Preparation method of graphene-butadiene-acrylonitrile rubber latex matting glove

A technology of graphene and nitrile rubber, which is applied in the direction of gloves, clothing, protective clothing, etc., can solve the problems of wear resistance, puncture resistance, tear resistance, cut resistance defects, high production cost of gloves, etc., and achieve good effect of grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

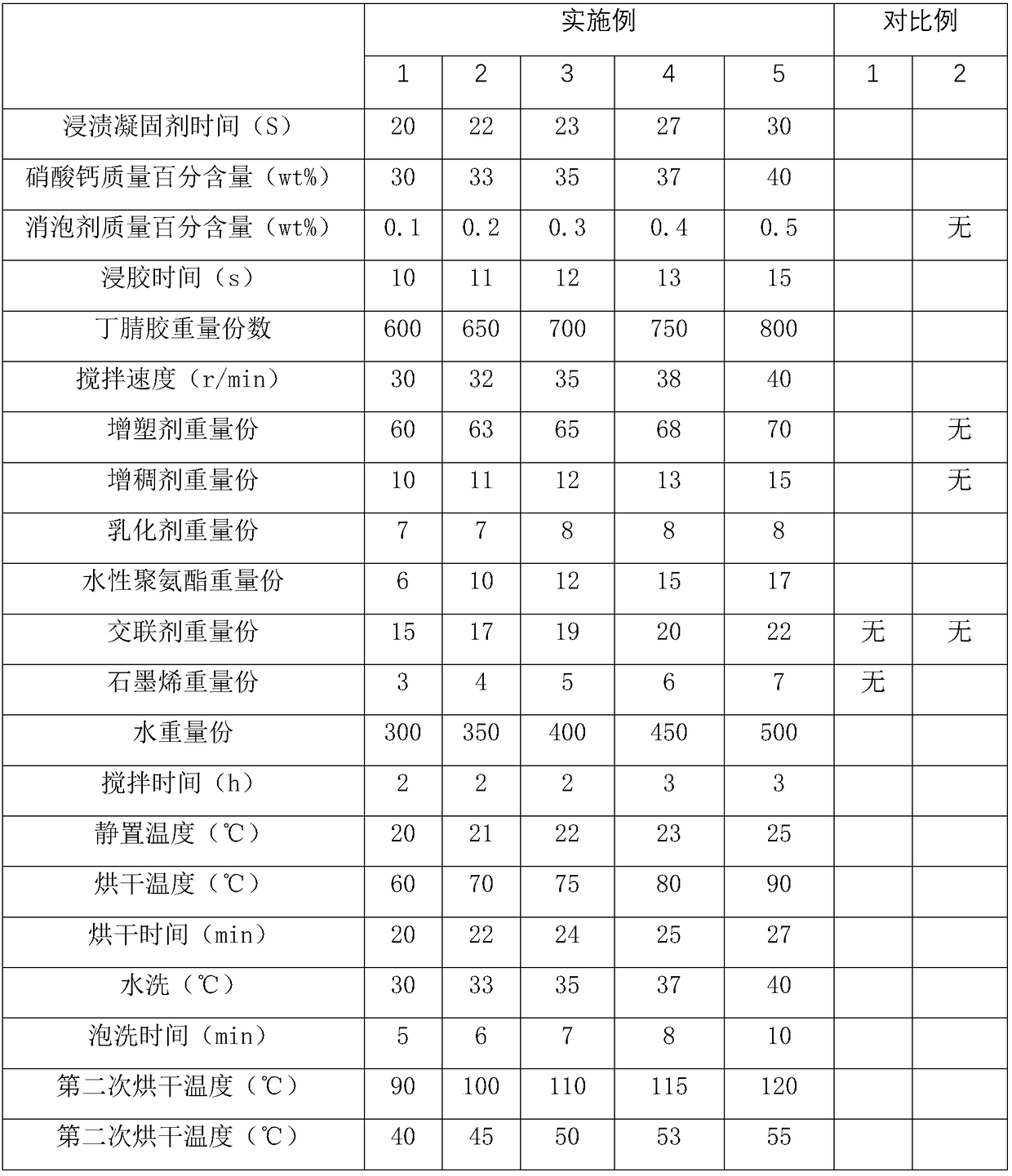

[0037] The specific embodiment part of the present invention provides a kind of preparation method of graphene-nitrile latex scrub gloves, described method comprises the steps:

[0038] 1. Set liner: Put the glove liner on the hand model.

