MBR membrane set device hoisting system of membrane workshop of buried sewage treatment plant and application of MBR membrane set device hoisting system

A technology of sewage treatment plant and membrane unit, which is applied in the field of water treatment, can solve the problems of long lifting operation, collision of obstructions, complicated lifting process, etc., so as to optimize the lifting process, reduce the transportation load, and reduce the transportation effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples are used to explain the technical solution of the present invention non-limitatively, and the protection scope of the present invention is not limited to the scope described in the examples.

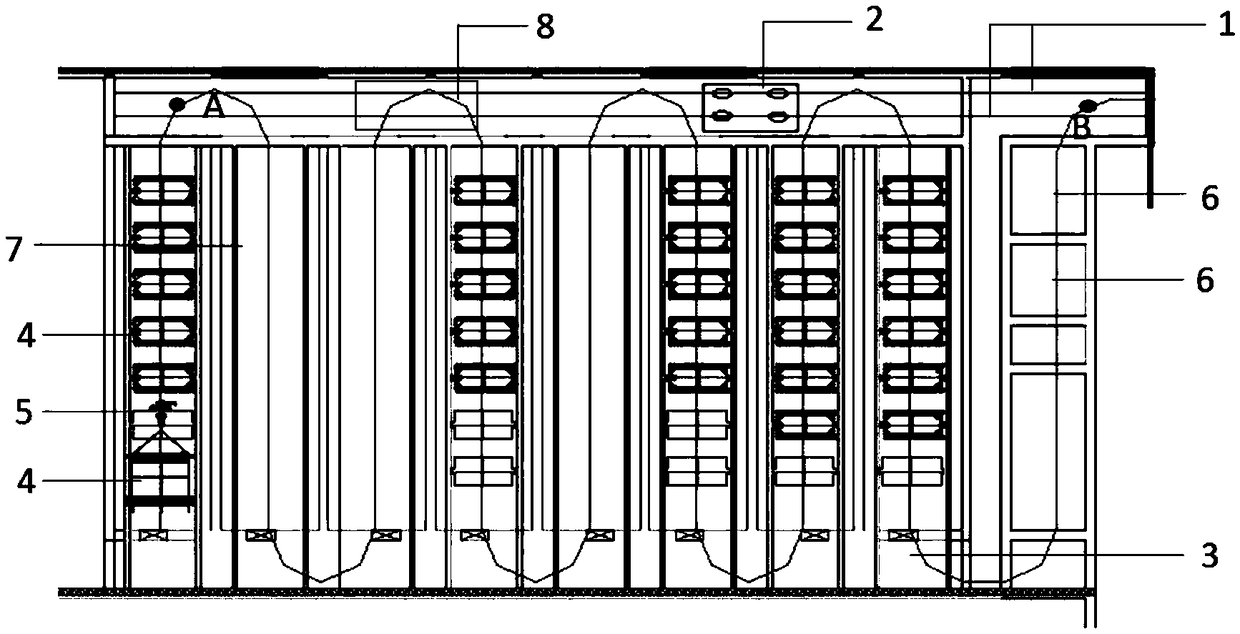

[0029] Such as figure 1 As shown, there are eight membrane pool corridors 7 and one cleaning tank 6 in the membrane workshop of a certain buried sewage treatment plant. Along the horizontal direction, from left to right, there are No. 1 corridor to No. 8 corridor respectively. There are guardrails around the road and columns between the corridors. The corridor is in the buried mode.

[0030] Along the horizontal direction, a pair of ground straight tracks with a span of 1 meter are arranged in the pedestrian walkway area on the longitudinal side of the membrane pool corridor and the cleaning pool. The track is equipped with an electronically controlled track-type flatbed car, which is connected to the electronic control device through cables to realize elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com