Additive for prefabricated structural concrete and prefabricated structural concrete

A technology of concrete and additives, which is applied in the field of civil engineering, can solve the problems of low utilization rate of prefabricated concrete and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment, the additive of a kind of prefabricated structural concrete of the present invention and prefabricated structural concrete are described further:

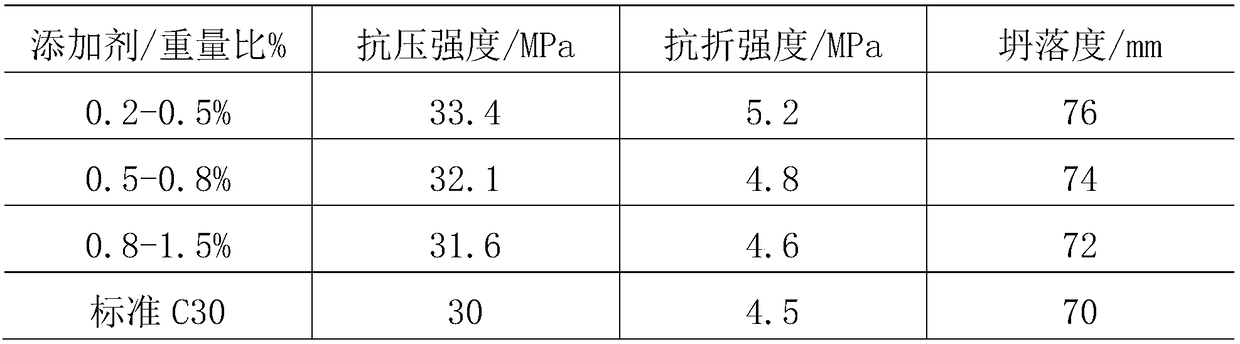

[0029] Compressive strength and flexural strength are important performance indicators of concrete. According to the provisions of "GBJ81-85 Test Method for Mechanical Properties of Ordinary Concrete", the compressive strength, flexural strength and compressive strength of concrete are measured by a pressure testing machine. The larger the value of flexural strength and flexural strength, the stronger its ability to resist damage. Slump is an important index to measure the workability of concrete. The larger the slump value, the better the plasticity and pumpability of the concrete, that is, the better the fluidity and cohesion of the concrete.

[0030] An additive for prefabricated structural concrete, the raw materials are calculated by weight percentage, including the following compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com