[0039] 2. Impregnate the coagulant: impregnate the glove liner with the coagulant, the immersion time is 20-30s, the solvent of the coagulant is water, the solute and its weight content in the solvent are 30-40wt% calcium nitrate, 0.1 - 0.5 wt% defoamer.

[0040] The role of the coagulant is to prevent penetration during the subsequent dipping. When the glove liner is immersed in the coagulant, a water film will be formed on the surface of the glove liner. Adding 0.1-0.5wt% defoamer can eliminate the foam generated when the glove is immersed in the coagulant.

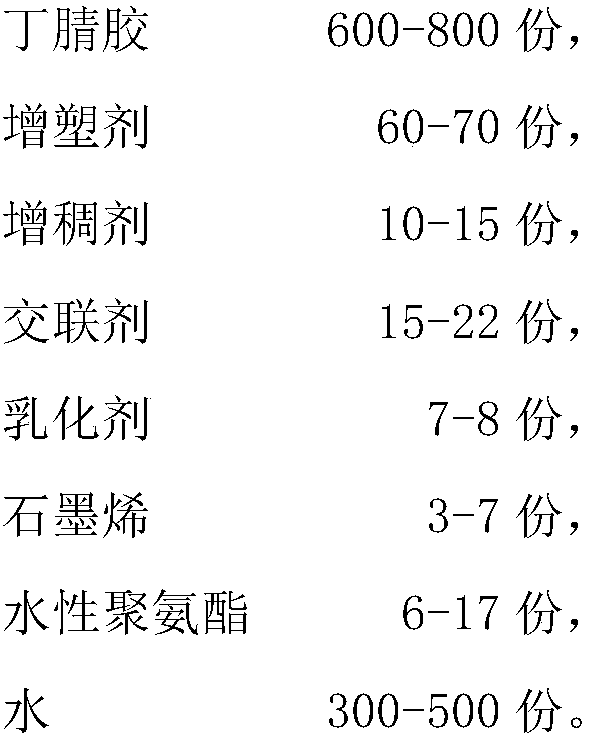

[0041] 3. Dipping: The glove liner is fully immersed in the graphene-nitrile rubber composite slurry. The latex viscosity is 600-700cp, and the dipping time is 10-15s. The graphene-...

Embodiment 1

[0053] The embodiment of the present invention discloses a preparation method of graphene-nitrile latex scrub gloves, said method comprising the steps of:

[0054] S1. Set liner: Put the glove liner on the hand model.

[0055] S2. Impregnate coagulant: impregnate the glove liner with coagulant, the immersion time is 20s, the solvent of the coagulant is water, the solute and its weight content in the solvent are 30wt% calcium nitrate, 0.1wt% defoaming agent.

[0056] S3, dipping: the glove liner is fully immersed in the graphene-nitrile rubber composite slurry, and the dipping time is 10-15s. The graphene-nitrile rubber composite slurry can be obtained by the following method: 600 wt. One part of nitrile rubber is put into stirring device, stirs with the speed of 30r / min, adds successively 60 parts by weight of plasticizer, 10 parts by weight of thickener, 7 parts by weight of emulsifier, 6 parts by weight of waterborne polyurethane, 15 parts by weight of crosslinking agent, ...

Embodiment 2

[0063] The embodiment of the present invention discloses a preparation method of graphene-nitrile latex scrub gloves, said method comprising the steps of:

[0064] S1. Set liner: Put the glove liner on the hand model.

[0065] S2. Impregnate coagulant: impregnate the glove liner with coagulant, the immersion time is 22s, the solvent of the coagulant is water, the solute and its weight content in the solvent are 33wt% calcium nitrate, 0.2wt% defoaming agent.

[0066] S3, dipping: the glove liner is fully immersed in the graphene-nitrile rubber composite slurry, and the dipping time is 11s. The graphene-nitrile rubber composite slurry can be obtained by the following method: 650 parts by weight of nitrile Nitrile glue is put into stirring device, stirs with the speed of 32r / min, adds 63 parts by weight plasticizers successively, 11 parts by weight thickeners, 7 parts by weight emulsifiers, 10 parts by weight of water-based polyurethane, 17 parts by weight of crosslinking agent,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com