A kind of automatic coating unit and method of elastic body structure functional coating

An automatic painting and coating technology, applied in spraying devices, spray booths, etc., can solve problems such as affecting the utilization rate of spray booths, spraying workpieces occupying spraying stations, and long coating curing cycles, so as to solve problems of productivity and automation. , Reduce curing waiting time, high quality and rapid construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

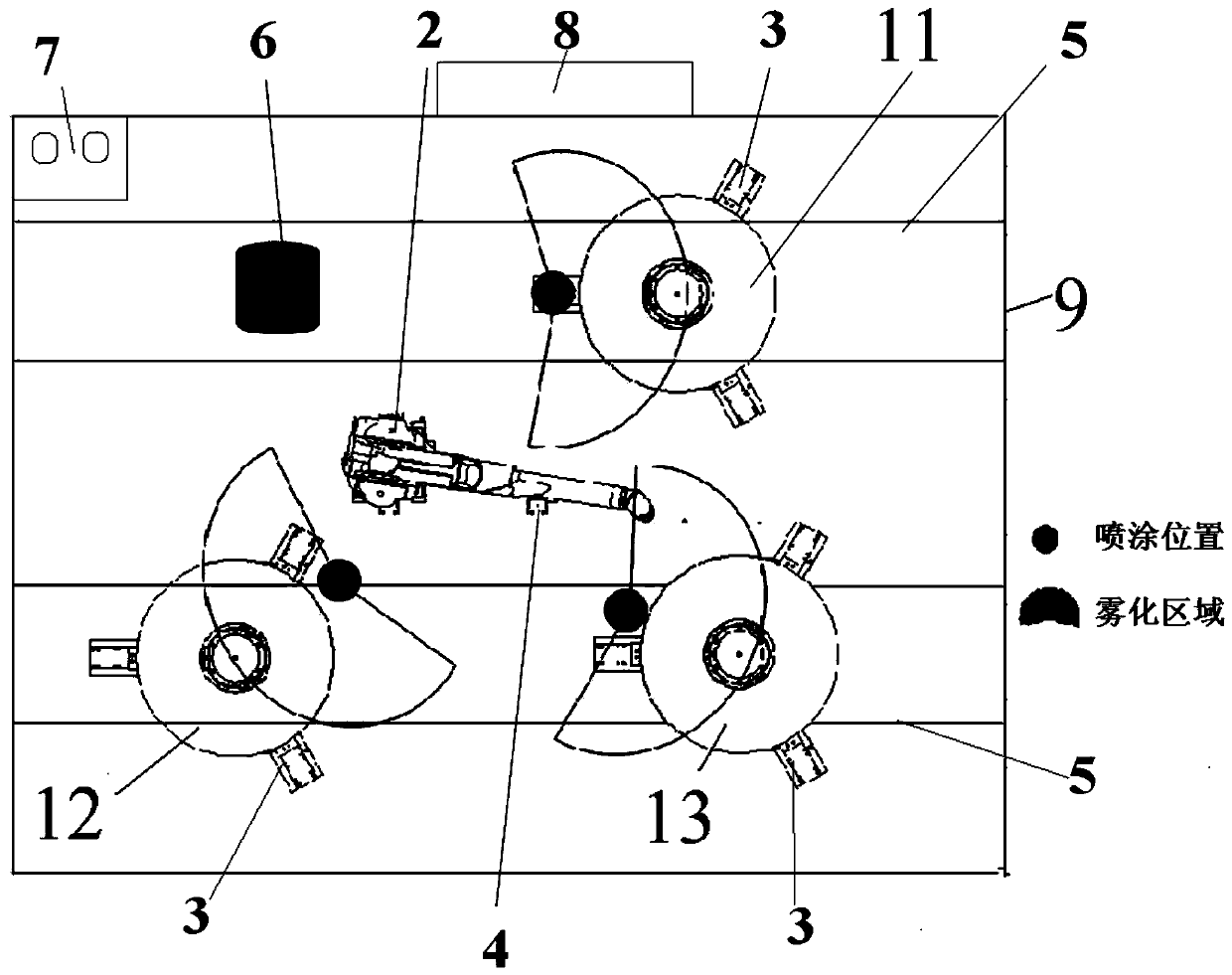

[0048] Such as figure 1 As shown, an automatic coating unit for projectile structure functional coating, the coating unit includes a spraying robot arm 2, three turntables 3, a laser scanning thickness measuring device 4, two rails 5, a waste liquid bucket 6, a feeding System 7, central control system 8 and spray booth 9; two tracks 5 are respectively the first track and the second track, and three turntables 3 are respectively the first turntable, the second turntable and the third turntable;

[0049] The spraying robot arm 2, three turntables 3, laser scanning thickness measuring device 4, two rails 5, waste liquid bucket 6, and feeding system 7 are installed in the spray booth 9, and the central control system 8 is installed in the spray booth 9 outside;

[0050] The first track and the second track are installed on the ground in the spray booth 9, and the distance between the first track and the second track is 1.5-2 times the diameter of the largest workpiece to be spray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com