Sensor for monitoring temperature and vibration of rotating body

A sensor and body temperature technology, applied in the mechanical field, achieves the effect of reducing volume, increasing economic and social benefits, and avoiding traffic safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

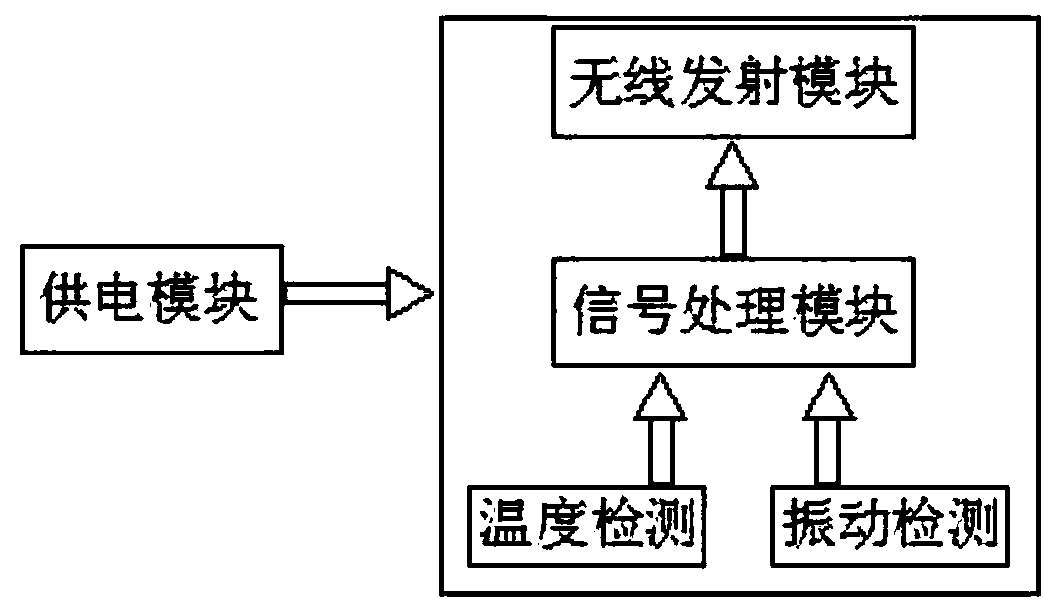

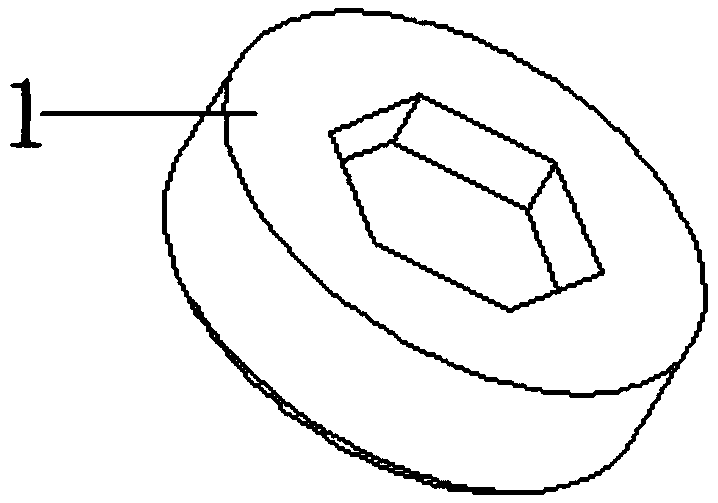

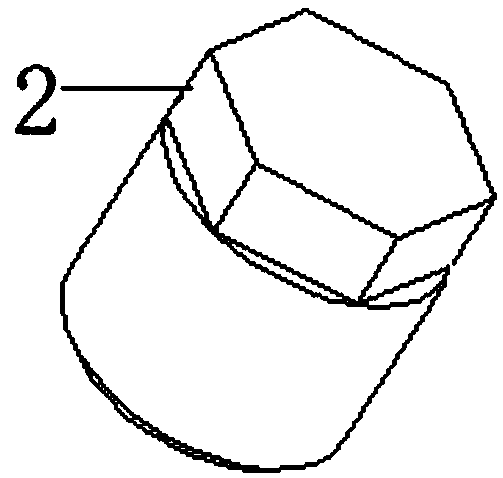

[0029] Such as Figure 1-3 As shown, this embodiment provides a miniature sensor with an inner hexagon, an outer hexagon at the upper end, and a cylinder at the lower end; of course, there are other shapes. This type of sensor integrates temperature detection, vibration detection, signal processing modules, and power supply. Modules, wireless transmission and other modules.

[0030] The external packaging shell of the sensor can be made of metal or non-metallic material according to the requirements, and can be assembled with the rotating body through threads, interference, riveting, etc.; the sensor and the rotating body can be sealed with sealant or sealing ring to ensure Meet the waterproof and dustproof level requirements.

[0031] The power supply module provides electric energy for the sensor, and the temperature detection and vibration detection transmit the detected signal to the signal processing module. The signal processing module filters and amplifies the signal, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com