A method for constructing an elevator system with adjustable usable lift height

An elevator system, elevator technology, applied in the direction of lifting equipment, elevators, transportation and packaging in mines, to achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

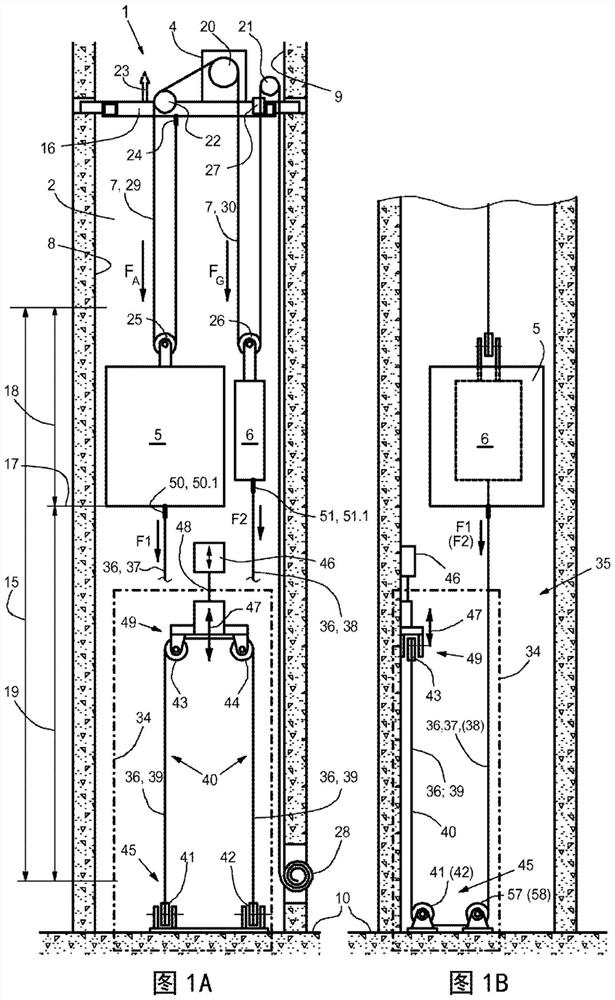

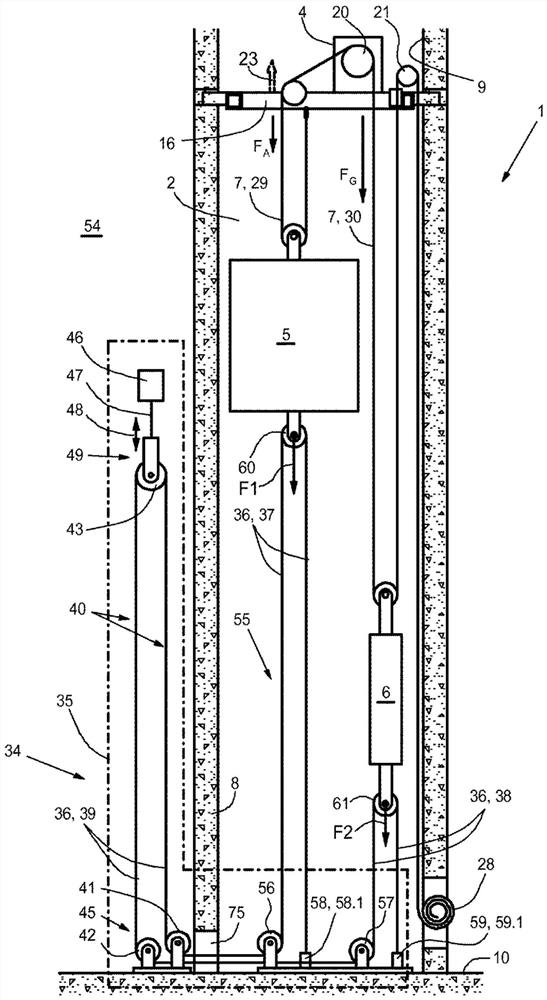

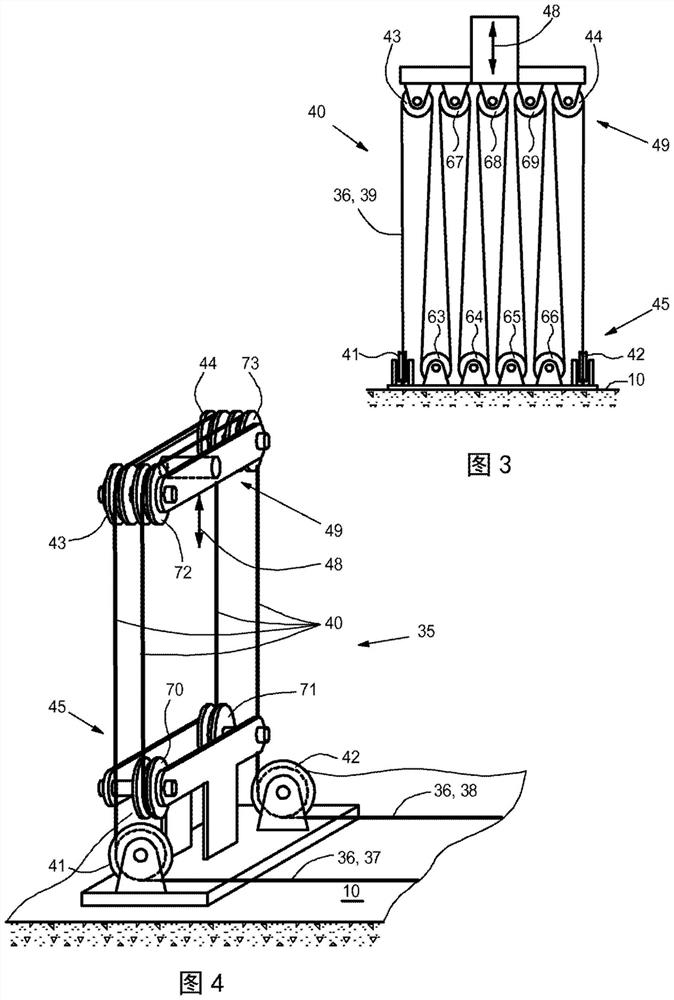

[0038] figure 1 A schematically shows an elevator system 1 installed in an elevator shaft 2 of a building 3 in front view. figure 1 B shows the same elevator system 1 in side view for a better understanding of the cable arrangement shown. With reference to the elevator system 1, a method for building the elevator system 1 will also be described.

[0039] The elevator system 1 has an elevator drive 4 , an elevator car 5 , a counterweight 6 and at least one flexible carrier 7 . The elevator car 5 and the counterweight 6 are guided here along guide rails (not shown). In this embodiment, the elevator system 1 is arranged at least substantially in an elevator shaft 2 . The elevator shaft 2 is delimited here laterally by shaft walls 8 , 9 . The elevator shaft 2 is bounded downwards by a floor 10 . The elevator shaft 2 is basically open upwards during the construction of the elevator system 1 , wherein a suitable cover can be provided. When the building is fully built, the elev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com