Transfer vehicle for resistors without brackets

A turnover car and resistance technology, applied in trolleys, motor vehicles, supporting parts, etc., can solve the problems of high cost, non-environmental protection, waste, etc., and achieve the effects of low cost, time saving and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

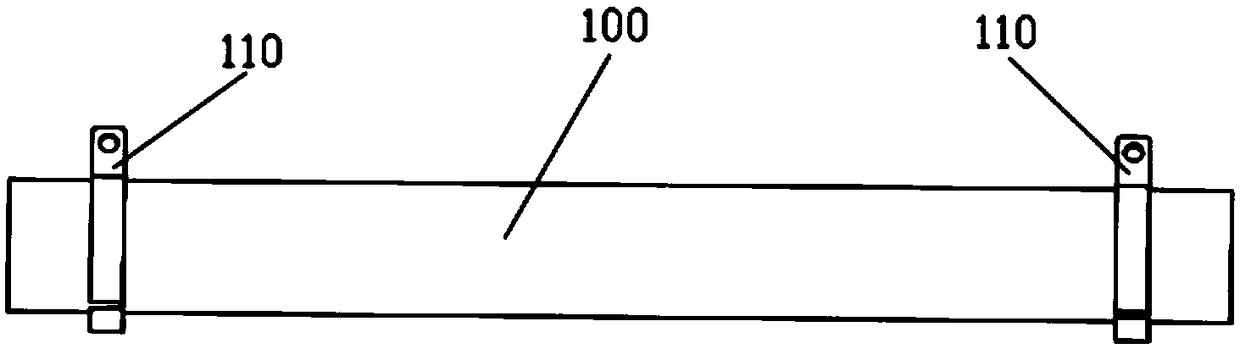

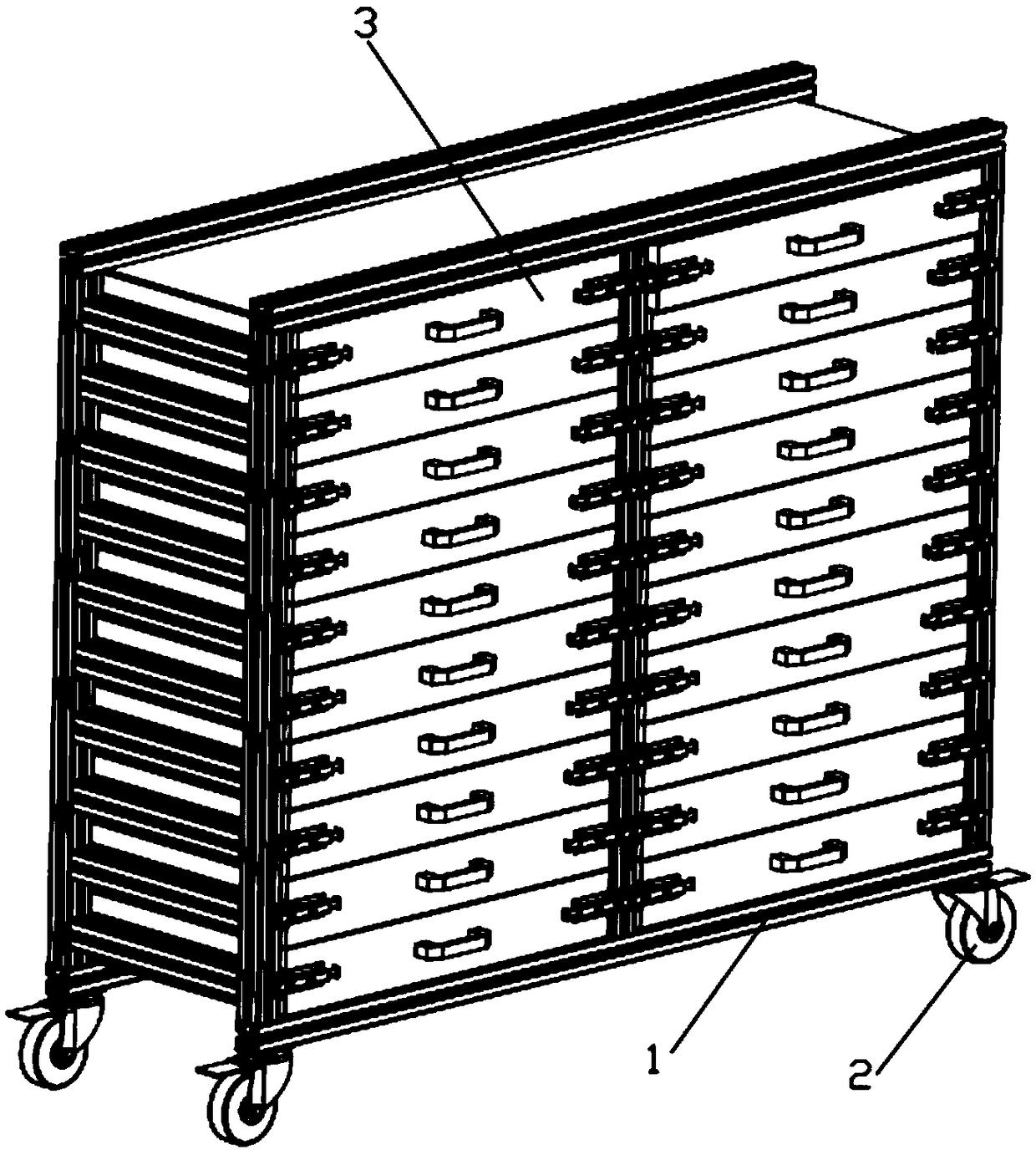

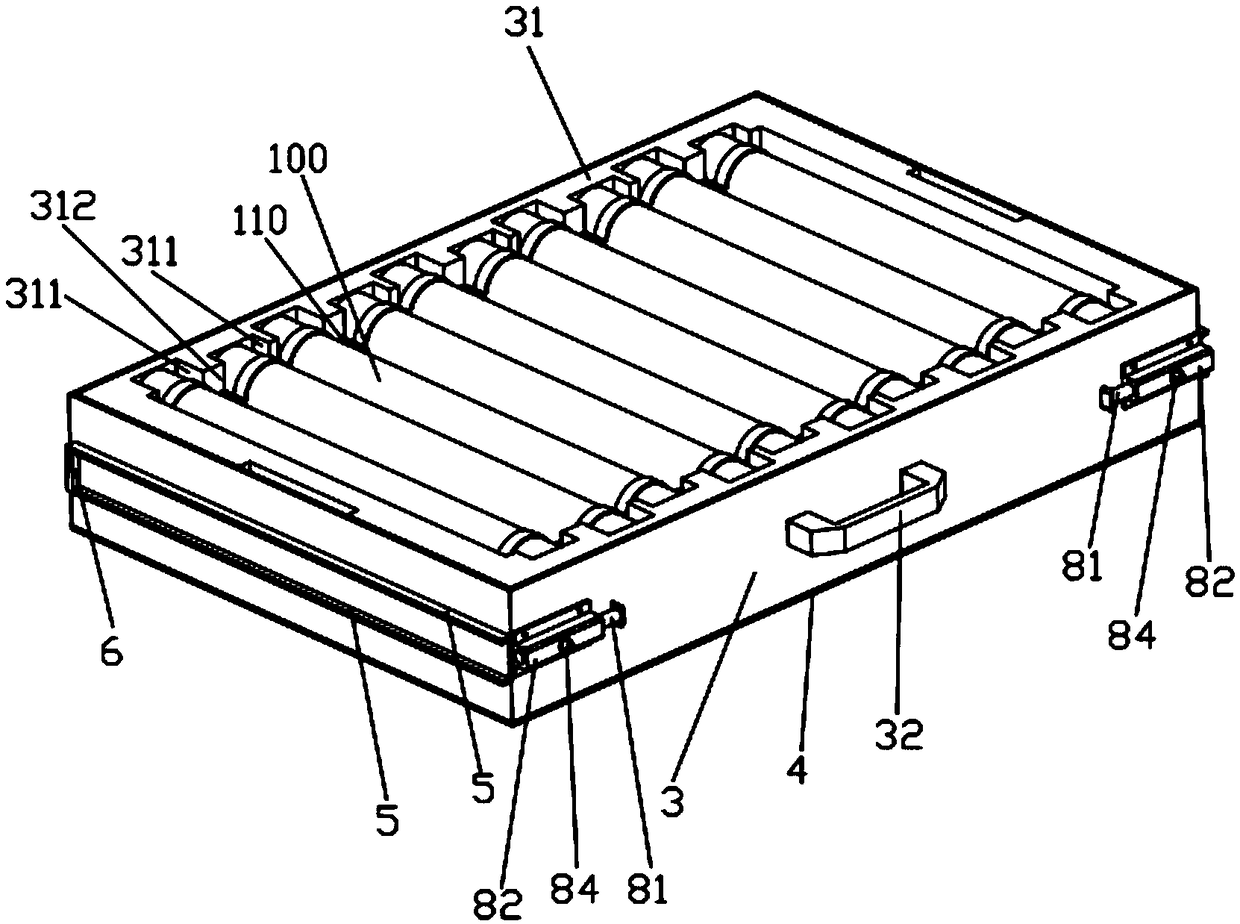

[0024] figure 2 The structure of the turnaround car is shown, the turnaround car includes a frame 1, and the bottom of the frame 1 is equipped with a universal wheel 2 with brakes, which facilitates the movement of the turnaround car to transfer the resistor 100 to the next process. The vehicle frame 1 is provided with two bearing areas, and each bearing area includes ten bearing positions evenly arranged vertically, and each bearing position is movably plugged with a drawer 3 . The revolving car in this embodiment has a total of 20 bearing positions, correspondingly provided with 20 drawers 3, each drawer 3 can hold ten resistors 100, and when the revolving car is fully loaded, it can transfer 200 resistors 100 at one time. In other embodiments, the number of carrying areas, the number of carrying positions and the number of resistors 100 placed in the dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com