a co 2 Nanocomposite catalyst for efficient conversion into cyclocarbonate and preparation method thereof

A nano-composite and cyclocarbonate technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve poor stability, Catalyst preparation costs are high, difficult to recycle, etc., to achieve the effect of easy removal, wide application range of substrates, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention provides a CO 2 A method for preparing a nanocomposite catalyst converted into cyclocarbonate with high efficiency, comprising the following steps:

[0039] (1) contacting the attapulgite powder with a modifier, centrifuging, washing, and drying the reaction product to obtain a solid powder;

[0040] (2) The solid powder is contacted and reacted with a metal salt, and then CO is introduced into the reaction system 2 , to obtain the pre-product;

[0041] (3) sintering the pre-product to obtain the nanocomposite catalyst;

[0042] The metal salts are rare earth salts and / or transition metal salts.

[0043] The technical idea of the present invention is to carry out composite reaction of attapulgite and metal salt to obtain a composite material of nano attapulgite and metal oxide; 2 The catalyst in the synthesis of cyclocarbonate has many advantages such as stable structure, no pollution to the product in the catalytic process, easy separation o...

Embodiment 1

[0066] a CO 2 A method for preparing a nanocomposite catalyst converted into cyclocarbonate with high efficiency, comprising the following steps:

[0067] S1: Add 30g of attapulgite powder to a 500ml two-necked bottle equipped with a mechanical stirring device, add 300ml of deionized water as a solvent, and then add 0.8g of NaPF 6 As a modifier; control the temperature at 25-55 ° C, mechanically stir and ultrasonically disperse for 4 hours, after the reaction is completed, cool down to room temperature, centrifuge the product, wash, and dry to obtain a solid powder;

[0068] S2: Take 2.5g of the above solid powder and put it into a single-mouth bottle, add 100ml of ultrapure water, disperse it ultrasonically, and then add 1.5mmol ZnCl 2 , magnetically stirred until it was completely dissolved, and introduced CO into the one-necked bottle 2 gas, fully reacted for 6 hours, centrifuged, washed and dried the product to obtain the pre-product;

[0069] S3: The pre-product is pla...

Embodiment 2

[0071] This embodiment is the same as the preparation method of the solid powder in Example 1, the difference is that in step S2, 1mmol ZnCl is added 2 and 0.5 mmol ErCl 3 ;specific:

[0072] S2: Take 2.5g of the above solid powder and put it into a single-mouth bottle, add 100ml of ultrapure water, disperse it ultrasonically, and then add 1mmol ZnCl 2 and 0.5 mmol ErCl 3 , magnetically stirred until it was completely dissolved, and introduced CO into the one-necked bottle 2 gas, fully reacted for 6 hours, centrifuged, washed and dried the product to obtain the pre-product;

