Numerical control gear hobbing machine hob spindle mechanism

A gear hobbing machine and spindle technology, which is applied in the field of gear processing machine tools, can solve the problems of relatively high rigidity and speed requirements of the spindle, failure to satisfy automation, and complex structure, and achieve the requirements of automatic production, simple structure, and reduced production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

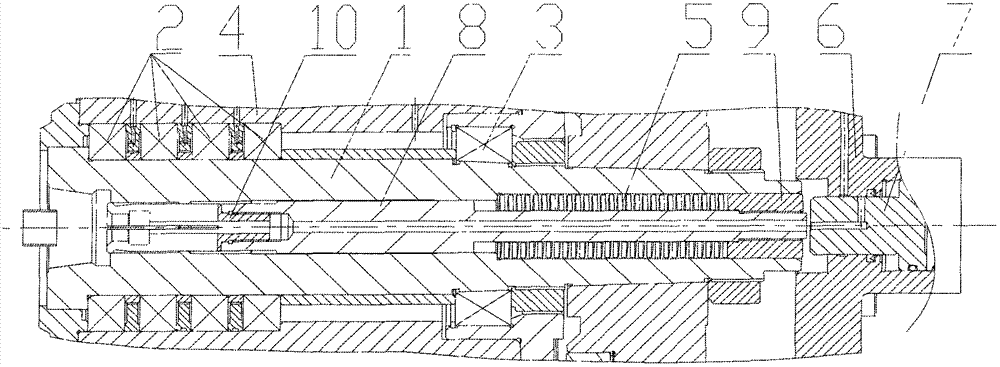

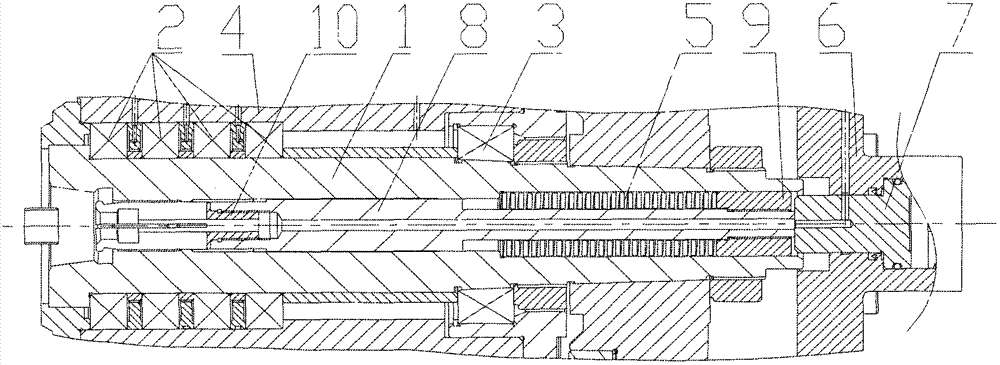

[0010] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] The mechanism has an oil mist lubrication interface, an operating gas circuit interface and an operating oil circuit interface.

[0012] Such as Figure 1-2 The present invention shown includes: the pull claw 10 is fixed on the pull rod 8, the nut 9 locks the rear end of the mold spring 5 sleeved on the pull rod 8 and can adjust the spring pressure, and the front end of the mold spring 5 is stuck on the shoulder of the inner hole of the main shaft 1 The main shaft 1 is fixed on the main shaft box 4 through the angular contact bearing 2 of the front journal and the double-row cylindrical roller bearing 3 of the rear journal, and the piston 7 at the rear end of the main shaft 1 is connected to the cylinder housing 6 . There is an oil mist lubrication channel on the spindle box 4, the pull rod 8 and the pull claw 10 are hollow structures,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com