Movable water-feeding robot protection cabinet and control method

A robotic and mobile technology, applied in railway auxiliary equipment and other directions, can solve problems such as aggravating the aging rate and affecting work efficiency, and achieve the effect of reducing the number of openings, ensuring the work progress, and slowing down the aging rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

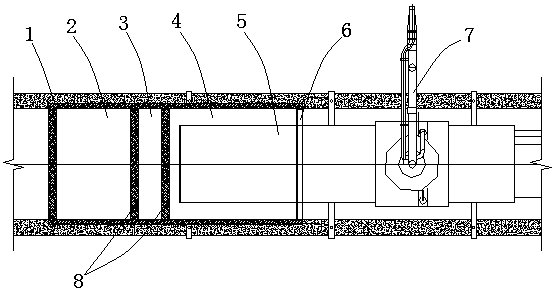

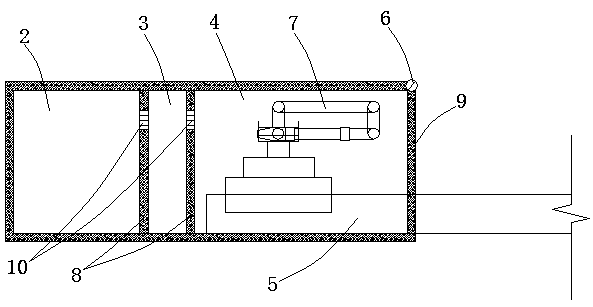

[0036] Such as figure 1 , figure 2 , image 3 and Figure 4As shown, this embodiment provides a mobile water filling robot protection cabinet, including a cabinet body 1, the side of the cabinet body 1 is connected with a door 9 that can be opened upwards, and the bottom of the door 9 is provided with a movable The mobile guide rail 5 for the water supply robot penetrates into the groove 12 inside the cabinet body 1. The inside of the cabinet body 1 is provided with a control cabinet and a water supply robot 7. The inner water-filling robot moves on the guide rail 5, and the water-filling robot 7 is electrically connected with the control cabinet. In this protective cabinet, when the water filling robot 7 performs the water filling operation, the door 9 on the cabinet body 1 is opened upwards, and the control cabinet controls the water filling robot 7 to move along the moving guide rail 5 of the water filling robot until it moves to a designated upper position outside the ...

Embodiment 2

[0049] On the basis of Example 1, such as Figure 5 As shown, in the present embodiment, the connection between the water feeding robot 7 and the control cabinet is carried out in a wireless communication mode for signal transmission, and the power line and the signal line between the water feeding robot 7 and the control cabinet are canceled, and the water feeding robot 7 The power supply then passes through the built-in DC power supply at the bottom of the water robot 7, and the end of the water robot moving guide rail 5 in the cabinet 1 is provided with a charging plate 13 for charging the DC power supply of the water robot 7, and the charging plate 13 and The DC power supply of the water-filling robot 7 can adopt contact charging or wireless charging. After the water-filling robot 7 has performed the water-filling operation, it will automatically return to the mobile water-filling robot protection cabinet for standby charging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com