Central integrated electric drive axle assembly with two motors and two speed reducers

A technology of double speed reducer and speed reducer, applied in the direction of electric power unit, power unit, control device, etc., can solve the problem of low maximum speed, system weight, system cost impact is not easy to achieve, structural form and performance can not meet the application of pure electric truck and other problems to achieve the effect of reducing weight and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the drawings:

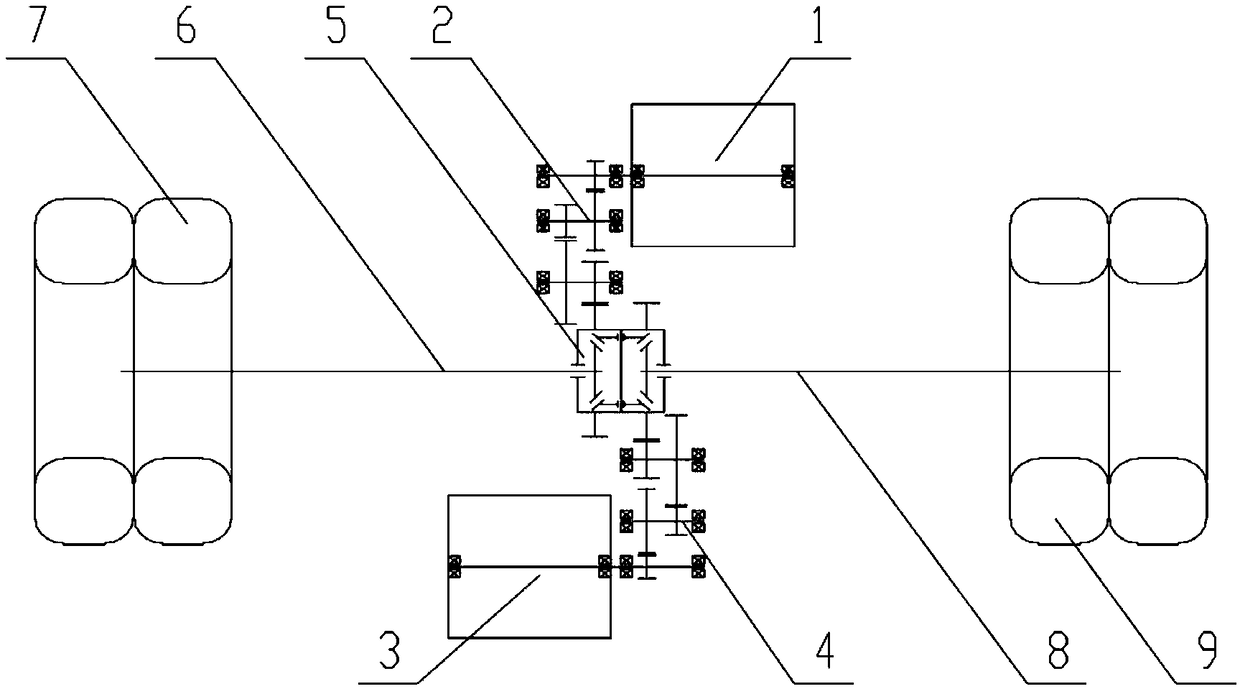

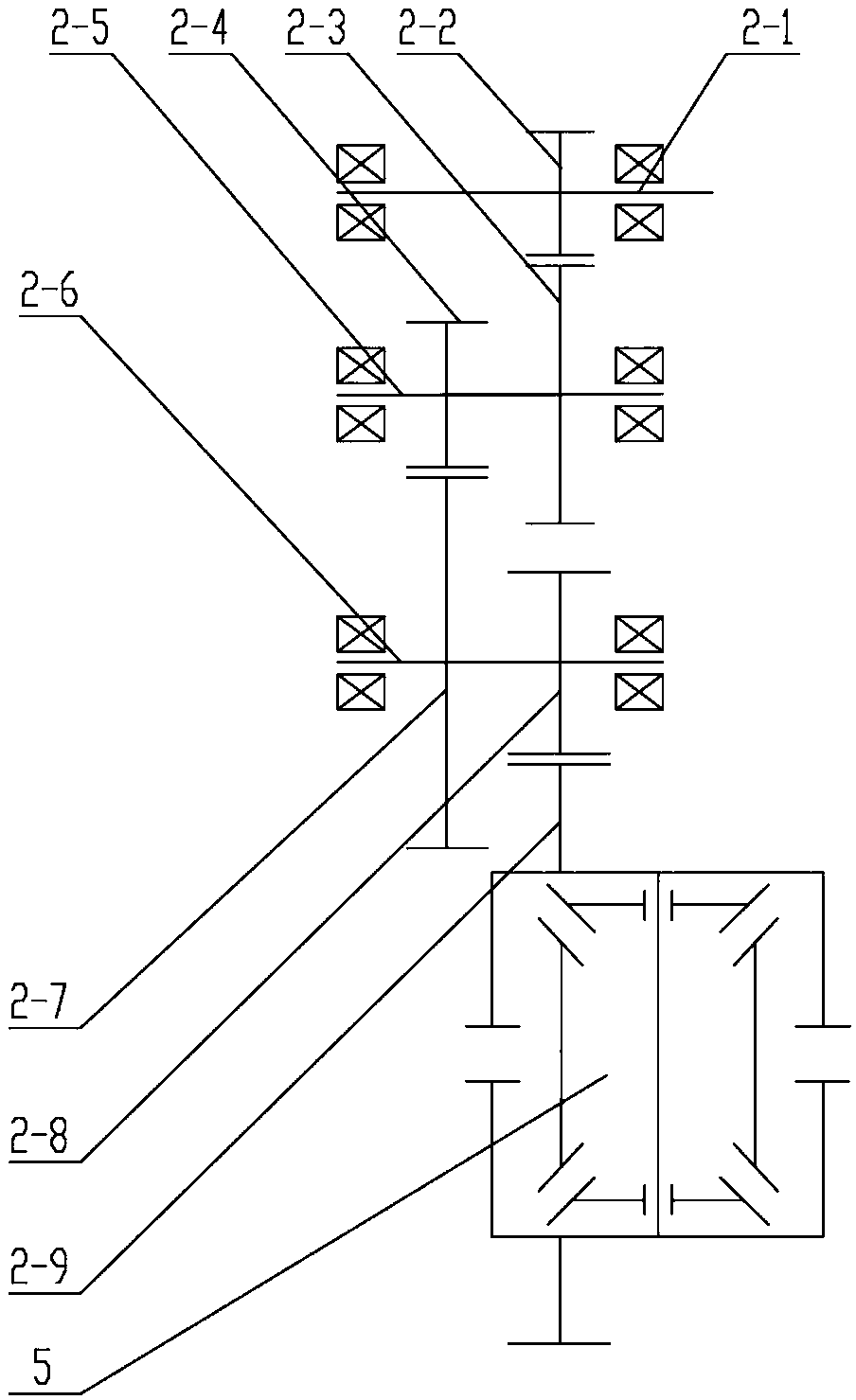

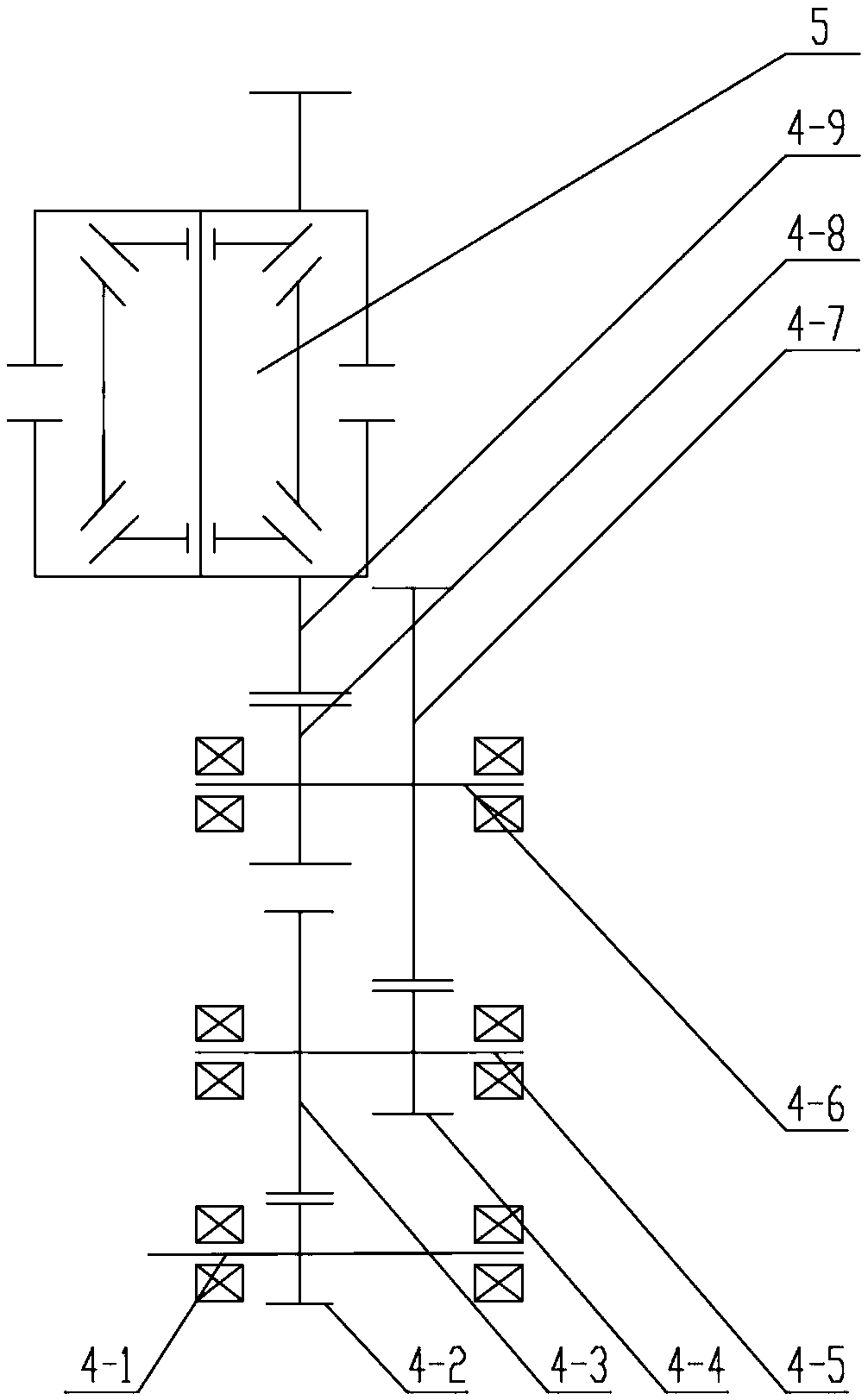

[0019] Such as figure 1 Shown: The present invention provides a centrally integrated dual-motor dual-reducer electric drive axle assembly, including an axle housing, a first drive motor 1, a first reducer assembly 2, a second drive motor 3, and a second reduction gear Gear assembly 4, bevel gear differential assembly 5, left half shaft 6, left wheel 7, right half shaft 8, right wheel 9; bevel gear differential assembly 5 is arranged in the axle housing, and the left wheel 7 is connected to one end of the left half shaft 6, the other end of the left half shaft 6 is fixedly connected to the left half shaft gear in the bevel gear differential assembly 5, the right wheel 9 is connected to one end of the right half shaft 8, and the right half The other end of the shaft 8 is fixedly connected with the right side gear in the bevel gear differential assembly 5, wherein the first reducer ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com