Calibration-free method for disassembly and assembly of inertial components of strapdown inertial navigation system

A technology of strapdown inertial navigation and inertial components, which is applied in the field of disassembly and assembly of inertial components of strapdown inertial navigation systems without calibration, can solve problems such as installation errors and the influence of inertial navigation system accuracy, so as to reduce maintenance costs, speed up maintenance efficiency, and improve The effect of repairability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be noted that the embodiments are descriptive, not restrictive, and cannot limit the protection scope of the present invention.

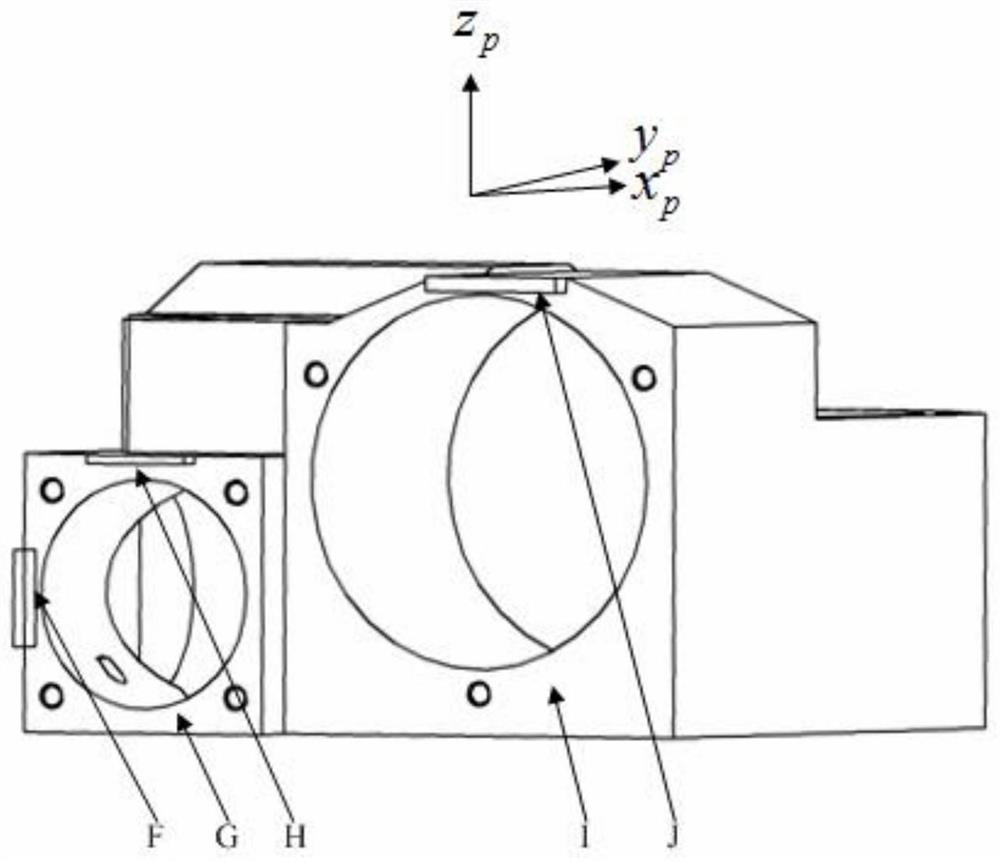

[0103] A calibration-free method for disassembling and assembling an inertial component of a strapdown inertial navigation system, characterized in that it comprises the following steps:

