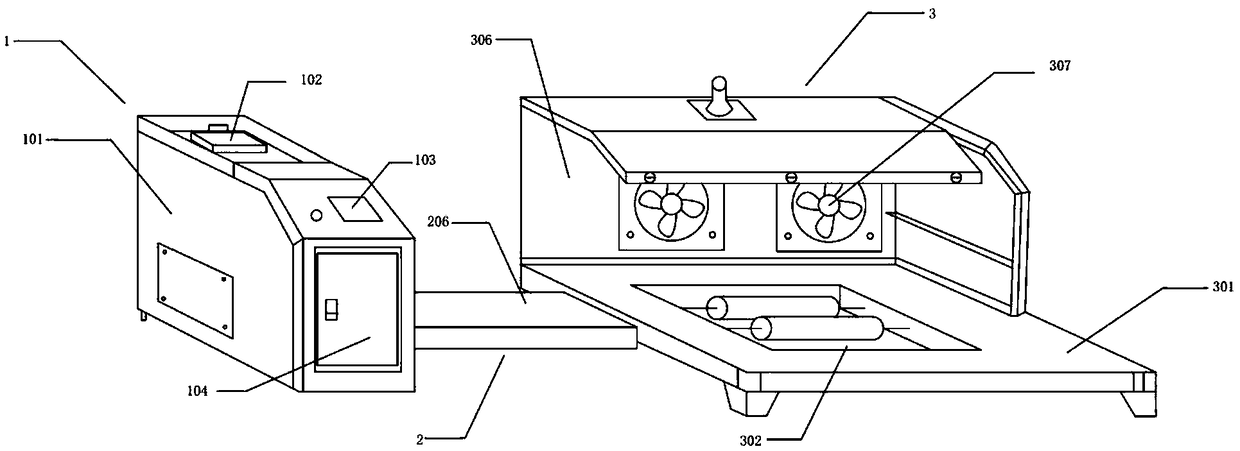

Novel tire rubber spraying machine

A glue spraying machine and glue spraying technology, which is applied in the direction of spraying device, liquid spraying device, pretreatment surface, etc., can solve problems such as easy generation of air bubbles, weakening of glue fluidity, and reduced glue spraying effect, so as to achieve the goal of reducing air bubbles Produce, reduce heating time, control flow precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