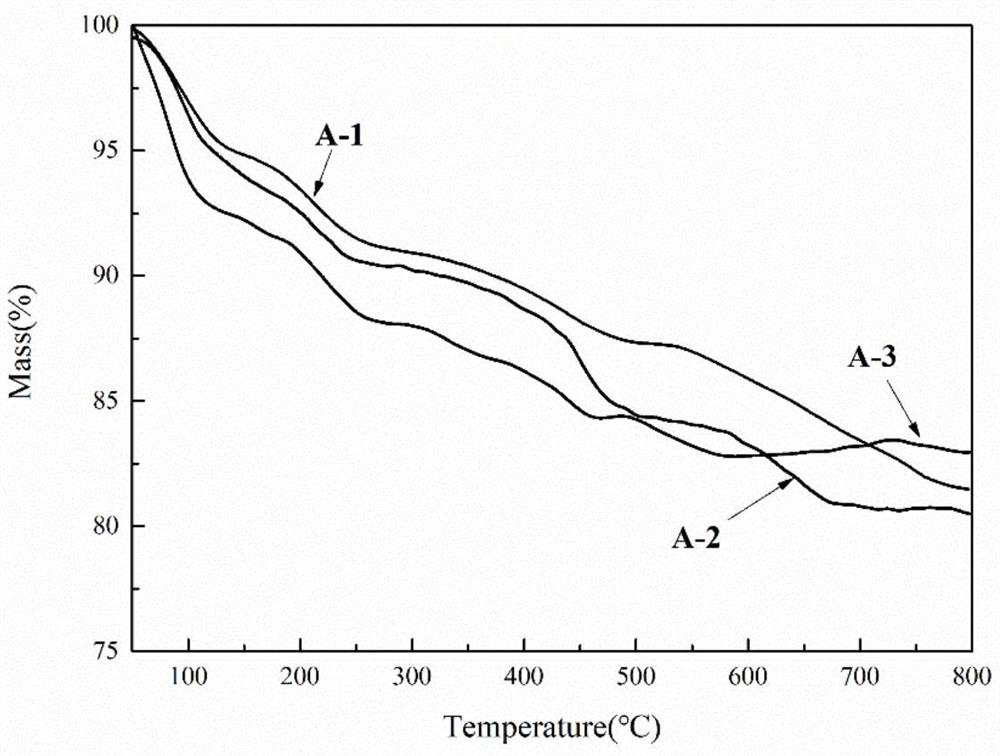

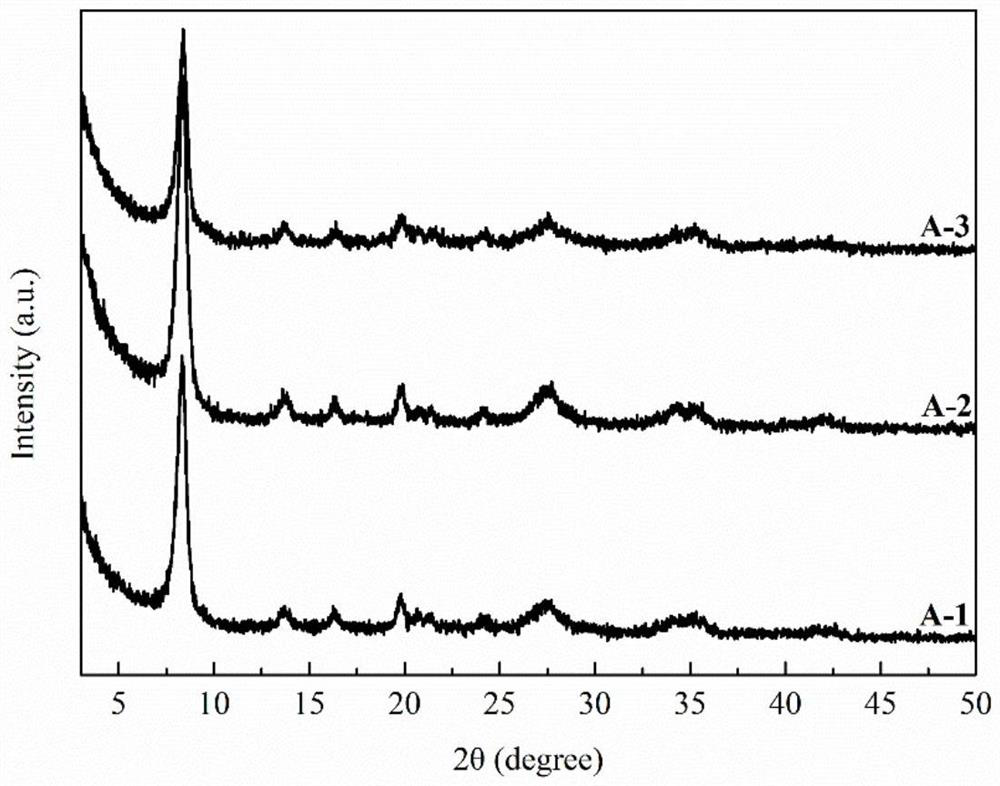

[0073] S3: The pre-product is placed in a high-temperature sintering furnace, and sintered at 800° C. for 2 hours to obtain the nanocomposite catalyst, which is designated as A-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com