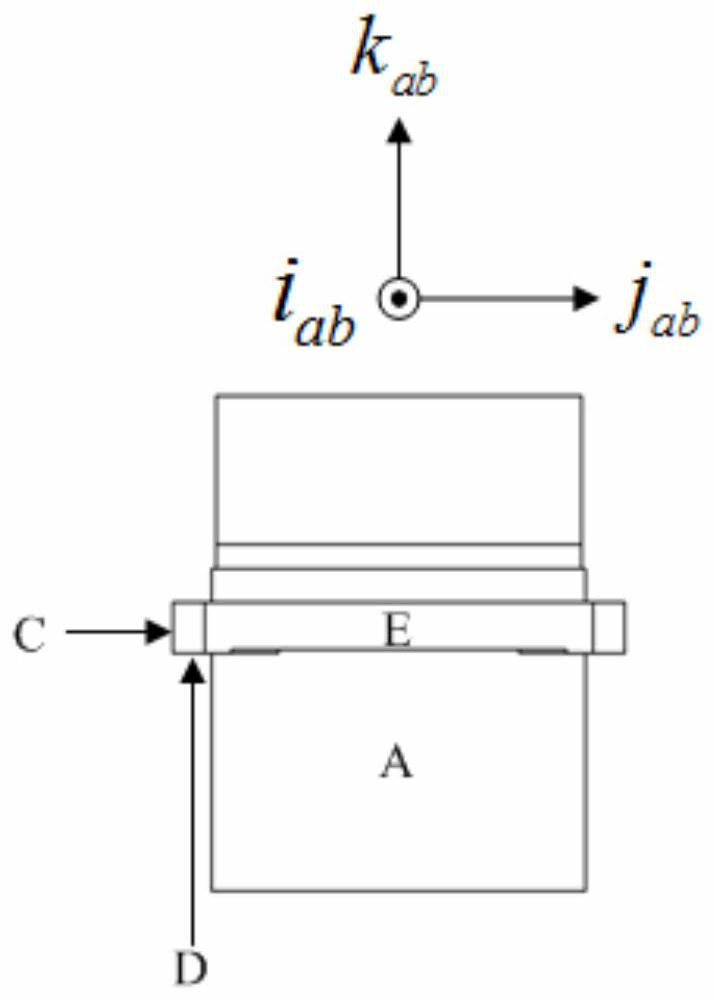

[0104] ⑴, gyroscope 3 degrees of freedom installation reference design;

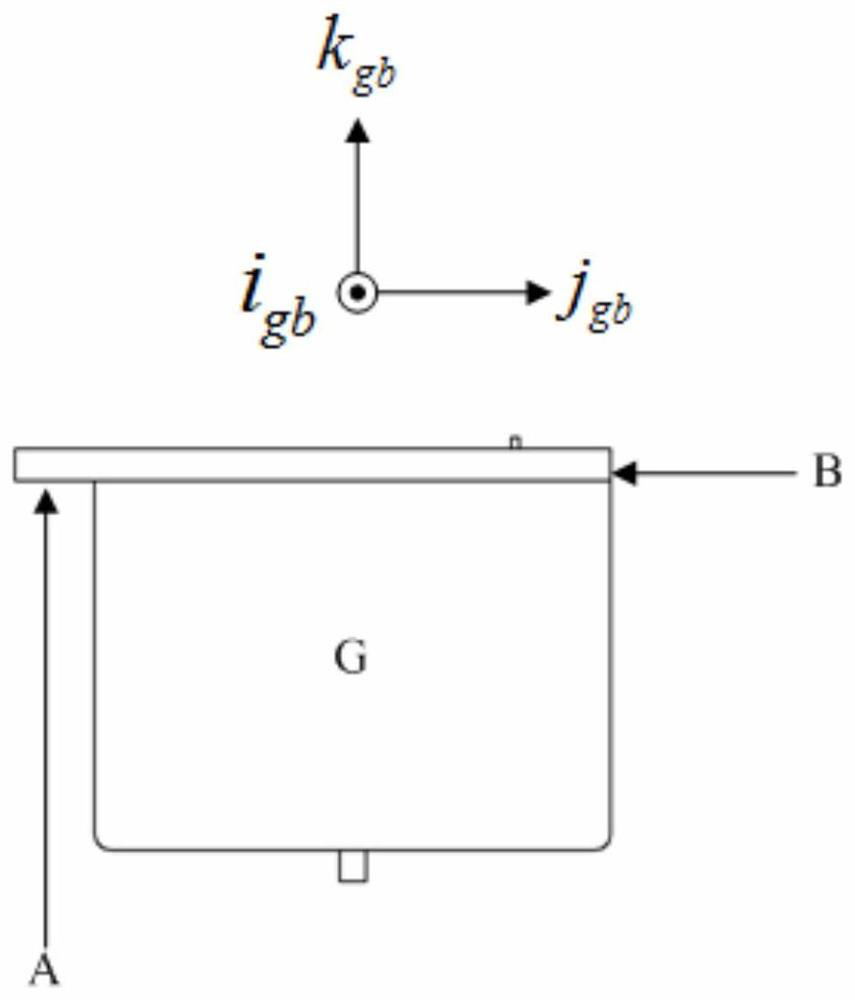

[0105] Establish the gyroscope body coordinate system on the gyroscope, such as figure 1 shown,

[0106] in,

[0107] G stands for gyroscope;

[0108] gb represents the gyroscope body coordinate system;

[0109] p represents the IMU coordinate system;

[0110] i gb , j gb , k gb respectively represent three mutually orthogonal axes on the gyroscope body coordinate system;

[0111] x p , y p ,z p Respectively represent three mutually orthogonal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com