Memorial archway type tension leveler and small billet continuous casting machine applying same for reduction

A technology of billet continuous casting and stretching and leveling machine, which is applied in the field of continuous casting, can solve problems such as the inability to meet billet billet parameters, short length of liquid phase zone, large distance between stretching and straightening rollers, etc., and achieve good frame rigidity , The structure is simple and compact, and the effect of ensuring the quality of the billet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

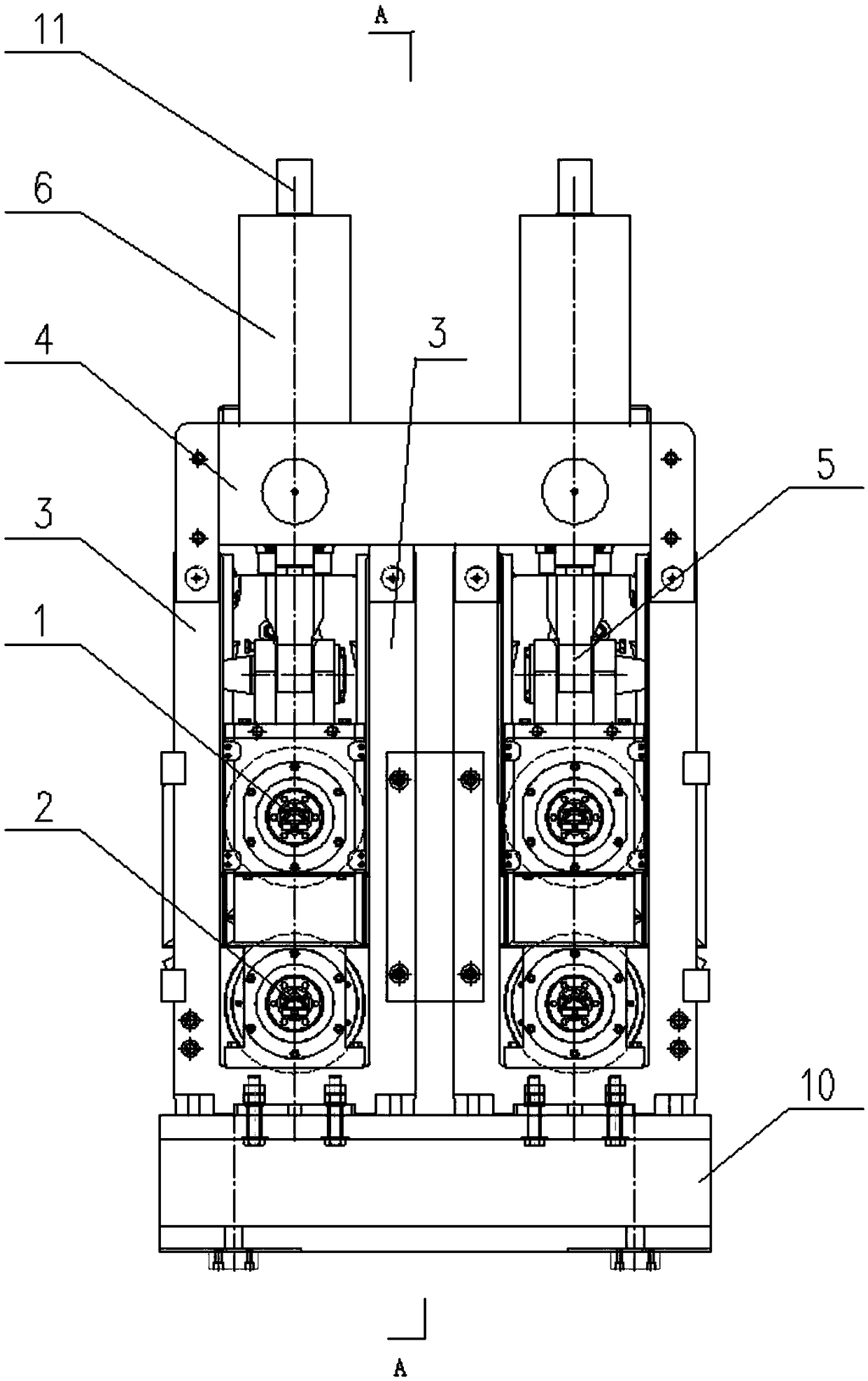

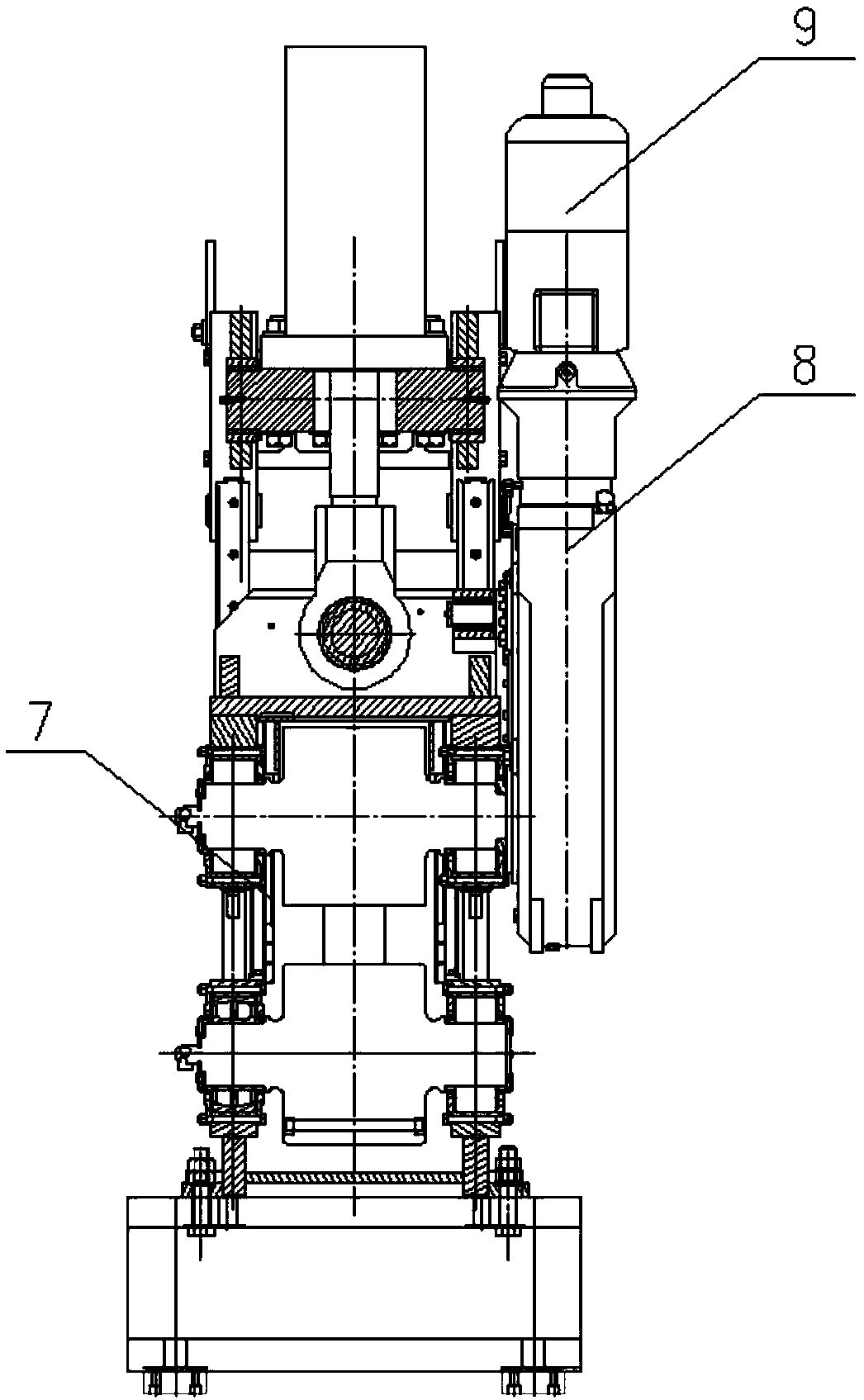

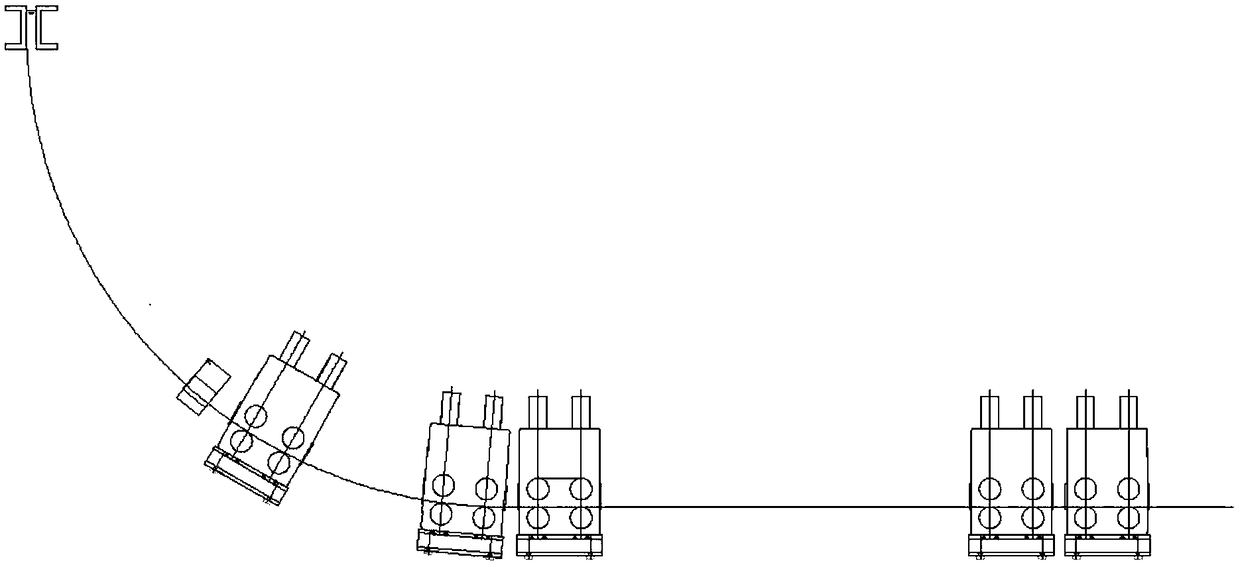

[0027] Such as figure 1 As shown, the present invention provides an archway-type tensioning and leveling machine, including: an archway-type frame, at least two sets of tension-leveling rollers located in the archway-type frame, and a lifting drive mechanism located above the archway-type frame. Specifically, the tension leveling machine consists of two sets of tension leveling rollers, four rows of column frames, an upper frame, two upper tension leveling roller movable frames, two lifting drive mechanisms (which can be hydraulic cylinders), two heat shields, It consists of two reducers, two motors, a base, two displacement sensors (placed in hydraulic cylinders) and other components.

[0028] Wherein, two groups of straightening rolls include two upper straig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com