Multifunctional stuffing mixing robot

A multifunctional and robotic technology, applied in mixers, chemical instruments and methods, dissolution, etc., can solve problems such as troublesome raw materials for meatballs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

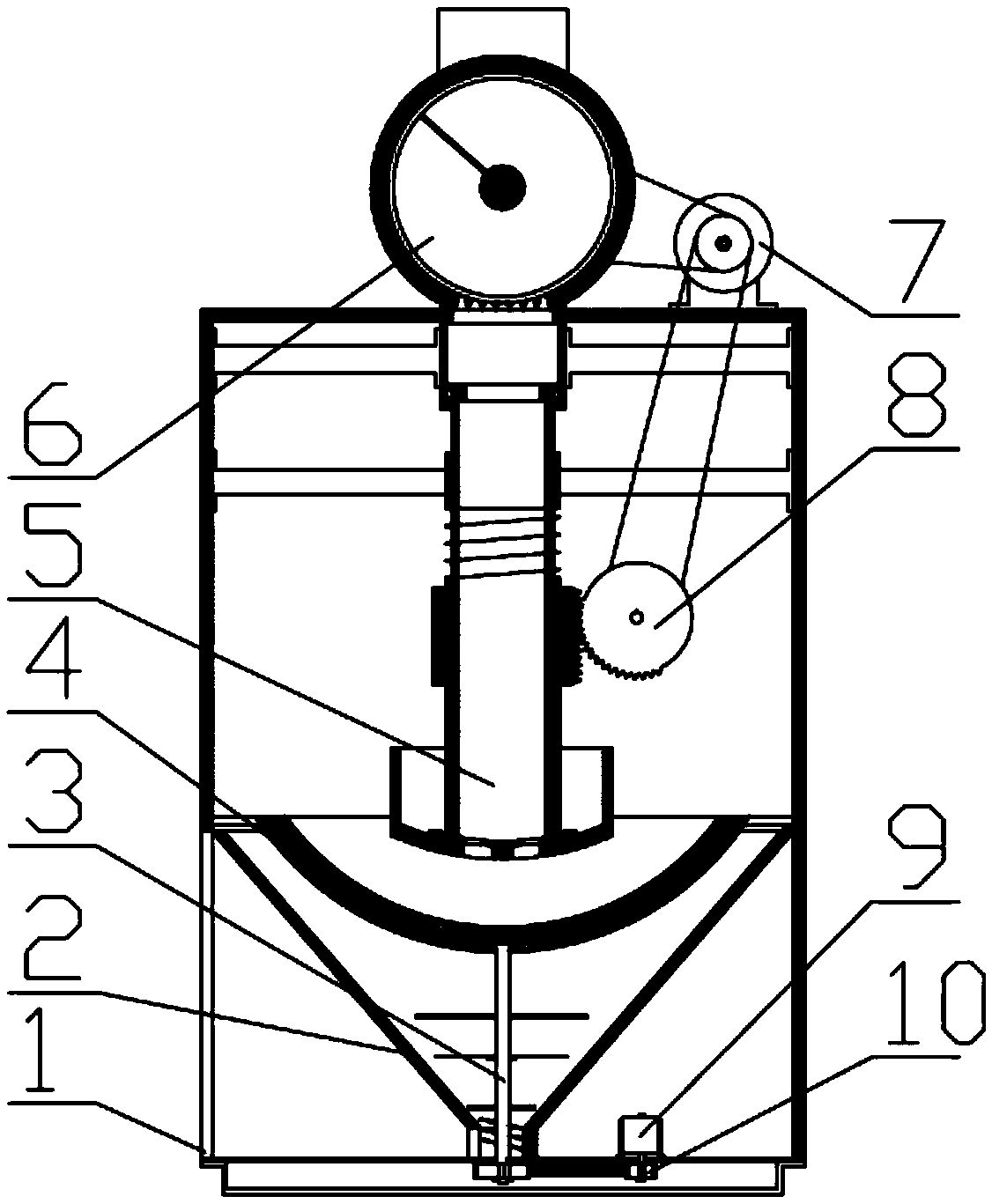

[0036] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, and 13 illustrate this embodiment. The present invention relates to a crushing and stirring device, more specifically a multifunctional stuffing mixing robot including installation Support box 1, stirring funnel device 2, stirring device 3, impact shell 4, impact device 5, crushing device 6, crushing power device 7, transmission lifting device 8, stirring power device 9, power transmission triangle belt 10, can be The stuffing or balls to be made are first crushed by the crushing device into a size that can leak out from the small hole under the crushing shell, and then repeatedly impacted by the impact device under the action of the power device, and then overflow under the accumulation of impact stuffing Fall into the stirring device, start stirring in the forward direction, and discharge the stirred stuffing in the reverse direction.

