Trailing edge flap control method for relieving load fluctuation of wind wheel of floating type wind turbine

A control method and technology of wind turbines, applied in the control of wind turbines, engine control, wind turbines, etc., to achieve the effects of improving quality, reducing fatigue, and reducing wind wheel load fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

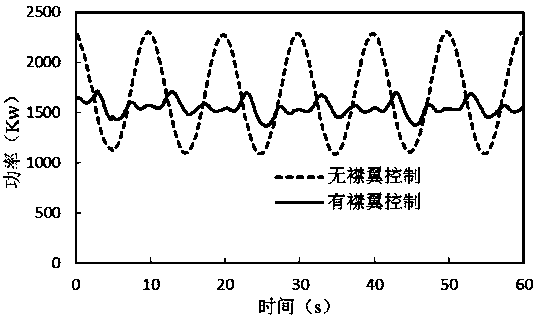

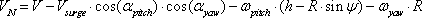

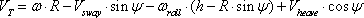

[0026] This method is used to slow down the load fluctuation of the wind turbine caused by the movement of the floating wind turbine platform, so the main input of the control program is the six degrees of freedom of the floating platform (including surge, sway, and heave) measured by the inertial measurement unit. , pitch, roll, and yaw) motion data, and then calculate the relative velocity of the airflow at the blade flap position, including the axial relative velocity and the tangential relative velocity, by setting the flap deflection angle relative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com