Near-ship-end Antarctic krill continuous pumping fishing system

An Antarctic krill and pump suction technology, which is applied in fishing, fishing nets, applications, etc., can solve problems such as reducing life expectancy, affecting ship stability, and restricting trawling time, so as to reduce capacity dependence and demand, save ship layout space, The effect of reducing the labor load of the crew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

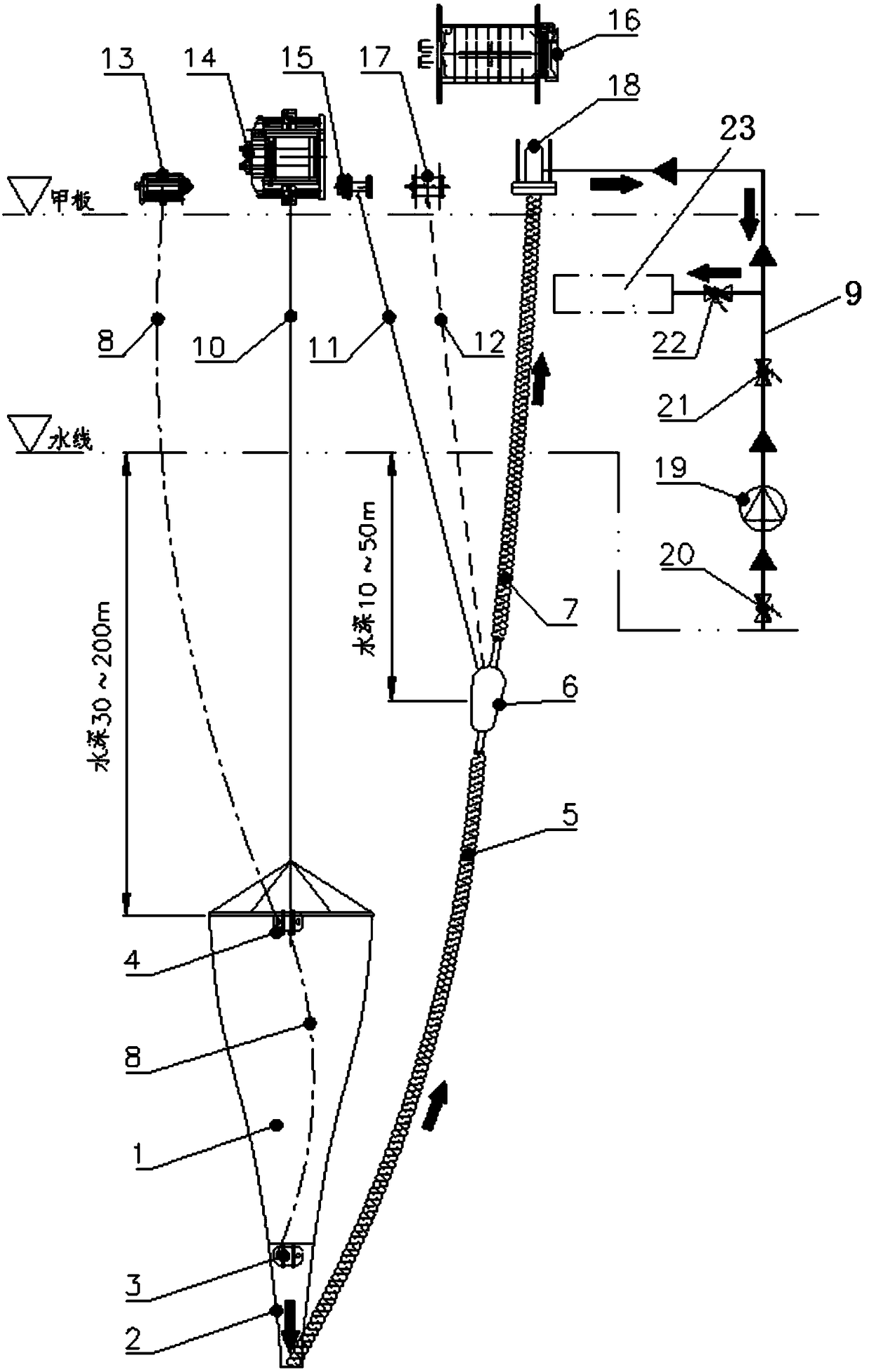

[0035] see figure 1 As shown, the present invention discloses a continuous pump suction fishing system for Antarctic krill near the ship, including a krill net 1, a mesh bag 2, a shrimp suction pump 6, a drag wire 11, a backwash system, a first sensor 3 and a second sensor 4.

[0036] The krill net 1 is specially woven and designed to catch Antarctic krill. It is divided into a horizontal bar krill net and a mesh plate krill net. The net port of the krill net 1 is connected with the trawl steel wire 10, and the trawl steel wire 10 can be retracted. On the trawl winch 14.

[0037] The net capsule 2 is arranged at the end of the krill net 1 and adopts a weaving design.

[0038] The shrimp suction pump 6 is a centrifugal pump. The design of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com