[0037] The installation supporting box 1 is composed of box body 1-1,...

specific Embodiment approach 2

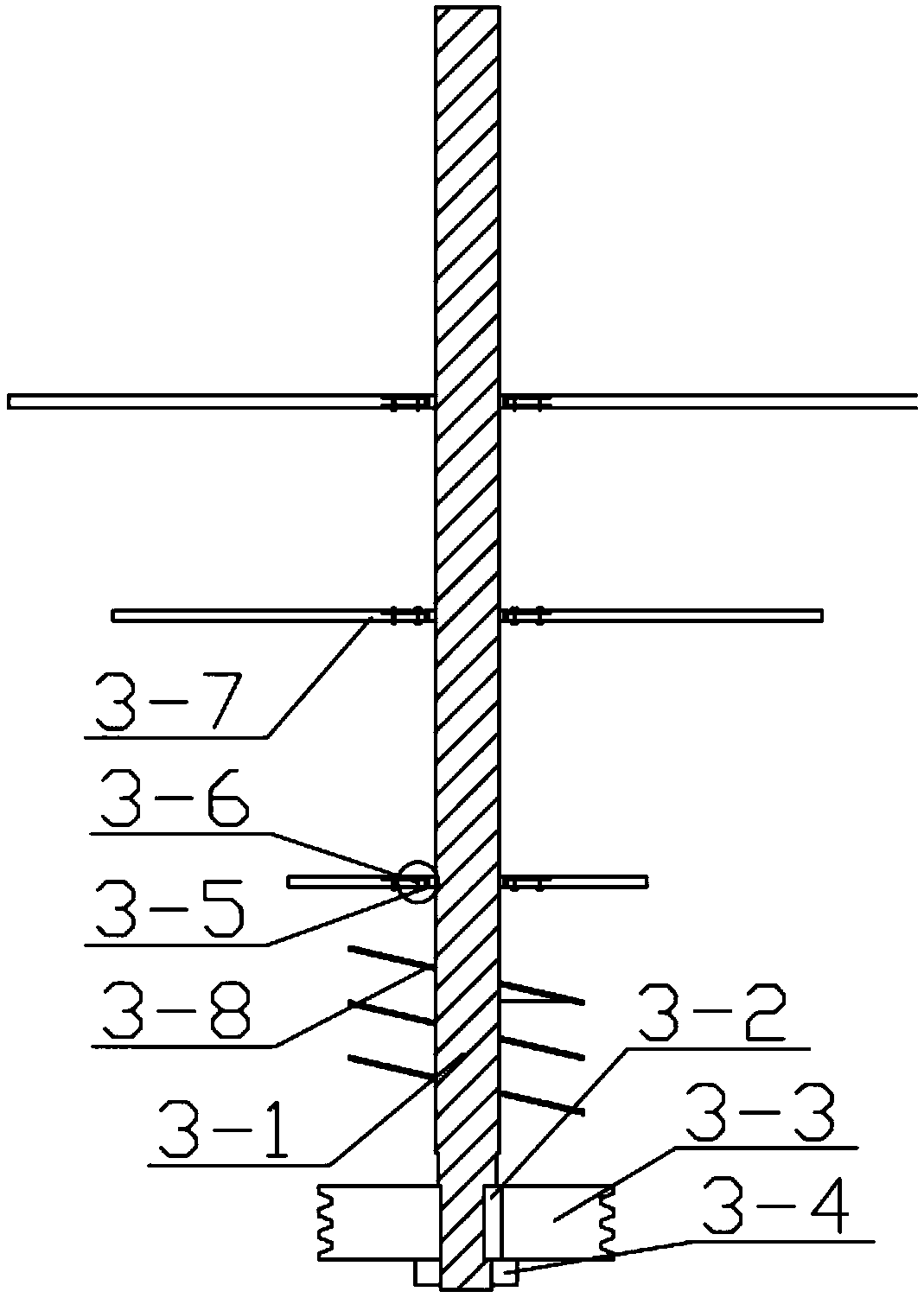

[0049] Combine below figure 1 , 2 . -5 and stirring fan blades 3-7 all have twelve, but the lengths of stirring fan blades 3-7 are different, bolt group 3-6 has twenty-four, and the rotation control of stirring fan blades 3-7 cannot material.

specific Embodiment approach 3

[0050]Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, and 13 illustrate this embodiment, and this embodiment will further describe Embodiment 1. The composition is roughly the same, so only one is illustrated above.

[0051] The working principle of the present invention is:

[0052] The working principle of a multifunctional stuffing mixing robot is, before processing, first check whether the cooperation between the devices is normal, avoid the danger during processing, start the device, rotate the crushing power device 7 and the stirring power device 9, and turn the required processing The material is placed in the feeding hole 6-2 of the crushing device 6, the pulley 7-4 of the crushing power device 7 drives the rotation of the crushing drive pulley 6-3-3 through the V-belt, and the crushing drive pulley 6-3-3 drives the rotation The rotation of the shaft 6-3-1, the rotation shaft 6-3-1 drives the rotation of the crushing rotary plate 6-3-2, the crushing ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com