An adjustable assembly structure and assembly method of a welded ball net frame

A technology of welding balls and grids, which is applied in the direction of special structures, building components, building structures, etc., can solve the problems of high cost of labor and measures, low utilization rate of tooling measures, and heavy workload, so as to achieve convenient and efficient device adjustment process. The effect of small repetitive workload and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

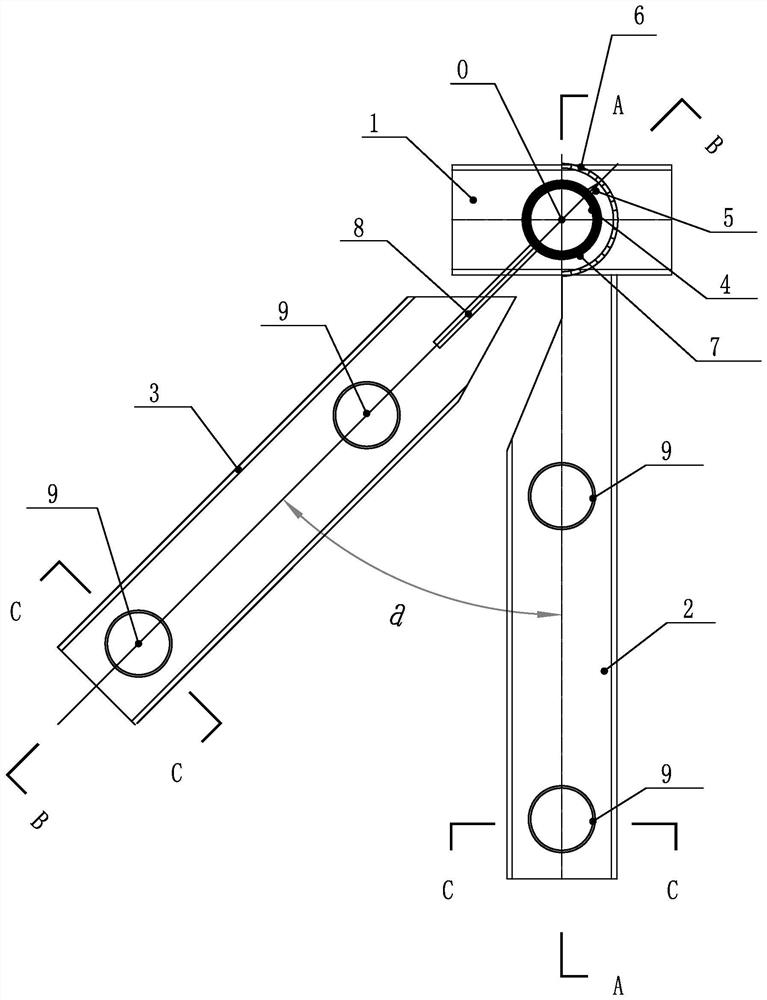

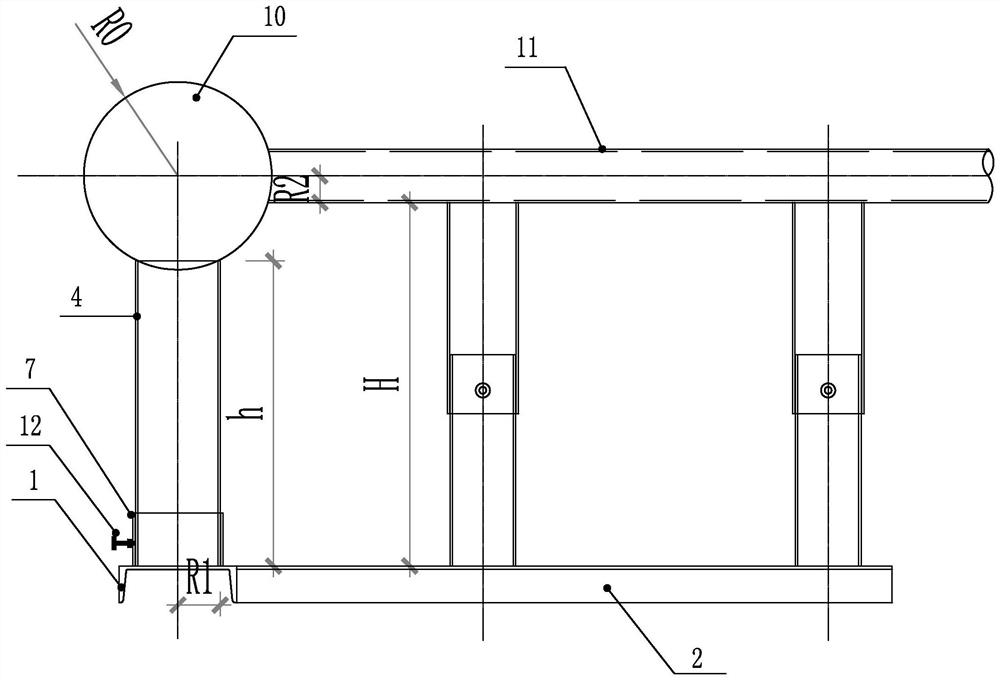

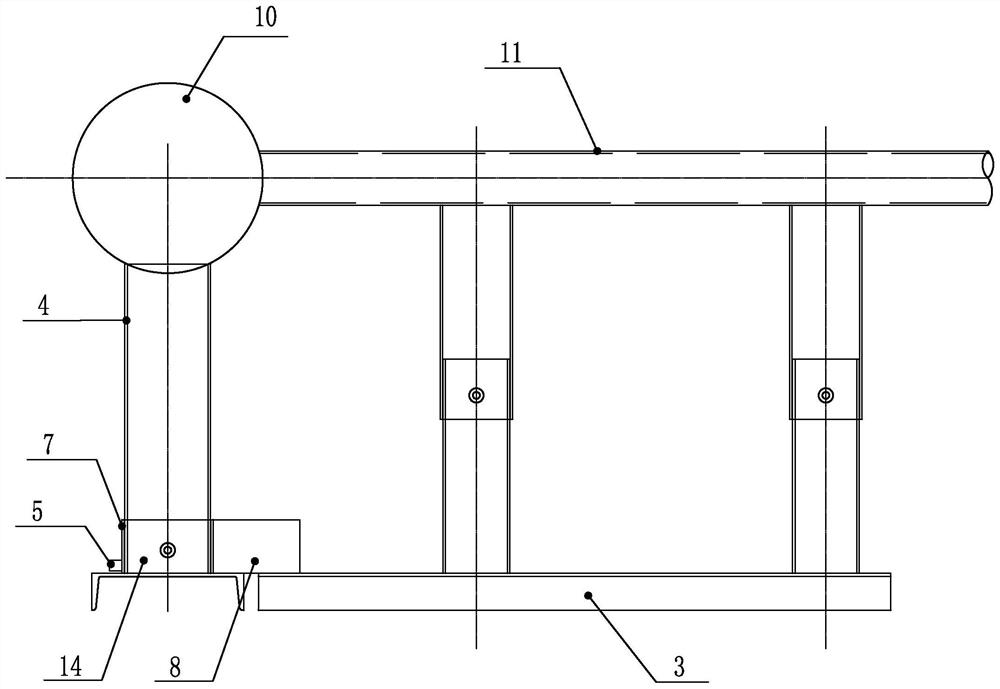

[0024] Below is the combined Figure 1-4 , to further describe in detail the specific implementation of an adjustable assembly structure of a welded ball net frame according to the present invention:

[0025] An adjustable assembly structure of a welded ball net frame, including a base, a support rod fixed on the base and other rotating devices 14; the base includes three channel steel bases with common intersection points, one of which is a short channel steel base 1 , one is a long channel steel base 2, and the other is a movable channel steel base 3; the support bar includes five support round tubes, one is a positioning round tube 4, and the remaining four round tubes are height-adjustable sleeves 9, and the positioning The round pipe 4 is aligned with the intersection center 0 of the short channel steel base 1, the bottom is welded and fixed with the short channel steel base 1, and the bottom is provided with a rotating device 14 connected and fixed with the movable chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com