Variable-diameter reinforcement cage expanded tip anti-floating or compression pile combined with mixing pile or jet grouting pile as well as construction method thereof

A technology for mixing piles and steel cages, which is applied in basic structure engineering, sheet pile walls, buildings, etc., can solve problems such as tension bolts that are not applied to pressure-bearing piles, and achieve the effect of low construction cost and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

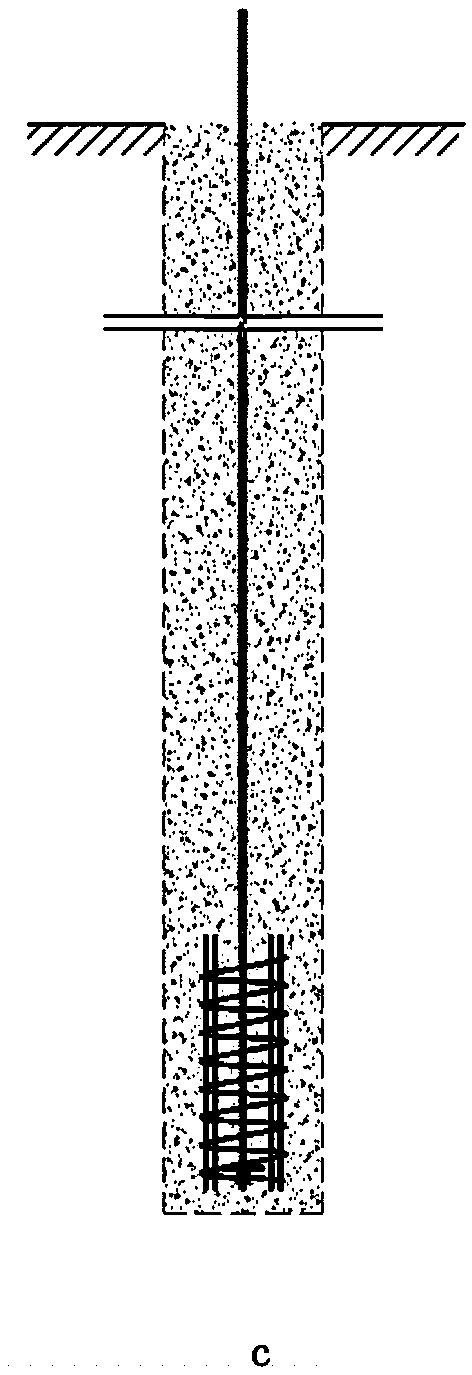

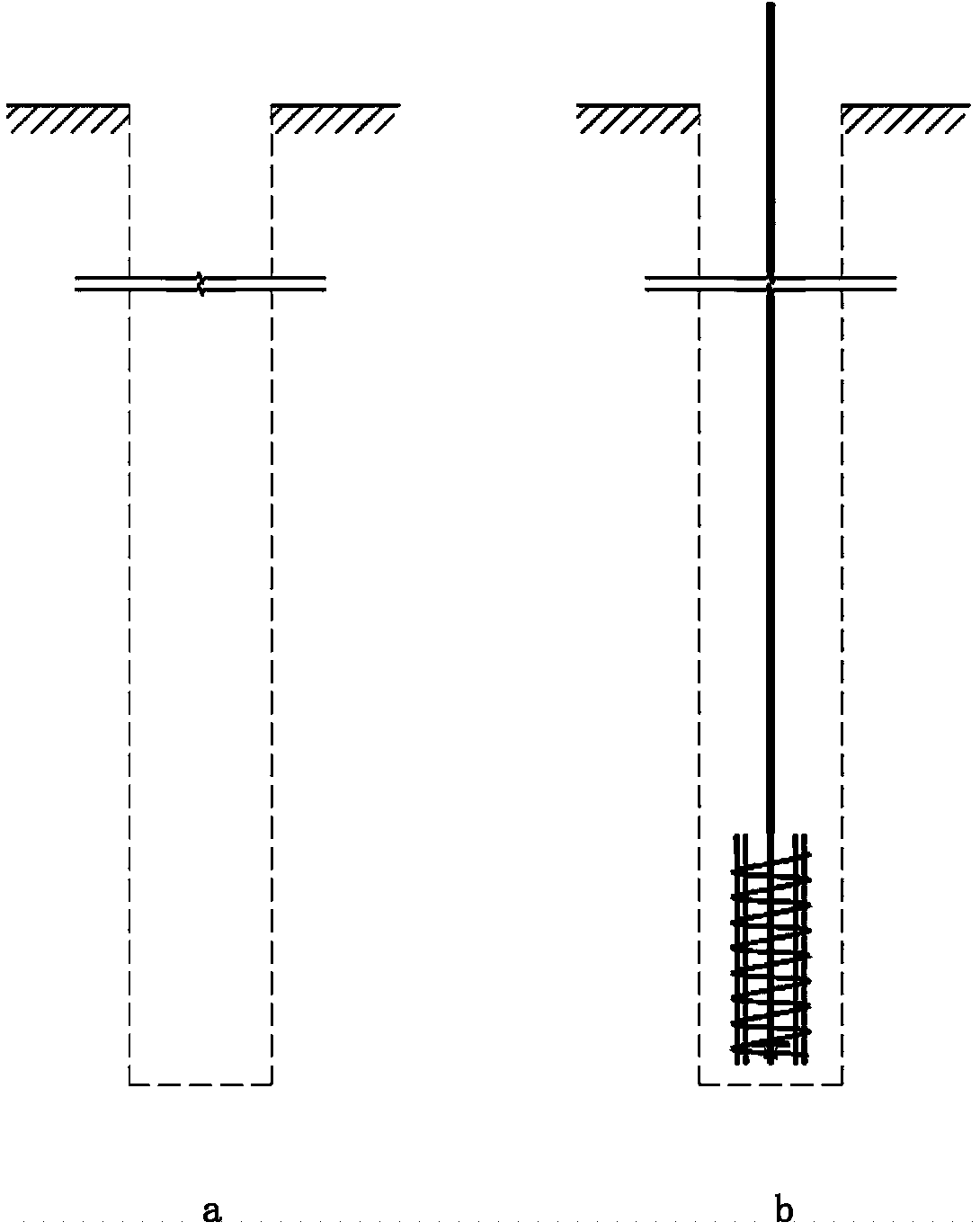

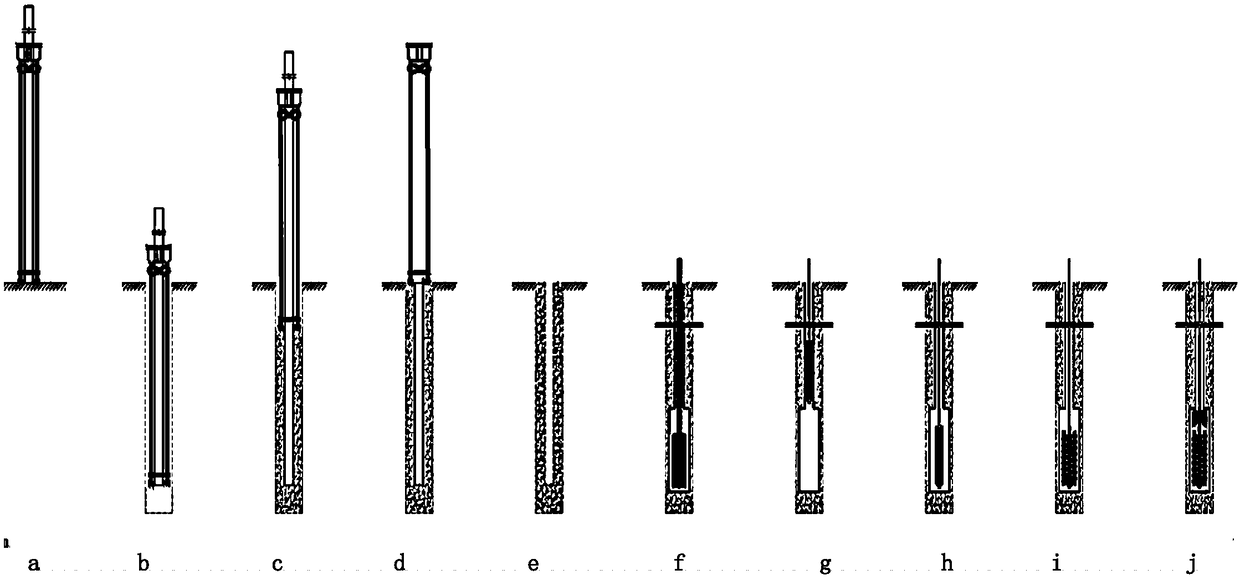

[0020] Embodiment: the variable-diameter reinforced cage enlarged head anchor rod or pressure pile combined with the mixing pile or the rotary grouting pile, in the pile core or pile of the rotary grouting pile or the stirring pile including single pipe, double pipe method, and triple pipe construction The construction holes set at the lap joints or direct drilling, construction through reaming, lowering of variable diameter steel cages and tie rod assemblies, grouting or pouring concrete, composite anchors (or pressure piles) into piles.

[0021] Construction hole or direct drilling → reaming construction → lowering the variable diameter steel cage and tie rod assembly → grouting or pouring concrete → composite anchor (or pressure pile) into piles.

[0022] Variable-diameter reinforced cage expansion head anchor rod combined with mixing pile or rotary grouting pile and construction method, measuring pile position→pile machine in place→construction of mixing pile or high-pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com