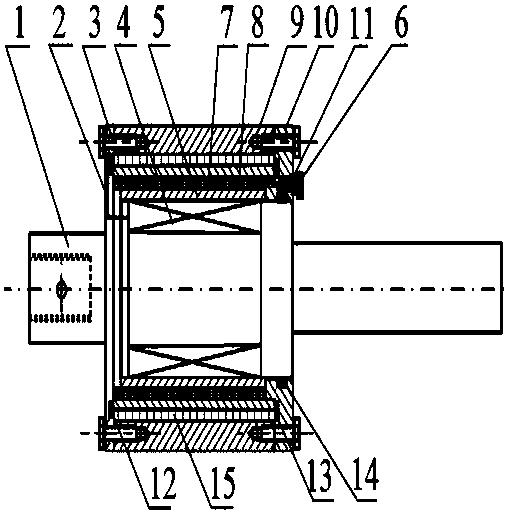

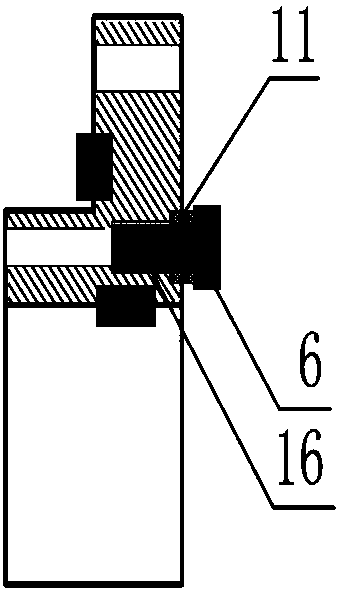

Damping cutter bar for turning coarse-pitch threads

A large pitch and thread technology, applied in the direction of thread cutting tools, metal processing equipment, tangent devices, etc., can solve the problems affecting the machining accuracy of the surface quality of workpieces, achieve the suppression of cutting chatter, facilitate manufacturing, processing and installation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

[0022] The cutting chatter is often accompanied by the occurrence of cutting chatter, which will seriously affect the surface morphology and cutting precision of the workpiece. Especially in the process of turning large-pitch threads, due to the large cutting force generated by high-feed cutting, cutting chatter is also large, which seriously affects the surface quality of large-pitch thread parts. Aiming at the harm caused by this kind of vibration, scholars at home and abroad have done a lot of research on the mechanism of vibration generation and vibration suppression. Vibration suppression methods are mainly divided into three categories, active control, passive control and semi-active control. Among them, active control to suppress vibration has relatively high requirements on detection accuracy and control system, and often requires additional components such as power supply, sensors, and actuators, and has a complex structure; pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com