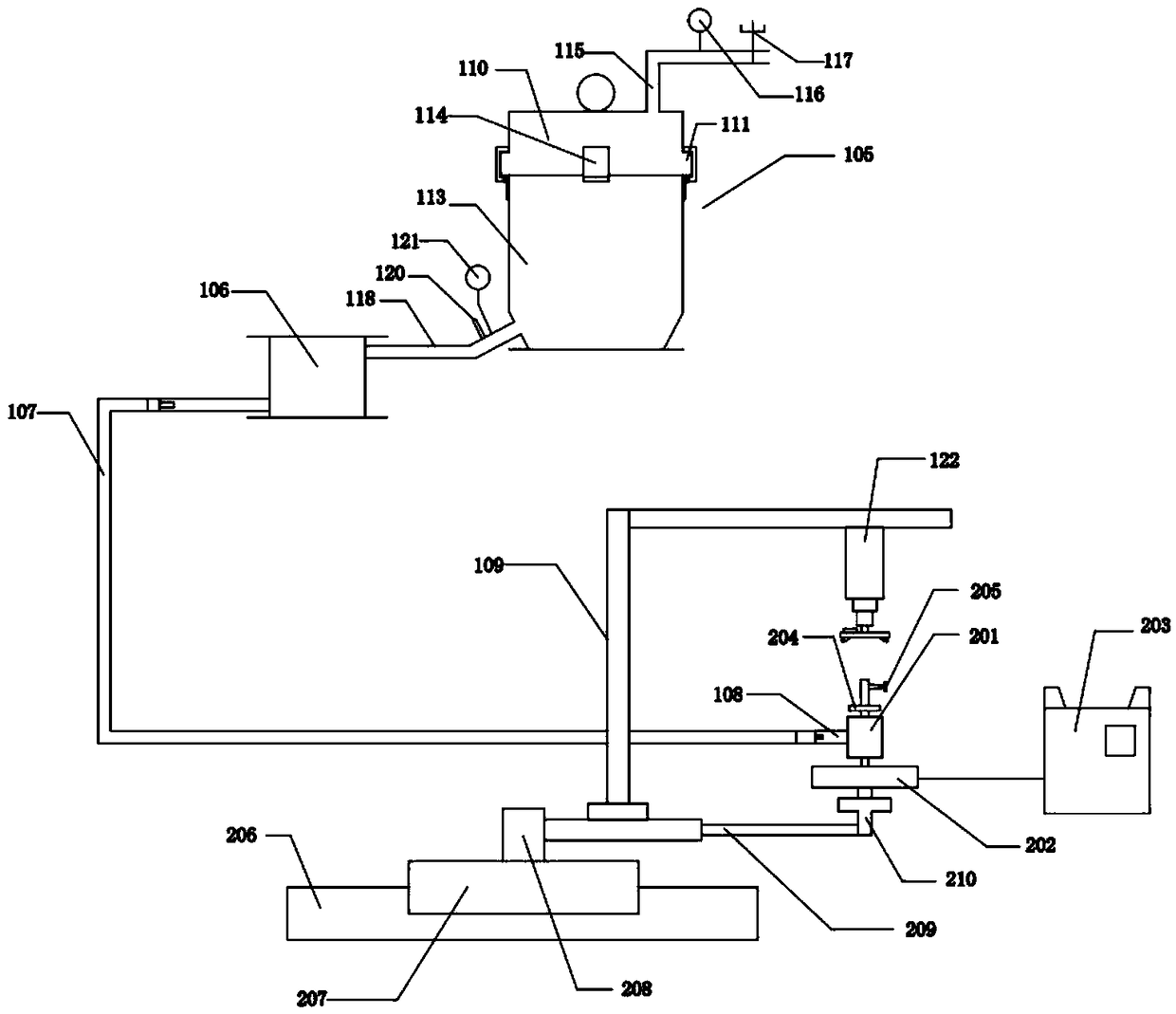

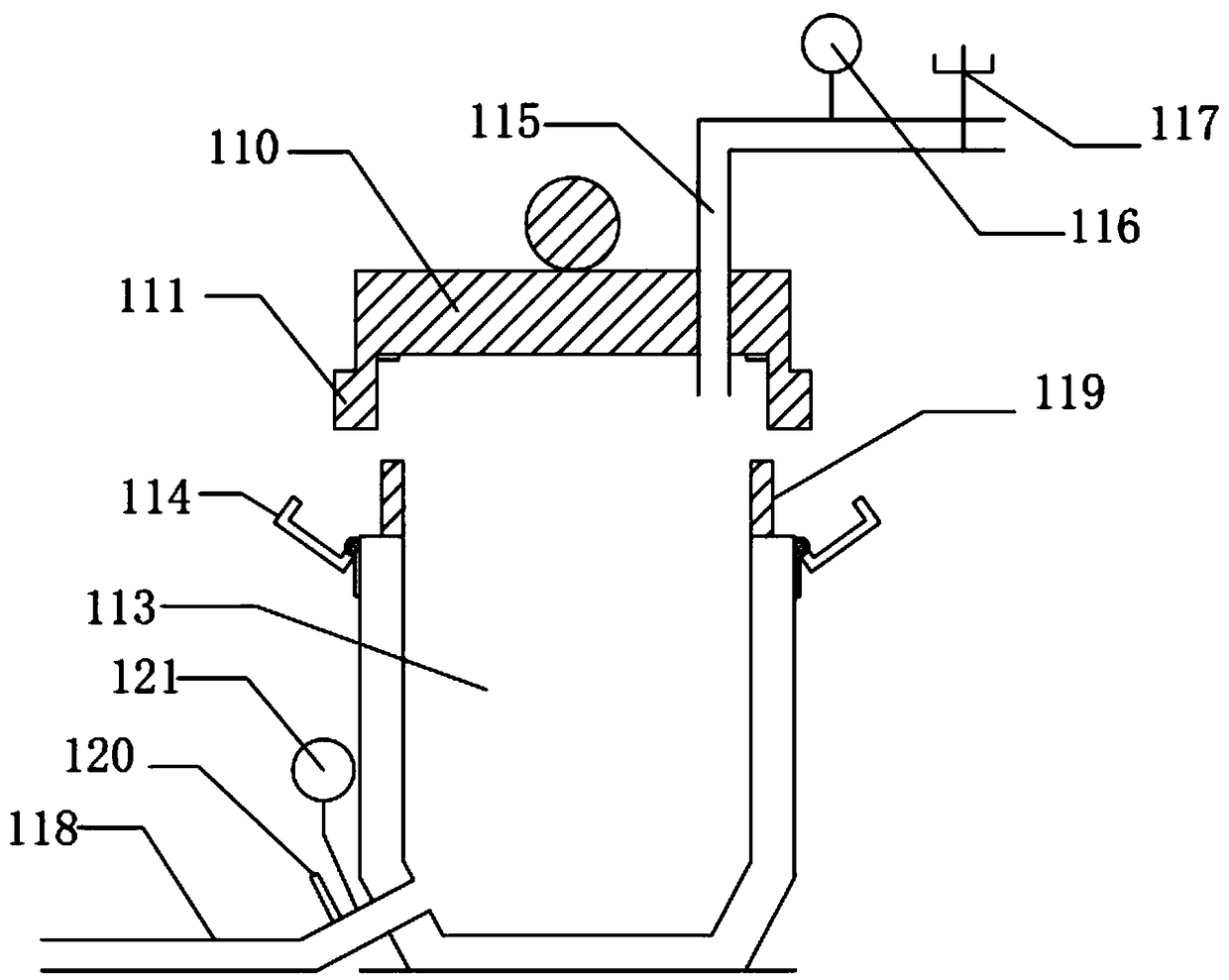

[0058] When the present invention is in use, first, the present invention is installed to a suitable position, the staff closes the valve 120, puts an appropriate amount of rubber material into the heating kettle 113 of the melting tank 105 through the upper slot hole 102, and places the sealing cover 110 in the heating tank 113. The upper side of the kettle 113, and through the cooperation of the lock and the matching block 111 and the lock and the piece 114 and the cooperation of the rubber ring 112 and the positioning ring 119, the heating kettle 113 and the sealing cover 120 are sealed and connected;

[0059] Connect the resistance wire between the inner wall and the outer wall of the heating kettle 113 to an external power source, so that the resistance wire is energized to generate heat and heat to melt the glue. During the heating process, due to the sealed connection between the heating kettle 4 and the sealing cover 1, the pressure inside the heating kettle 4 increases...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com