Lifting leveling guide rail and leveling process utilizing same

A leveling guide rail and process technology, which is applied in the field of lifting leveling guide rail and leveling technology using lifting leveling guide rail, can solve the problems of inconsistent thickness, low ground flatness, slow construction progress, etc., and achieve easy control of thickness and quantity, hollowing The effect of low efficiency and fast construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

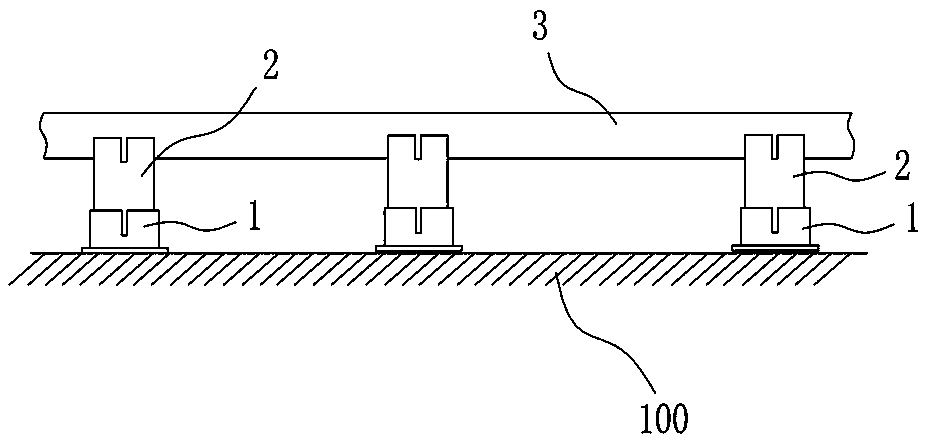

[0035] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0036] Such as Figure 1 to Figure 5 As shown, the lifting leveling guide rail of the present invention includes:

[0037] Base 1, the lower end of the base 1 has a positioning plate 11, the positioning plate 11 is provided with a positioning hole 12, the upper end of the base 1 has a mounting sleeve 13, the base is integrally formed, the material of the base is preferably plastic material, and the diameter of the positioning hole is preferably 3-8mm;

[0038] Adjustment screw 2, the lower end of the adjustment screw 2 is screwed to the installation sleeve 13, and the upper end of the adjustment screw 2 is provided with a "ten"-shaped groove 21; the adjustment screw 2 has several height specifications to adjust the leveling guide rail 3 The height distance from the ground / floor 100 is integrally formed by ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com