Oxygen uptake type casting polypropylene high-temperature digestion film

A technology of casting polypropylene and high-temperature cooking, applied in the field of plastic films, can solve the problems of increasing oxygen concentration, inability to completely eliminate it, and affecting the shelf life of food.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

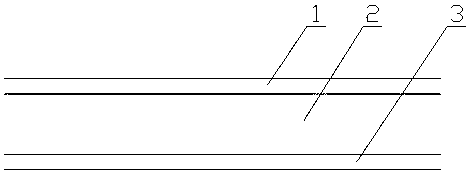

[0010] The specific embodiment of the present invention will be described below in conjunction with accompanying drawing, as figure 1 Shown: an oxygen-absorbing cast polypropylene high-temperature retort film, which is a three-layer structure. The oxygen-absorbing layer 1 contains 20-60% block copolymerized polypropylene and 40-80% iron-containing oxygen-absorbing masterbatch, and the middle layer 2 contains 85-98% block copolymerized polypropylene and 2- 15% polyolefin elastomer, heat seal layer 3 contains 78-96% block copolymer polypropylene, 2-15% polyolefin elastomer and 2-7% silicone smooth masterbatch, the above ratios are all is a mass percentage, wherein the thickness of the oxygen-absorbing layer 1 is greater than 20 microns, and the thickness ratio of the middle layer 2 and the heat-sealing layer 3 is 2-4:1.

[0011] The polypropylene film of the embodiment of the present invention is mainly used in the field of food packaging. The food packaging bag made of this p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com