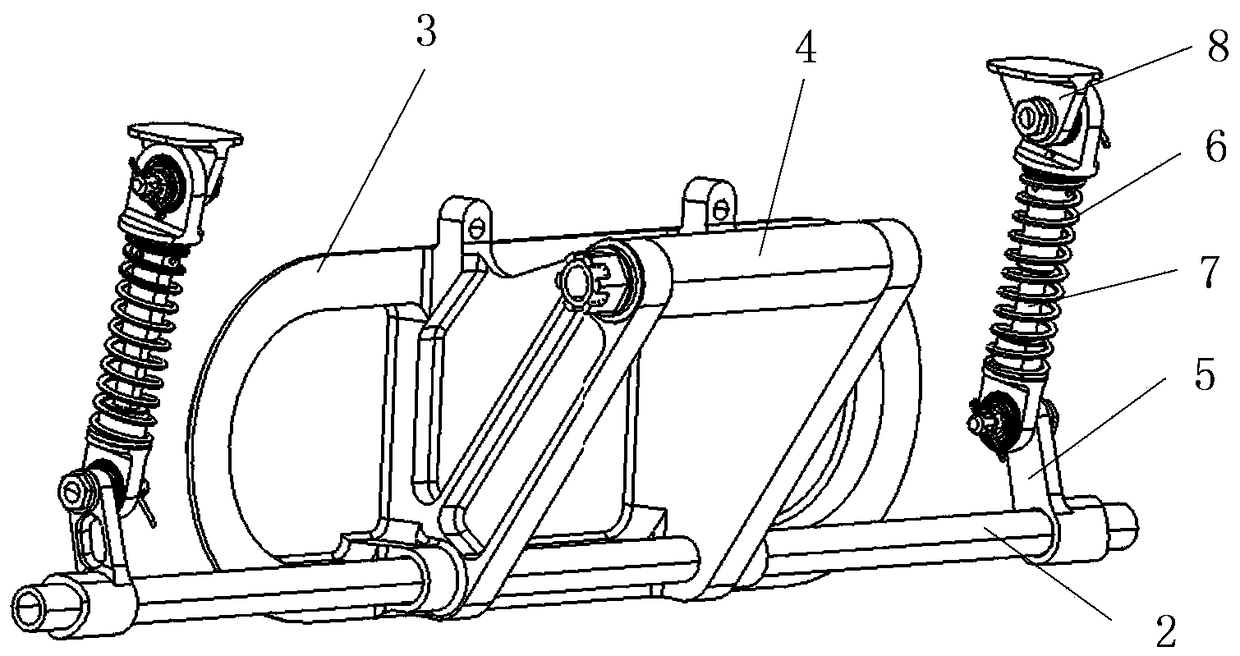

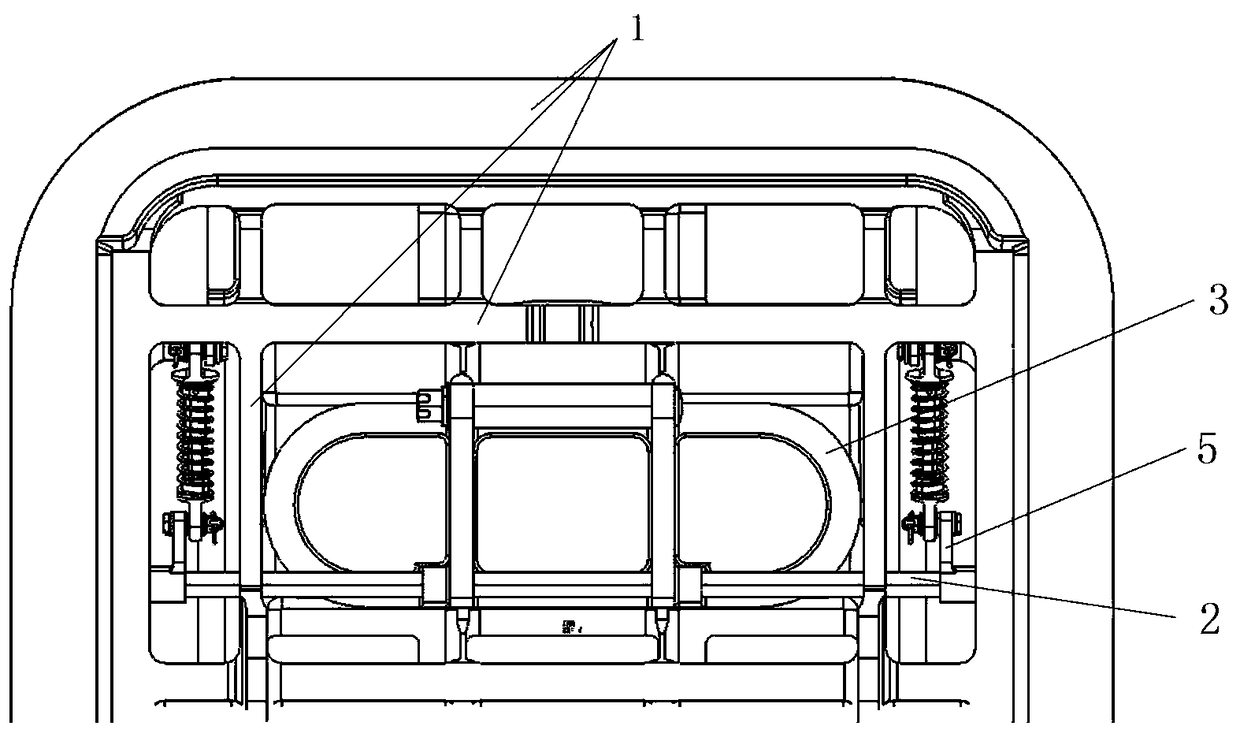

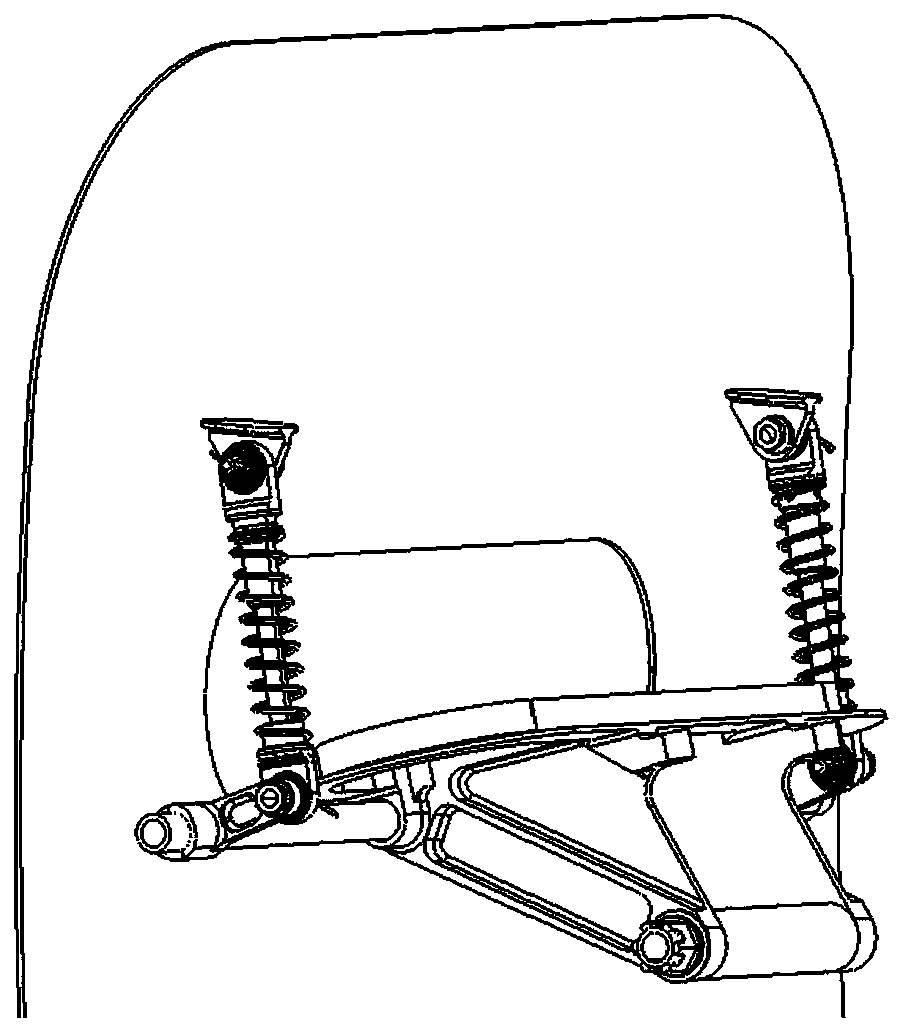

[0021] Such as Figure 1 to Figure 3 As shown, a door vent mechanism directly driven by the handle, the bottom of the vent panel 3 is fixedly connected with an inclined inner handle assembly 4, and the common connection between the vent panel 3 and the inner handle assembly 4 is connected to the vent shaft 2 , the vent shaft 2 is hingedly connected with the cabin door structure 1; a crank 5 is respectively provided at both ends of the vent shaft 2, one end of the crank 5 is fixedly connected with the vent shaft 2, and the other end is hinged to the telescopic shaft 7 through a pin shaft, The other end of the telescopic shaft 7 is hinged with the ear piece 8 fixedly arranged on the cabin door structure 1, and a compression spring 6 is coaxially arranged on the telescopic shaft 7, and the two ends of the compression spring 6 are supported on the limit platforms on both sides of the telescopic shaft 7; The compression spring 6 presses the vent panel 3 against the hatch structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com