Helicopter type rotorcraft

A technology for rotorcraft and rotors, applied in the field of rotorcraft, can solve the problems of limited use range of rotorcraft and large area required for takeoff of rotorcraft, and achieve the effects of reducing flight energy consumption, increasing use range and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings. Embodiments of the present invention include, but are not limited to, the following examples.

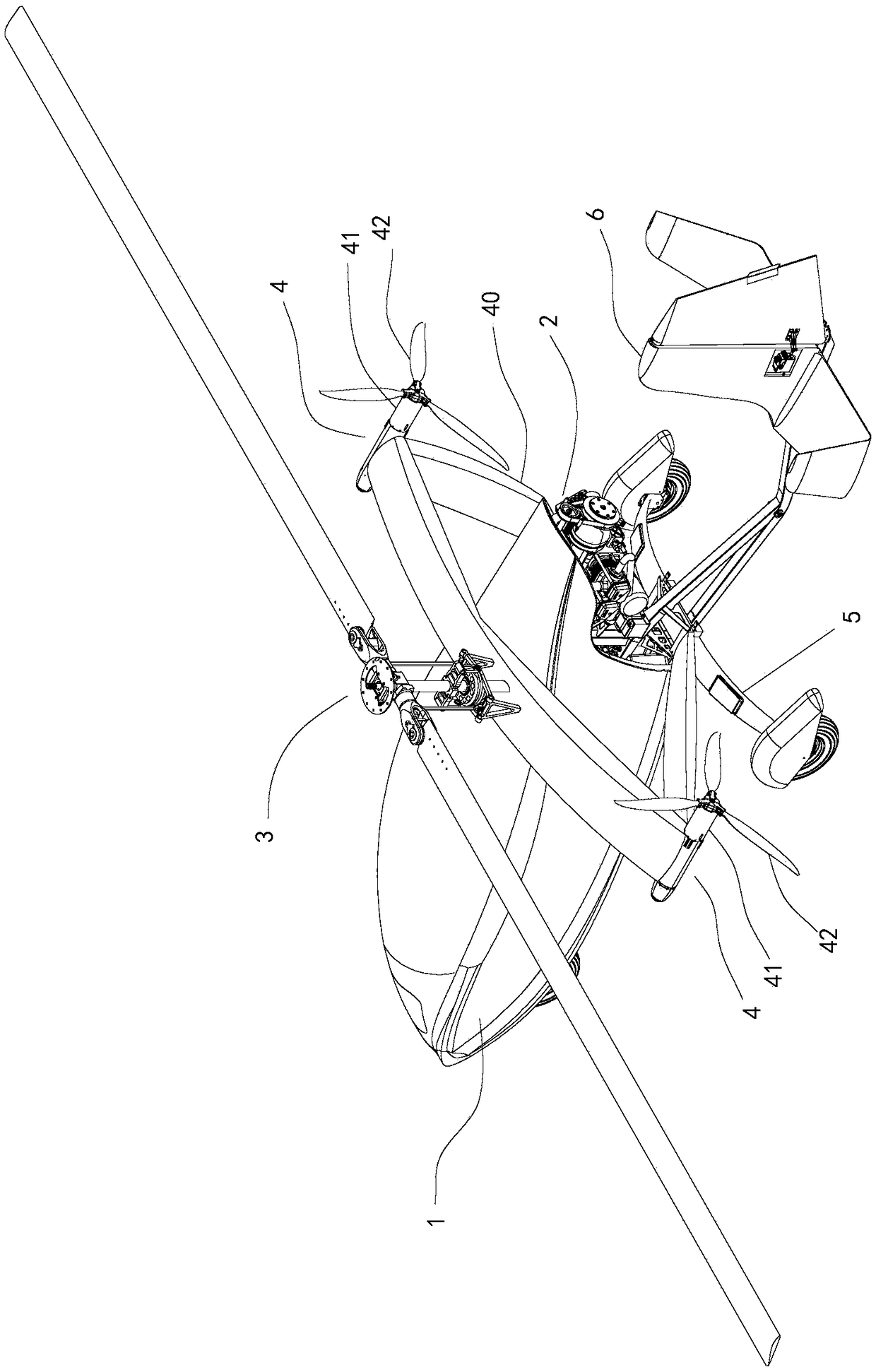

[0016] The concrete structure of helicopter rotorcraft of the present invention is as figure 1 , figure 2 As shown, it is mainly composed of fuselage 1, engine 2, main rotor mechanism 3, propulsion mechanism 4, landing gear 5 and tail rudder 6. The main rotor mechanism 3 is installed on the top of the fuselage 1, which includes a main shaft 30, The upper end of the main shaft 30 is equipped with the main rotor 32 through the variable pitch rotor head assembly, and the lower end of the main shaft 20 is connected with the main reduction box of the engine 2 through the main clutch 37. The rotor nose 31 at the upper end, a pair of main rotors 32 are rotatably assembled on the rotor nose 31, a swash plate assembly 33 is installed below the rotor nose 31, and the bottom of the sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com