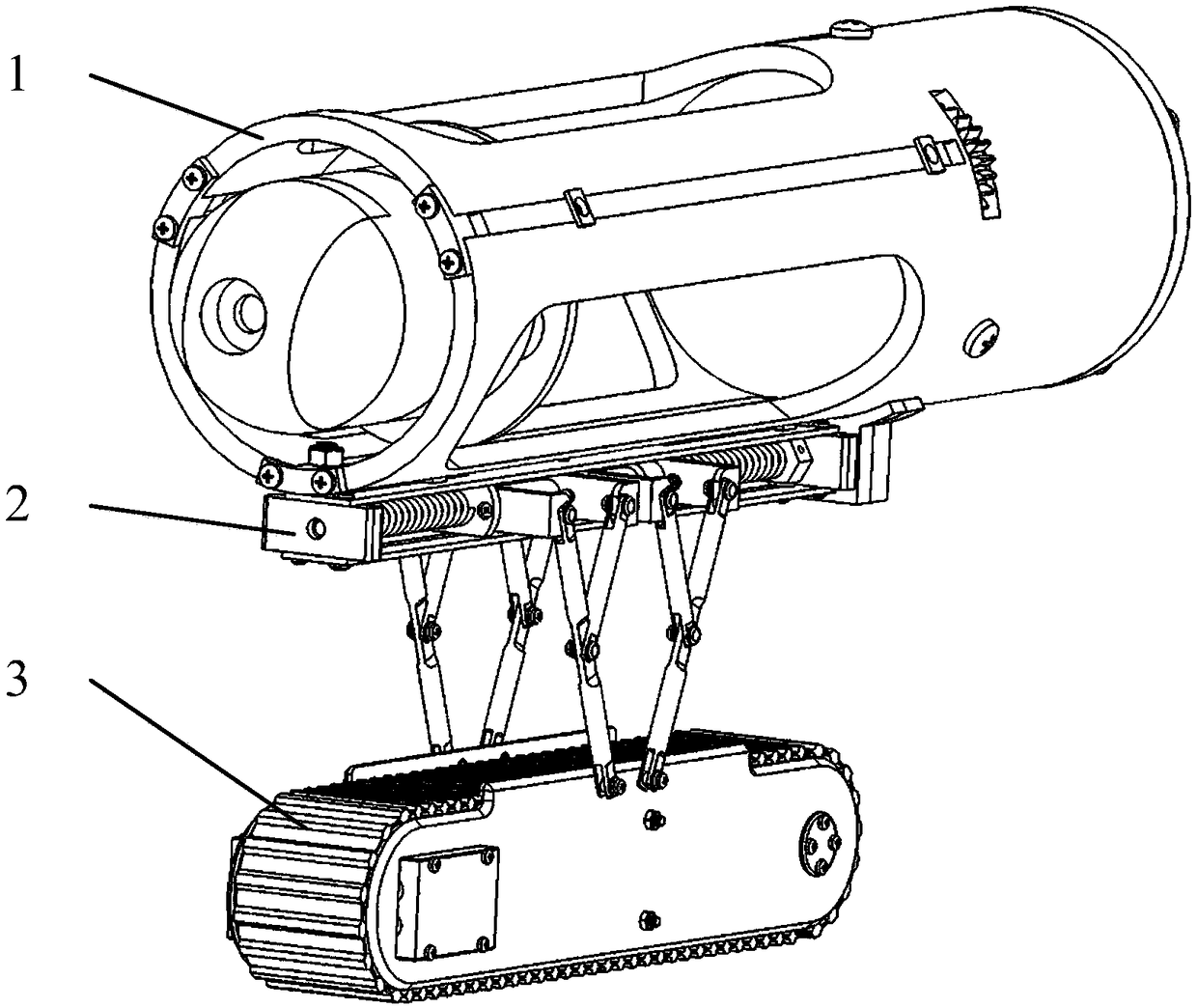

Modular support crawler-type in-pipe robot

A modular and robotic technology, applied in the field of robotics, can solve the problems of complex robot structure, low degree of modularization, and time-consuming, etc., and achieve the effect of compact structure, improved adaptability, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to facilitate those skilled in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and implementation examples. It should be understood that the implementation examples described here are only for illustration and explanation of the present invention, and are not intended to limit the present invention. invention.

[0039] Among the figure: 1. main body mechanism, 2. modular support mechanism, 3. modular crawler mechanism, 101, cylindrical frame, 102, camera pan-tilt, 103, camera pan-tilt supporting plate, 104, gear baffle plate, 105 , gear fixing frame, 106, spur gear, 107, gear supporting plate, 108, gear motor, 109, rack rear cover, 110, terminal block, 111, rack front end limit block, 112, first rack slot limit Position bar, 113, camera pan-tilt connecting block, 114, second rack slot limit bar, 115, gear baffle link block, 116, third rack sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com