Sand flushing method

A technology for sand flushing and well drilling, which is applied in wellbore flushing, earthwork drilling, wellbore/well components, etc. It can solve the problems of increasing the workload and labor intensity of operating workers, affecting production timeliness, etc., and reducing tripping operations , Improve production efficiency and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

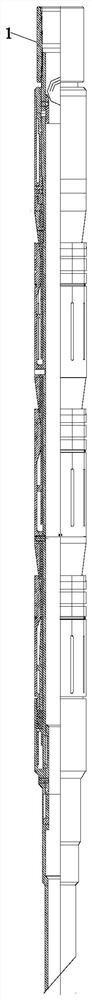

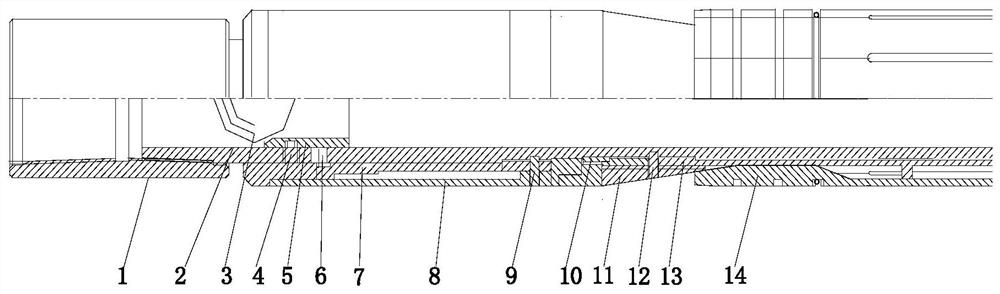

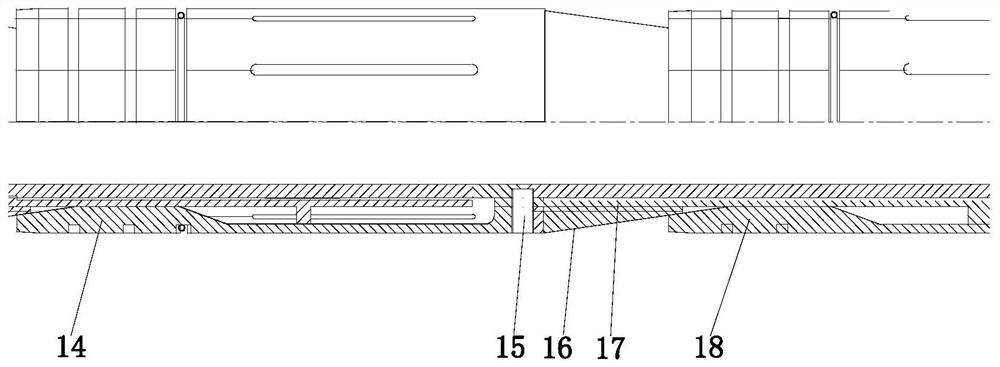

[0017] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a sand flushing well drilling device, which includes a center pipe 2 , a pressing drive assembly, a frustum body 11 and a reducing sleeve 14 . The pressing drive assembly is arranged on the central tube 2 and can move along the axis of the central tube 2 . The frustum body 11 is sleeved on the central tube 2. The frustum body 11 has a large-diameter end and a small-diameter section. The large-diameter end is connected to one end of the pressing drive assembly. Axis direction movement. The reducing sleeve 14 is sleeved outside the central tube 2 and located at the small diameter end of the frustum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com